Air shot with rotatable air outlet

An air cannon and exhaust port technology, which is applied in the field of air cannons, can solve problems such as affecting the utilization rate of air cannons, and achieve the effects of reducing the number of installations, improving the utilization rate, and increasing the working area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

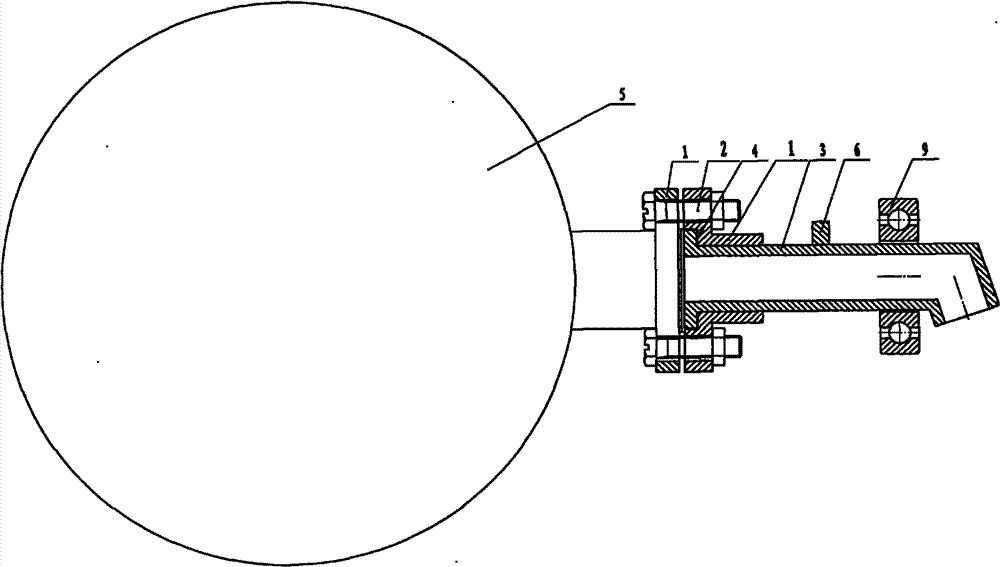

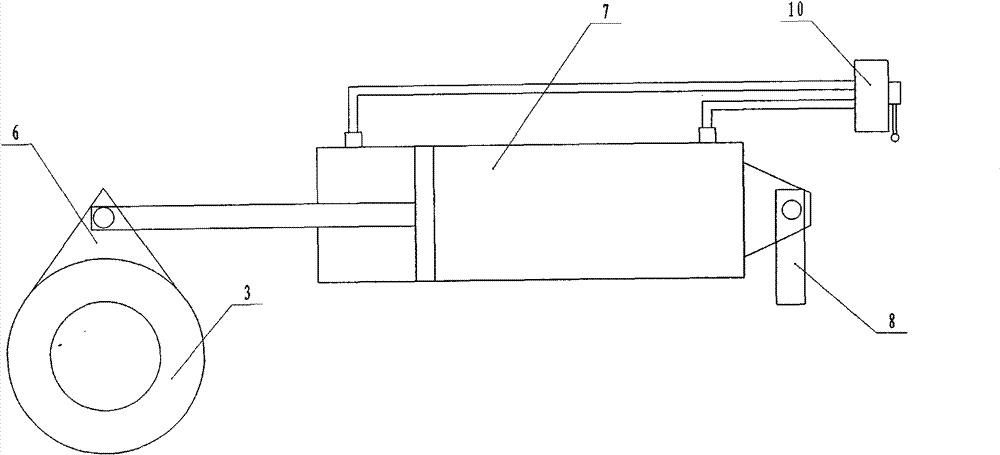

[0015] An air cannon with a rotatable exhaust port includes an exhaust pipe 3 , two flanges 1 and a sealing lubricating ring 4 . The two flanges 1 are buckled together and fixed with bolts 2 , an annular groove is formed between the two flanges 1 , and one of the flanges 1 is fixed at the gas outlet of the gas storage tank 5 . One end of the exhaust pipe 3 has a boss, and the boss is located in the annular groove, so that the exhaust pipe 3 can rotate around its center line. A sealing lubricating ring 4 is provided between the boss of the exhaust pipe 3 and the flange 1 . The sealing lubricating ring 4 adopts nylon. A support 6 is arranged on the exhaust pipe 3, and the support 6 is hinged with a piston cylinder 7, and the other end of the piston cylinder 7 is hinged with a fixed frame 8. The connecting rod of piston cylinder 7 can do reciprocating linear motion. During work, the air cannon is fixed to the fixed frame 8, and the movement of the connecting rod of the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com