Testing method and device for gear destruction

A damage detection and detection device technology, applied in the direction of material magnetic variables, etc., can solve the problems of difficult evaluation and inspection, lack of on-site rapid detection methods and devices for bearing gear damage, and achieve consistent detection distance, small size and high detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

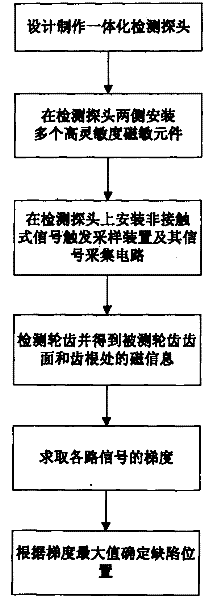

[0035] like figure 1 As shown, the specific implementation steps of the detection method of the present invention are as follows:

[0036] Step 1, design and manufacture an integrated detection probe, the shape of the detection area is consistent with the tooth profile of the tested gear teeth, and the size is slightly larger than the outer profile of the gear teeth, so that the gear teeth can pass the detection device smoothly.

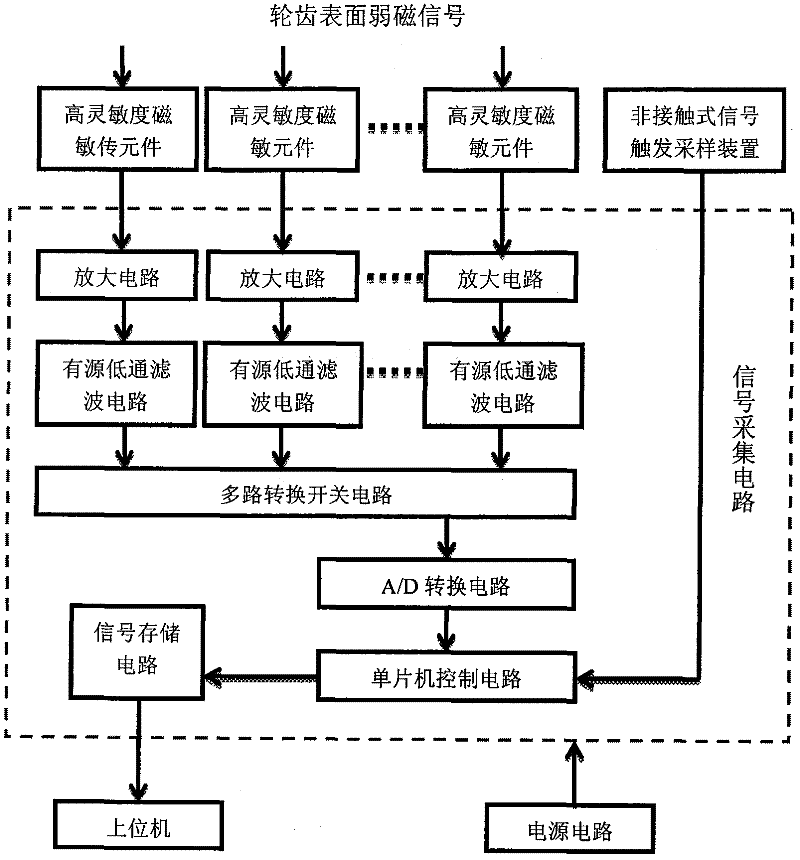

[0037] In step 2, a plurality of high-sensitivity magneto-sensitive elements are symmetrically distributed and installed on both sides of the integrated detection probe presenting the tooth profile shape of the gear teeth, so as to detect the changes of the magnetic field signal at the tooth surface and the tooth root.

[0038] In step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com