Novel foil winding type coil leading copper busbar

A technology of foil winding and coil, which is applied in the field of new foil winding coil lead-out copper bars, can solve the problems of large copper consumption and high production cost, and achieve the effect of small copper consumption and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with accompanying drawing:

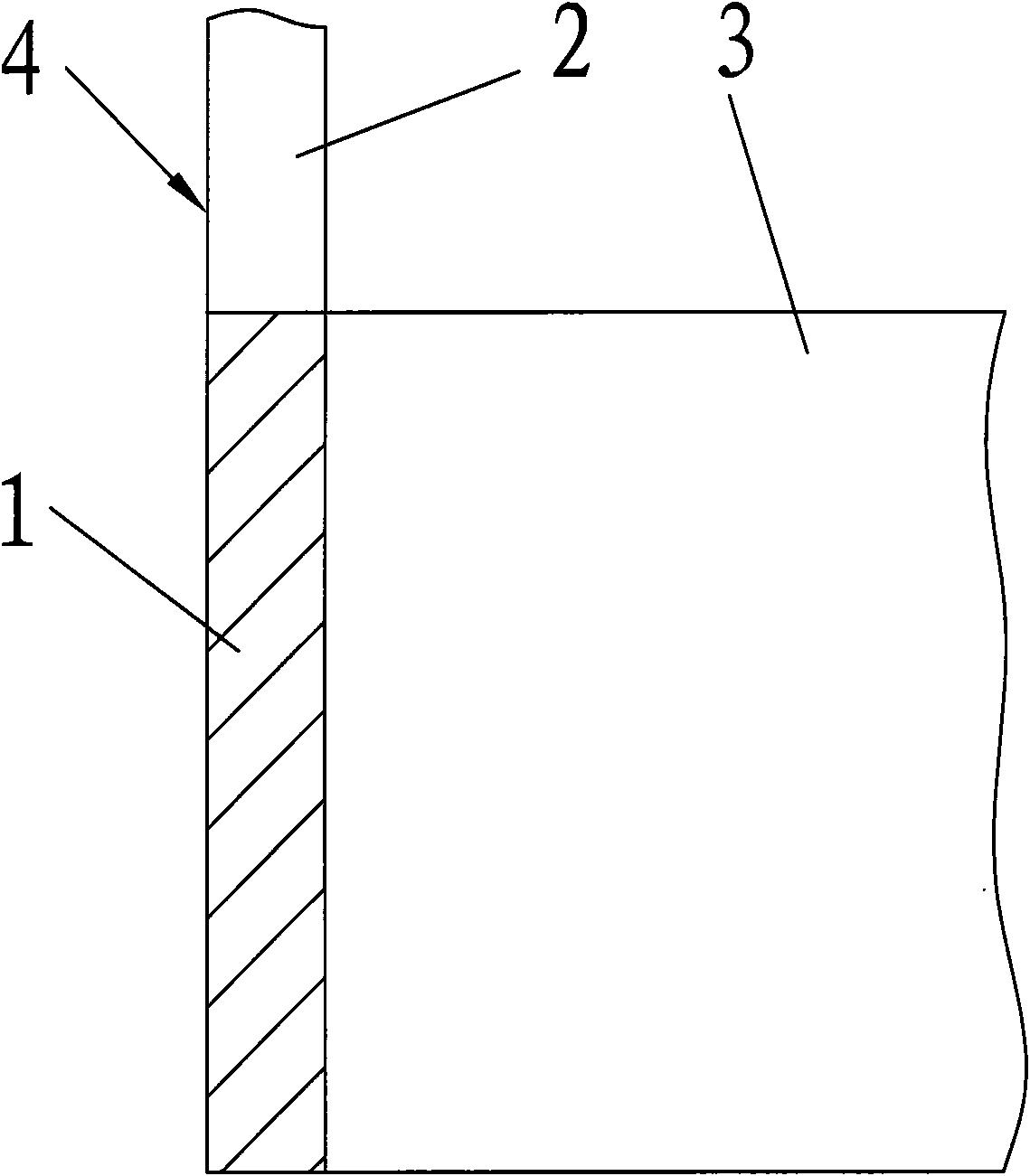

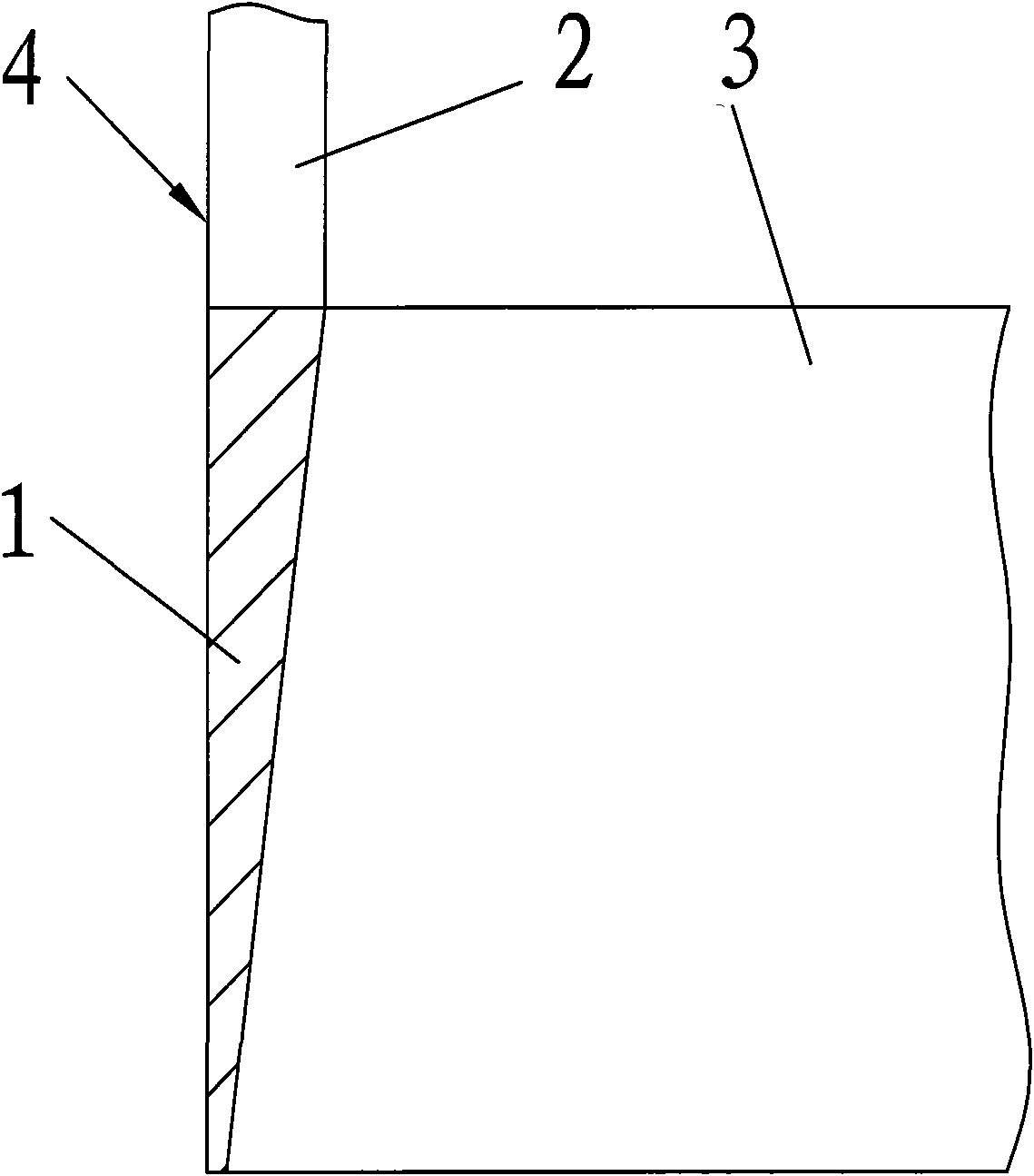

[0021] as attached image 3 And attached Figure 4 As shown in , a new foil-wound coil lead-out copper bar, the copper bar 4 includes a welding part 1 welded on the copper foil 3 and a lead-out part 2, and the width of the welding part 1 of the copper bar 4 decreases from top to bottom.

[0022] The welding part 1 of the copper bar 4 is an inverted right-angled trapezoid, or can be made into a right-angled triangle, and the lower end of the welding part has an end insulation 5 .

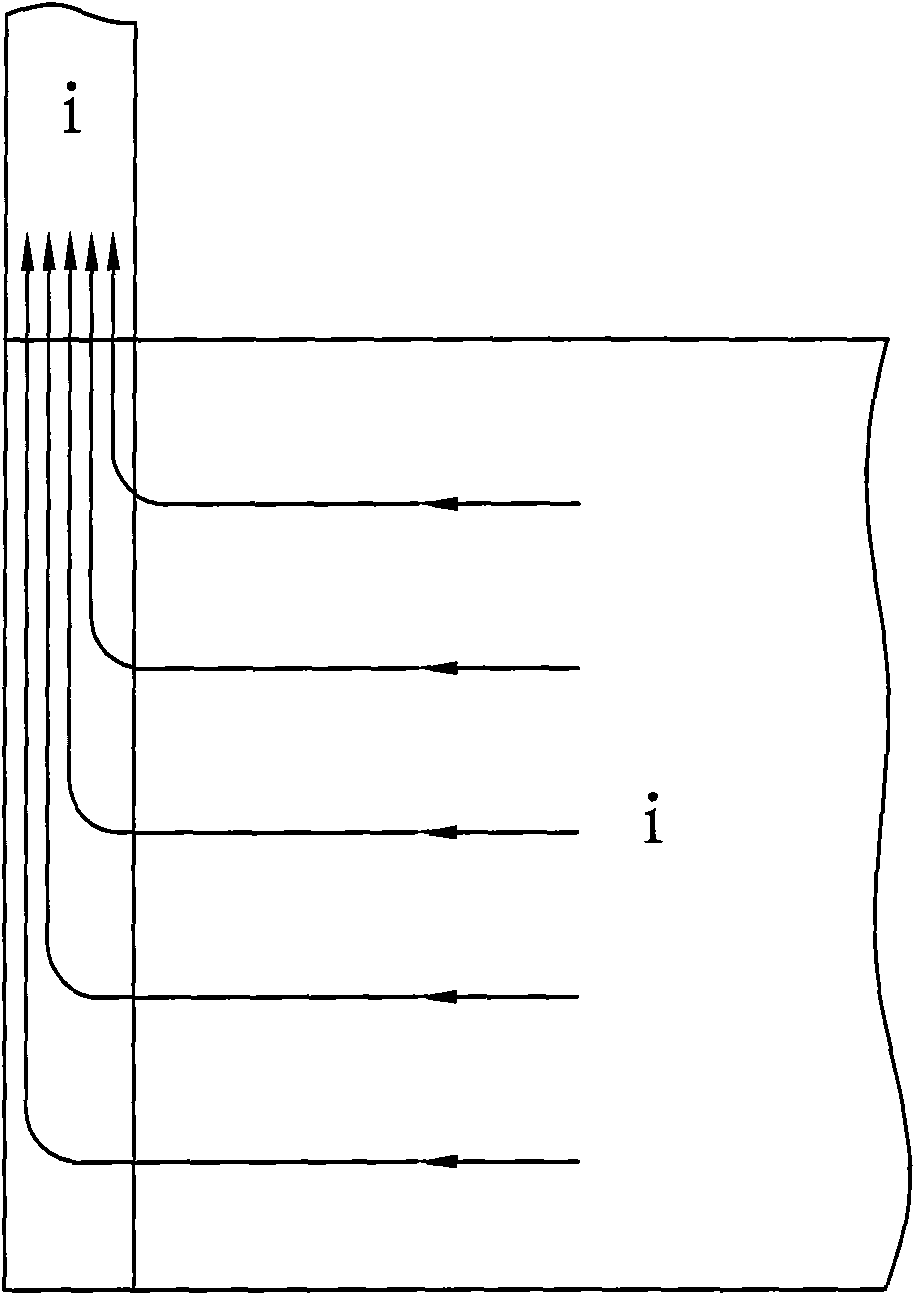

[0023] Tests have shown that compared with the traditional foil-wound coil lead-out copper bar structure, the current distribution in the lead-out bar of this lead-out copper bar structure is the same, and thus does not cause local overheating of the welding part 1 .

[0024] as attached Figure 7 As shown in , when making copper bars, the copper bars can be used on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com