Tooling used for processing brake drum

A brake drum and tooling technology, applied in the field of parts machining, can solve the problems of high scrap rate and low shift output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments.

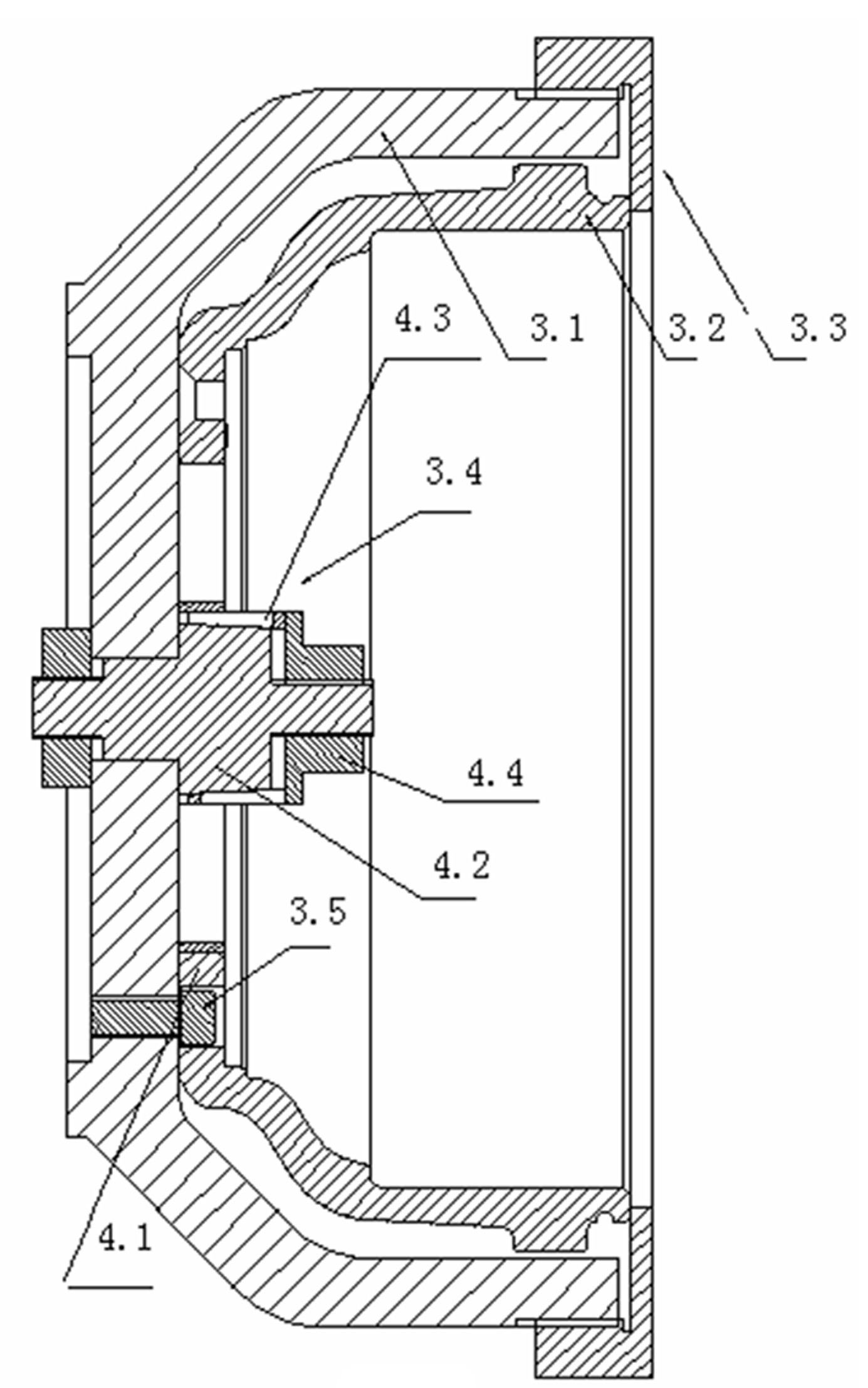

[0020] Such as image 3 , a tool for processing brake drums, including a sleeve 3.1, a cap 3.3 and a tension mandrel 3.4, the shape of the inner cavity of the sleeve 3.1 corresponds to the shape of the brake drum 3.2 to be processed; There is a hole at the center of the bottom of 3.1, and the expansion mandrel 3.4 is passed through the hole; the burst cap 3.3 is detachably set on the open end of the top of the sleeve 3.1;

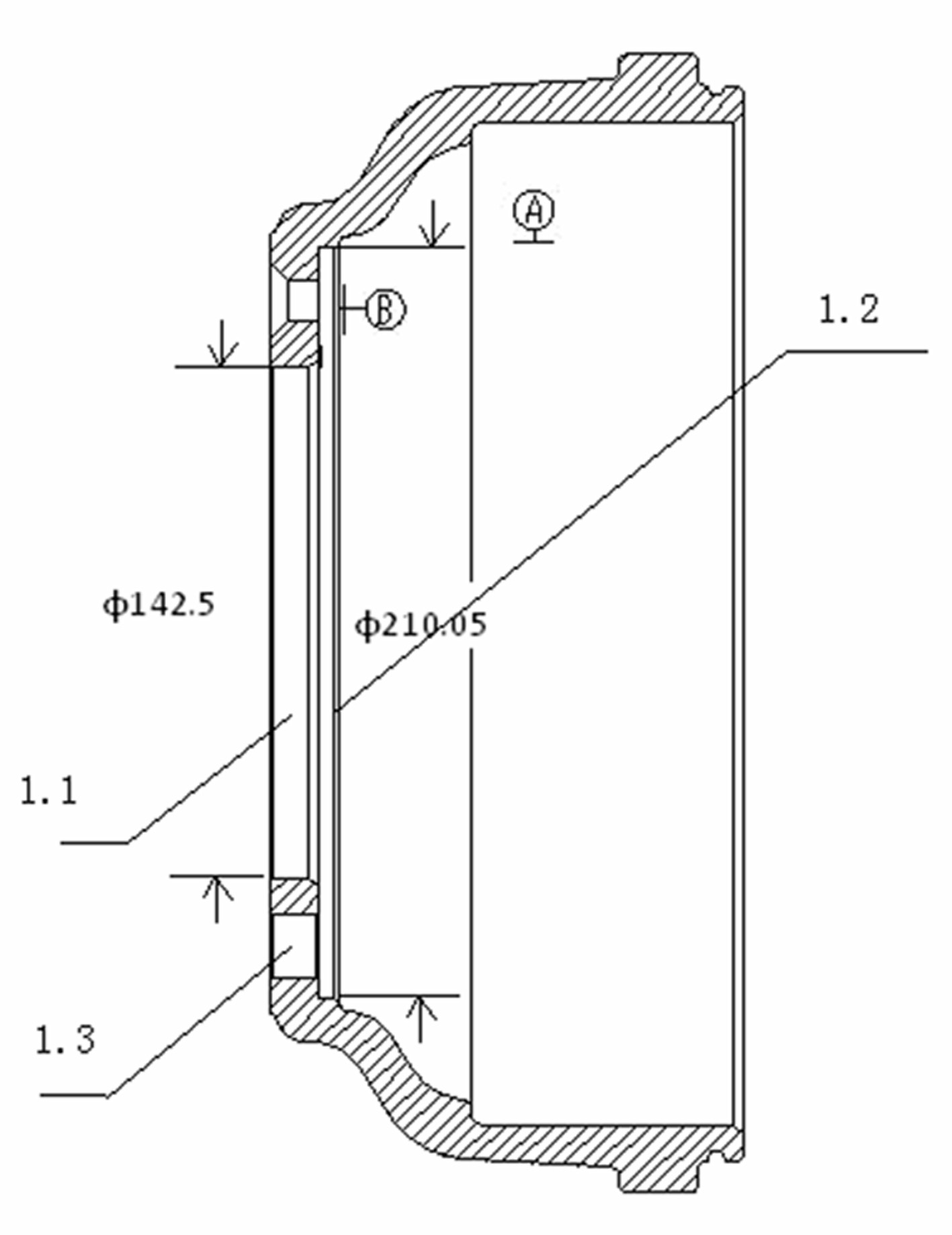

[0021] The expansion part of the tension mandrel 3.4 is inside the sleeve 3.1, and the shape of the expansion part corresponds to the shape of the inner wall of the first hole 1.1 at the bottom of the processed brake drum 3.2;

[0022] There is an opening in the middle of the burst cap 3.3, and the opening is larger than the size of the opening end of the processed brake drum 3.2.

[0023] The bottom of the sleeve 3.1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com