Pressure transmitter with integrated encapsulation type sensor

A sensor and transmitter technology, applied in the field of pressure field measurement instruments, can solve the problems of increasing maintenance costs, inconvenience to on-site users, and prolonging maintenance time, so as to improve shock resistance, reduce on-site installation accessories, and improve on-site reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

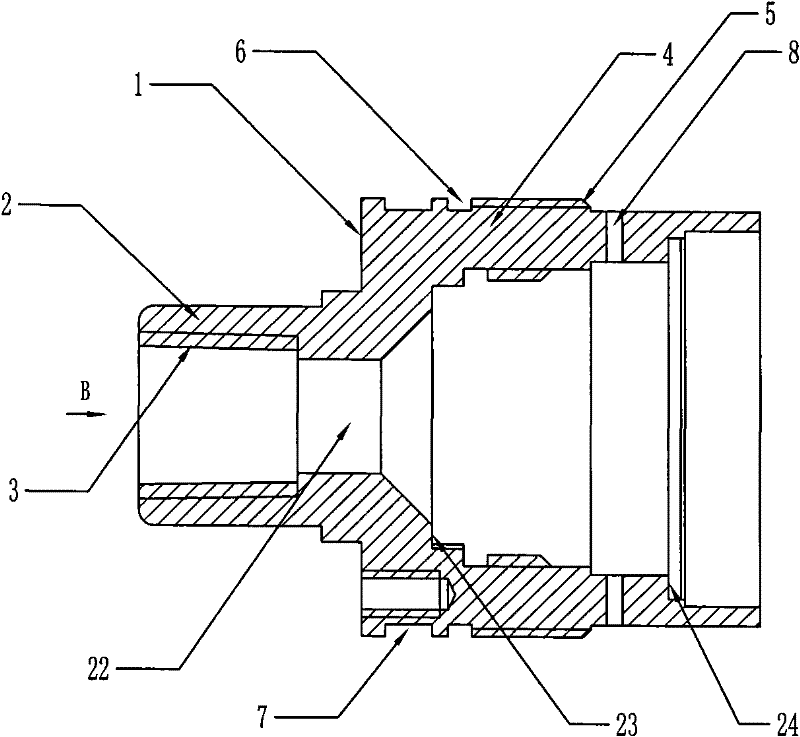

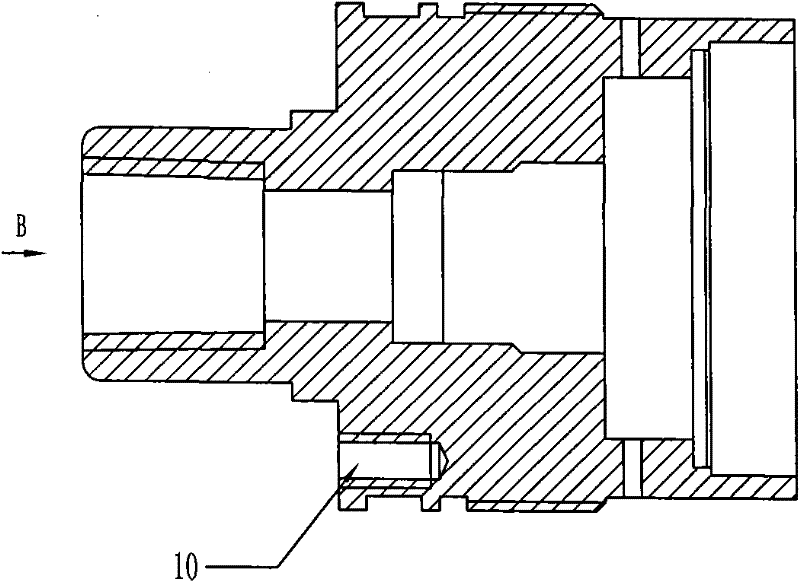

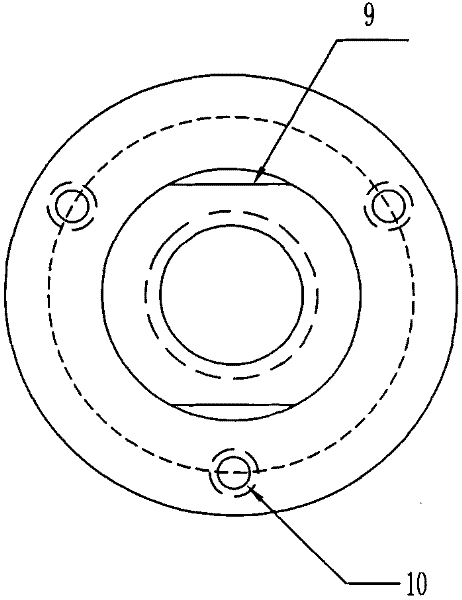

[0036] The flange structure of the pressure transmitter in Example 1 is as follows Figure 1 to Figure 3 shown.

[0037] The flange includes: a hollow flange surface 1, a ring-column interface end 2 protruding from the flange surface in the middle of the front side, a thread 3 inside the interface end 2, and two parallel opening grooves 9 oppositely arranged on the outside. At least three bracket fixing holes 10 are arranged on the flange surface, and threads are arranged inside the bracket fixing holes 10 . The rear side of the flange surface 1 is a hollow flange body 4, and an air vent 8, an annular shell connecting portion 5 and an annular sealing groove 6 are arranged on the outside thereof, and the sealing groove 6 has a built-in O-ring. The outer front end of the flange body 4 is provided with a shell fastening groove 7 . The inner wall of the flange body 4 is provided with a first platform 23 near the flange surface 1 and a second platform near the rear end of the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com