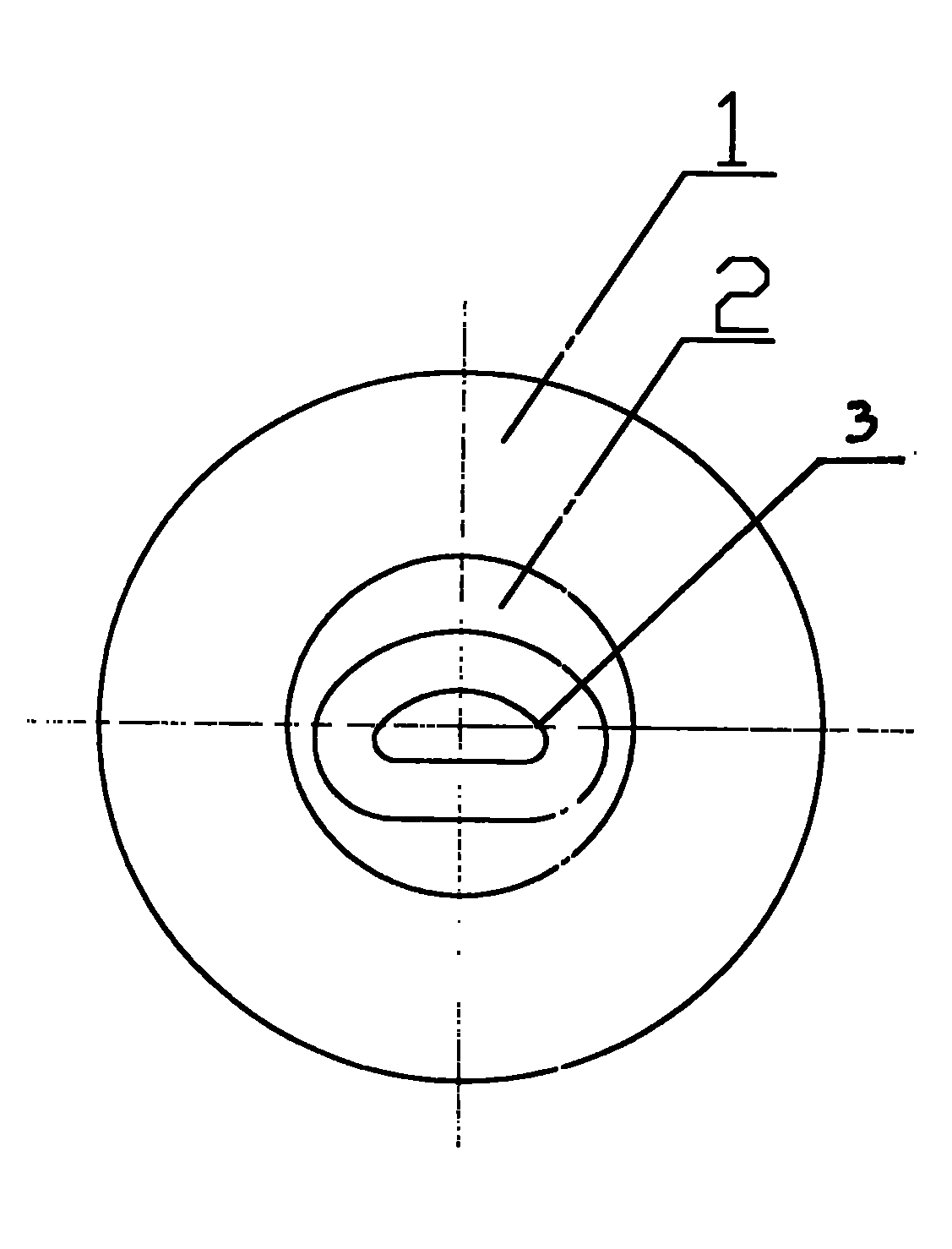

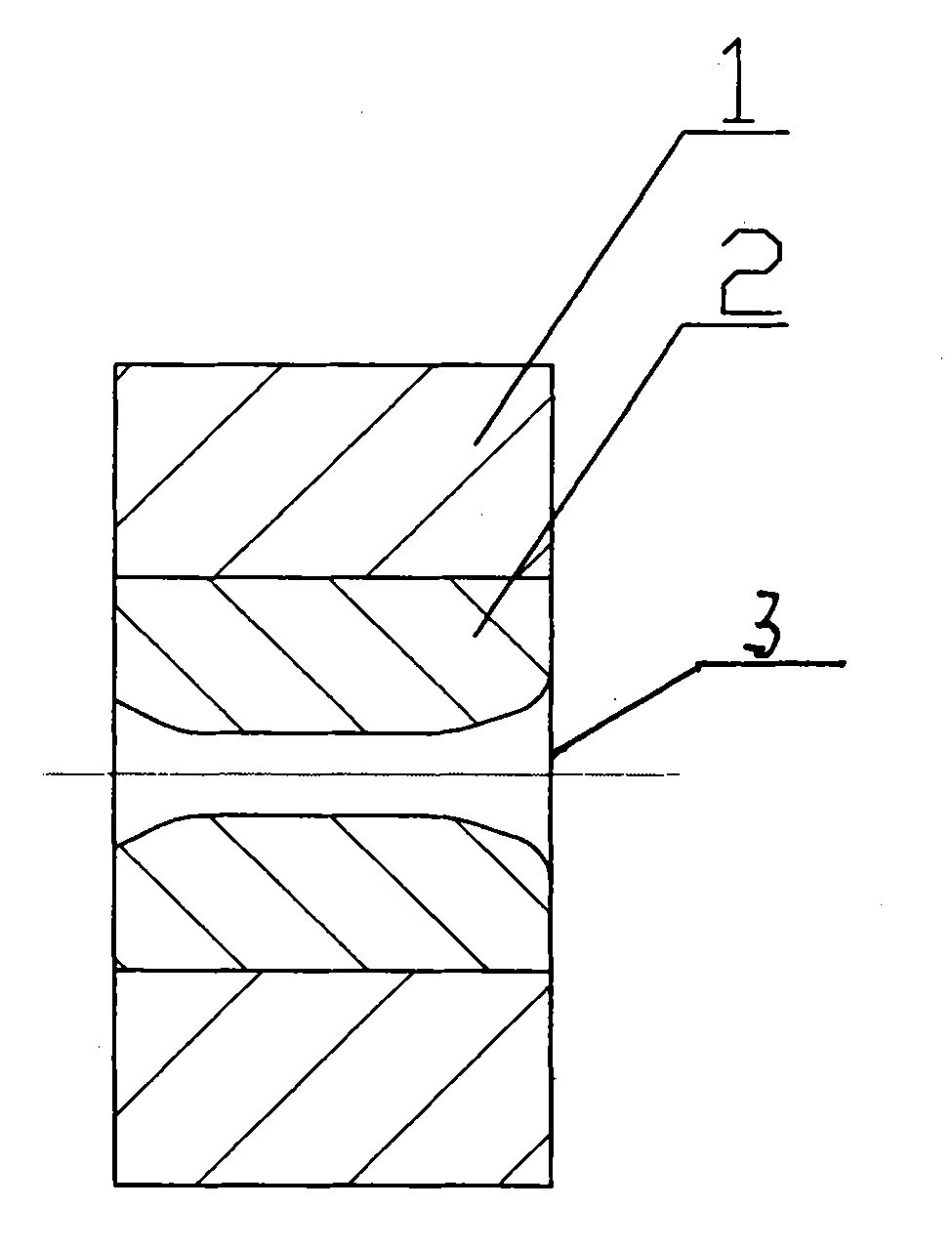

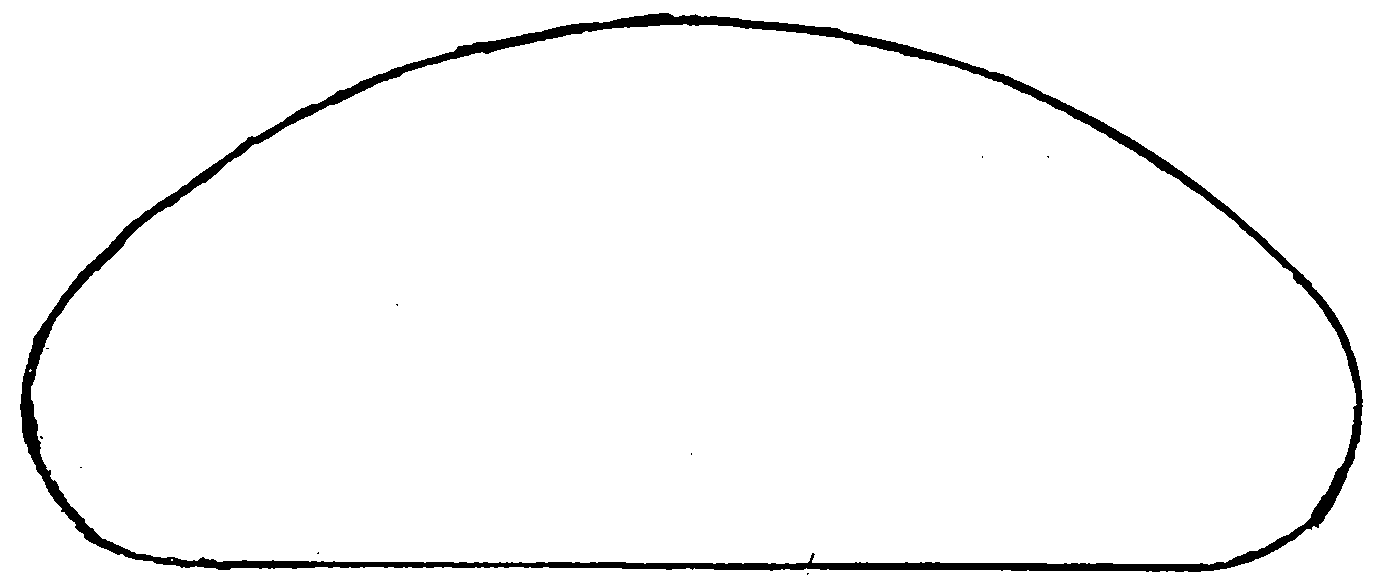

Method for manufacturing precision alloy semicircular steel wires

A precision alloy and manufacturing method technology, applied in the field of metal products, can solve the problems of high precision rolling rolls, serious environmental pollution, and high production costs, and achieve the effects of ensuring product yield, simple and stable process, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described and understood by non-limiting examples below.

[0033] A kind of manufacturing method of precision alloy semicircular steel wire of the present invention:

[0034] 1) Carry out raw material preparation according to the weight percent calculation of the contained composition of precision alloy semicircular steel wire, prepared three furnace embodiments, see as follows:

[0035] First furnace: C: 0.021%; Si: 0.30%; Mn: 0.50%;

[0036] P: 0.009%; S: 0.007%; Ni: 49.80%;

[0037] Fe: 49.32%.

[0038] Second furnace: C: 0.018%; Si: 0.28%; Mn: 0.45%;

[0039] P: 0.0052%; S: 0.0059%; Ni: 50.13%;

[0040] Fe: 48.99%.

[0041] The third furnace: C: 0.017%; Si: 0.25%; Mn: 0.38%;

[0042] P: 0.007%; S: 0.008%; Ni: 51.00%;

[0043] Fe: 48.12%.

[0044] 2) Melting: Clean the raw materials prepared above and put them into a vacuum induction furnace to melt the ingot. The temperature dur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap