Heald lifting control mechanism of loom

A control mechanism and loom technology, applied in cam shedding mechanism, weaving, textiles and paper making, etc. It can solve the problems of unstable shedding, unfavorable weft insertion, easy shuttle pinching, etc., and achieves good shedding stability and shed variation Small, good for weft insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

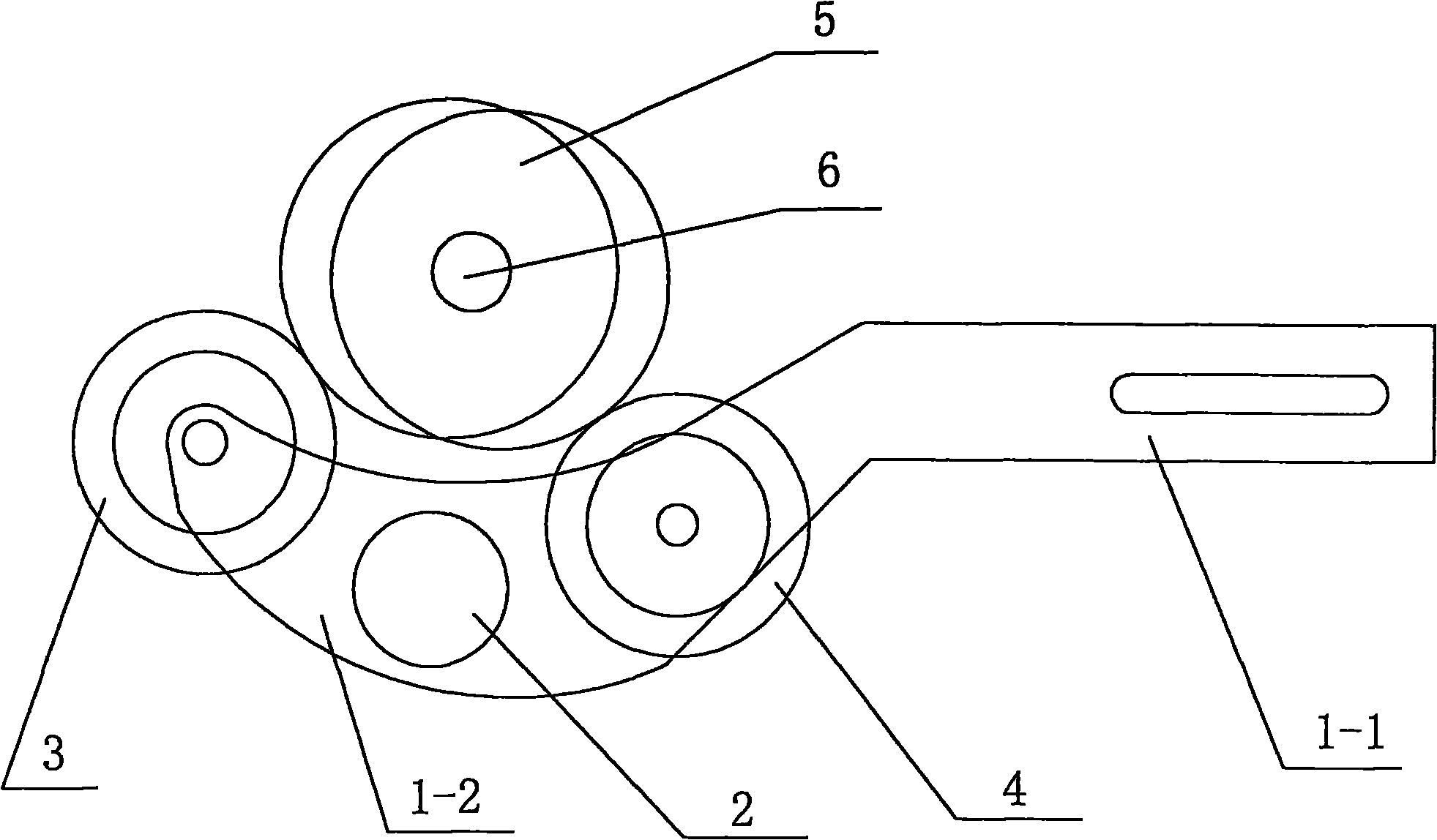

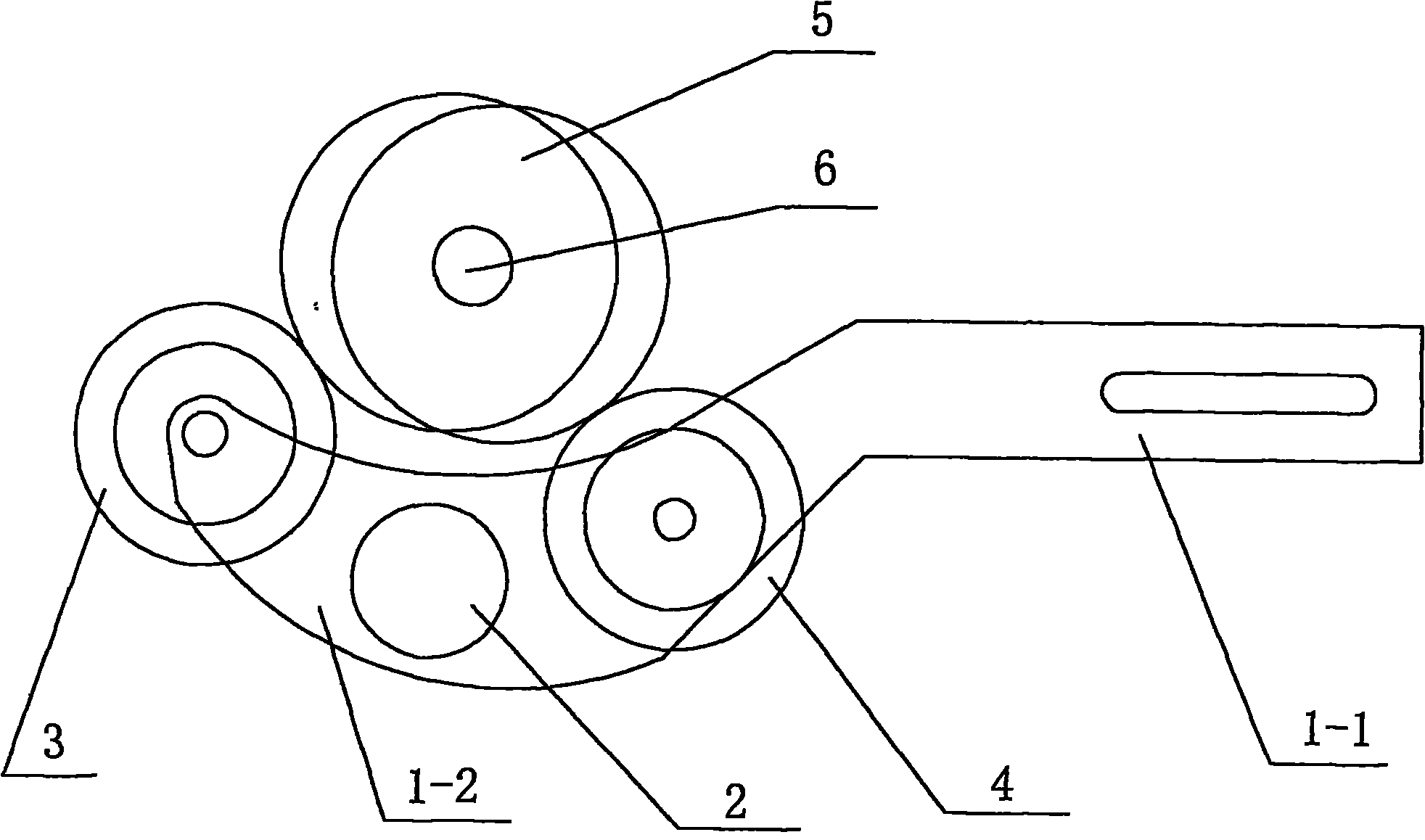

[0007] The heald lifting control mechanism of the loom includes a frame, a connecting rod, a connecting system, and a heald frame. The heald frame is connected to the connecting rod 1 through the connecting system, and the connecting rod 1 is arranged horizontally. -2, the hook body 1-2 is connected to one end of the straight handle 1-1, and the end of the straight handle 1-1 is connected to the above connection system; a rotating shaft 2 is fixed in the middle of the hook body 1-2, and the rotating shaft 2 passes through The bearings are supported on the frame, and the two ends of the hook body 1-2 are respectively connected with a bearing 3 and 4, and the two bearings 3 and 4 are circumscribed with a conjugate cam 5, and the conjugate cam 5 is connected with a crankshaft 6 , The crankshaft 6 is connected to the output end of the active rotation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com