Process for forming T-shaped welded nut by multistage cold former

A technology of welding nuts and cold heading machines, which is applied in the field of metal forging processing, can solve problems such as poor shape and size, flatness, concentricity, insecure strength, and expensive sheet metal, and achieve good operational safety and social environmental protection Sex, reduce labor intensity of workers, improve the effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

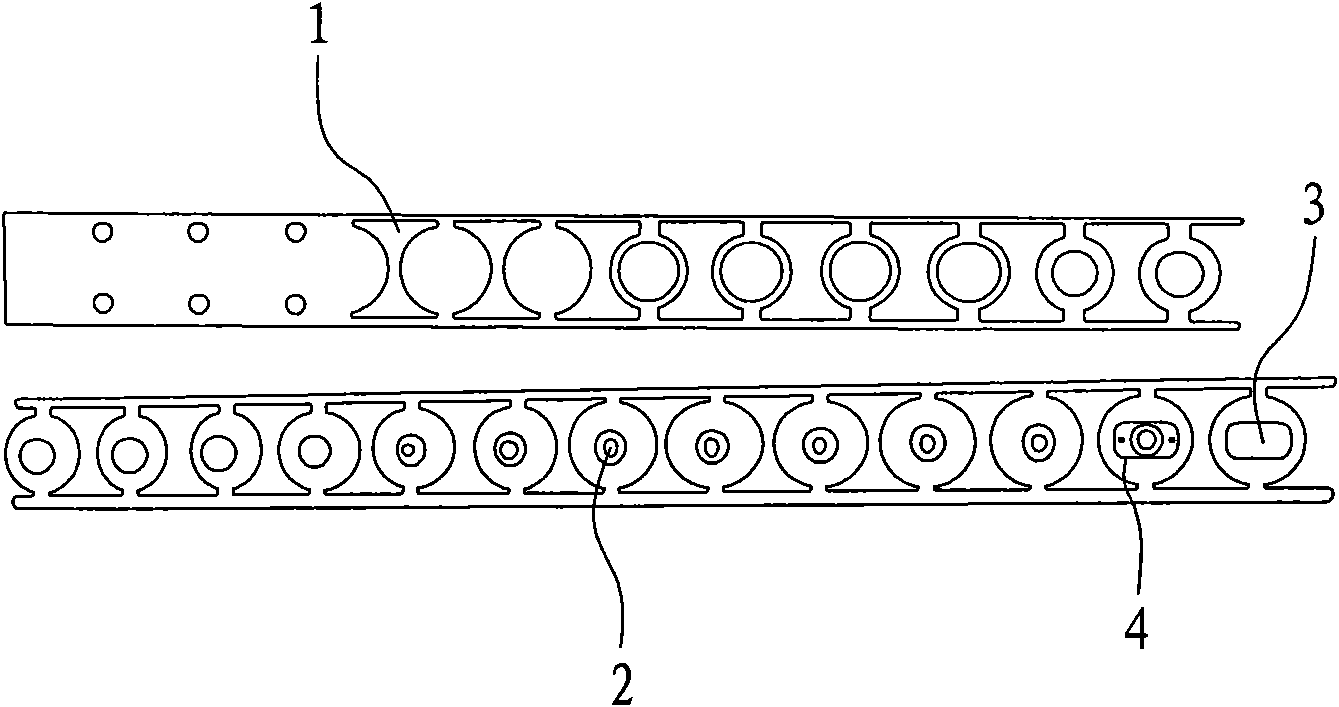

[0028] Please refer to Fig. 2, when the coil wire used in the present invention is cut, shaped, pre-formed, rim and weld leg pre-formed, rim and weld leg formed, punched and trimmed, there are automatic feeding, automatic pinching, etc. Operation, before explaining the manufacturing process of the present invention, the operation such as automatic feeding, automatic pinch device etc. is done an explanation.

[0029] A. Automatic feeding:

[0030] The automatic feeding device of cold heading machine mainly includes: cam, feeding rocker, ratchet, pawl and feeding wheel and other components. The cam drives the feed rocker to make the ratchet actuate the ratchet to rotate an angle θ. When the ratchet rotates θ, the feeding wheel will synchronously rotate the angle θ to feed the material, then the feeding wheel will be divided into 2π / θ equal parts to feed the material. The effective working diameter of the wheel is D, and the feeding length each time is πD÷(2π / θ)=Dθ / 2.

[0031] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap