Water treatment facility for fuel cell

A water treatment device and fuel cell technology, which is applied in the fields of fuel cells, fuel cell additives, electrolyte treatment of solid electrolyte cells, etc., can solve the problems of increased TOC in treated water, inability to achieve water conductivity, and increased TOC, and reduced The effect of chloride ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

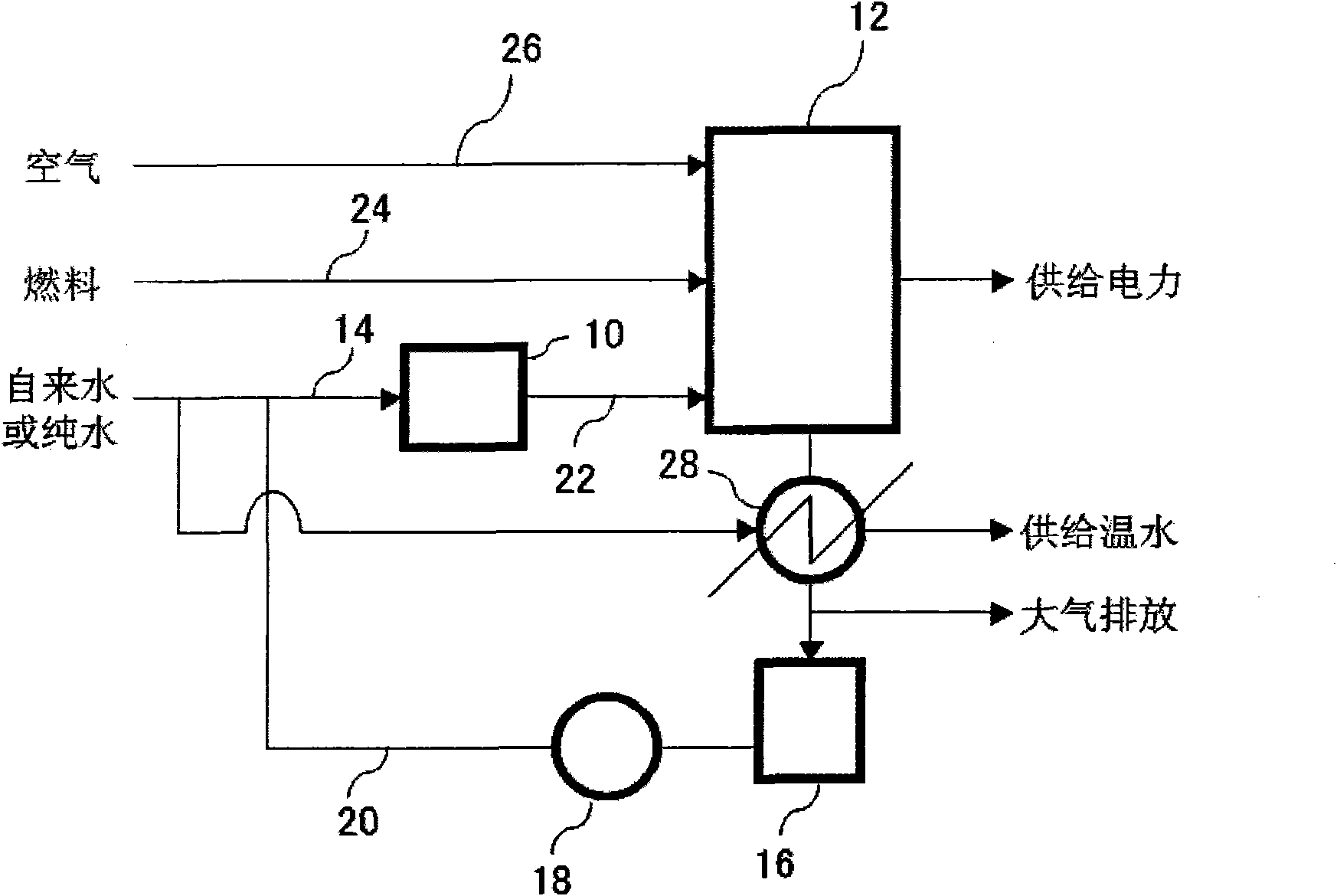

[0060] figure 1 The shown fuel cell water treatment device 10 includes a cartridge filled with an ion exchange resin. There can be one or more barrels. The ion exchange resin filled in the barrel is an anion exchange resin, or a mixed bed resin of anion exchange resin and cation exchange resin. Wherein, in the water treatment device 10 of the fuel cell, a cylinder filled with activated carbon or the like may be additionally provided in addition to the cylinder filled with the ion exchange resin.

[0061] The fuel cell water treatment device 10 of the present embodiment is mainly used to remove impurity ions in water supplied to the fuel cell 12 . As the water treated by the water treatment device 10 of the fuel cell, tap water (municipal water supply), pure water, condensed water generated by the power generation reaction of the fuel cell 12, etc. may be used.

[0062] Municipal water such as tap water is delivered to the water treatment device 10 of the fuel cell through t...

Embodiment approach 2

[0084] figure 1 The shown fuel cell water treatment device 10 has a cartridge filled with an ion exchange resin. There may be one cylinder or multiple cylinders. The ion exchange resin packed into the cartridge is an anion exchange resin, or a mixed bed resin of anion exchange resin and cation exchange resin. In addition, the fuel cell water treatment device 10 may additionally include a cylinder filled with activated carbon or the like in addition to the cylinder filled with the ion exchange resin. A water treatment device for a fuel cell needs to be heat-resistant and capable of being miniaturized. For example, JP-A-11-204123 discloses an example of using an anion exchange resin having a plurality of hydrocarbon groups in order to improve heat resistance. In addition, for example, JP-A-8-17457 discloses an example of optimizing the amount of cation exchange resin packed in a mixed-bed resin column in order to reduce the size of the device.

[0085] On the other hand, in ...

Embodiment approach 3

[0110] figure 1 The shown fuel cell water treatment device 10 may be equipped with a cartridge filled with ion exchange resin. There can be one or more barrels. The ion exchange resin filled in the cylinder is mainly a mixed bed resin of anion exchange resin and cation exchange resin, but if the cylinder is also installed on the upstream side, it can also be other anion exchange resins, or cation exchange resins, etc. single bed. In addition, the fuel cell water treatment device 10 may additionally include a cylinder filled with activated carbon or the like in addition to the cylinder filled with the ion exchange resin. In the mixed bed resin of cation exchange resin and anion exchange resin according to this embodiment, the average particle diameter of the cation exchange resin is preferably 0.2 mm or more and preferably 80% or less of the average particle diameter of the anion exchange resin. As explained above, since the specific gravity of the cation exchange resin and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Solid density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap