Casing frame of air handling unit

A technology of outer frame and air-conditioning box, which is applied in the direction of heating and ventilation cover/cover, etc., which can solve the problems of complex production, complex processing technology of aluminum alloy profiles, high cost, etc., and achieve easy processing and production, eliminate cold bridge phenomenon, and simple processing shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

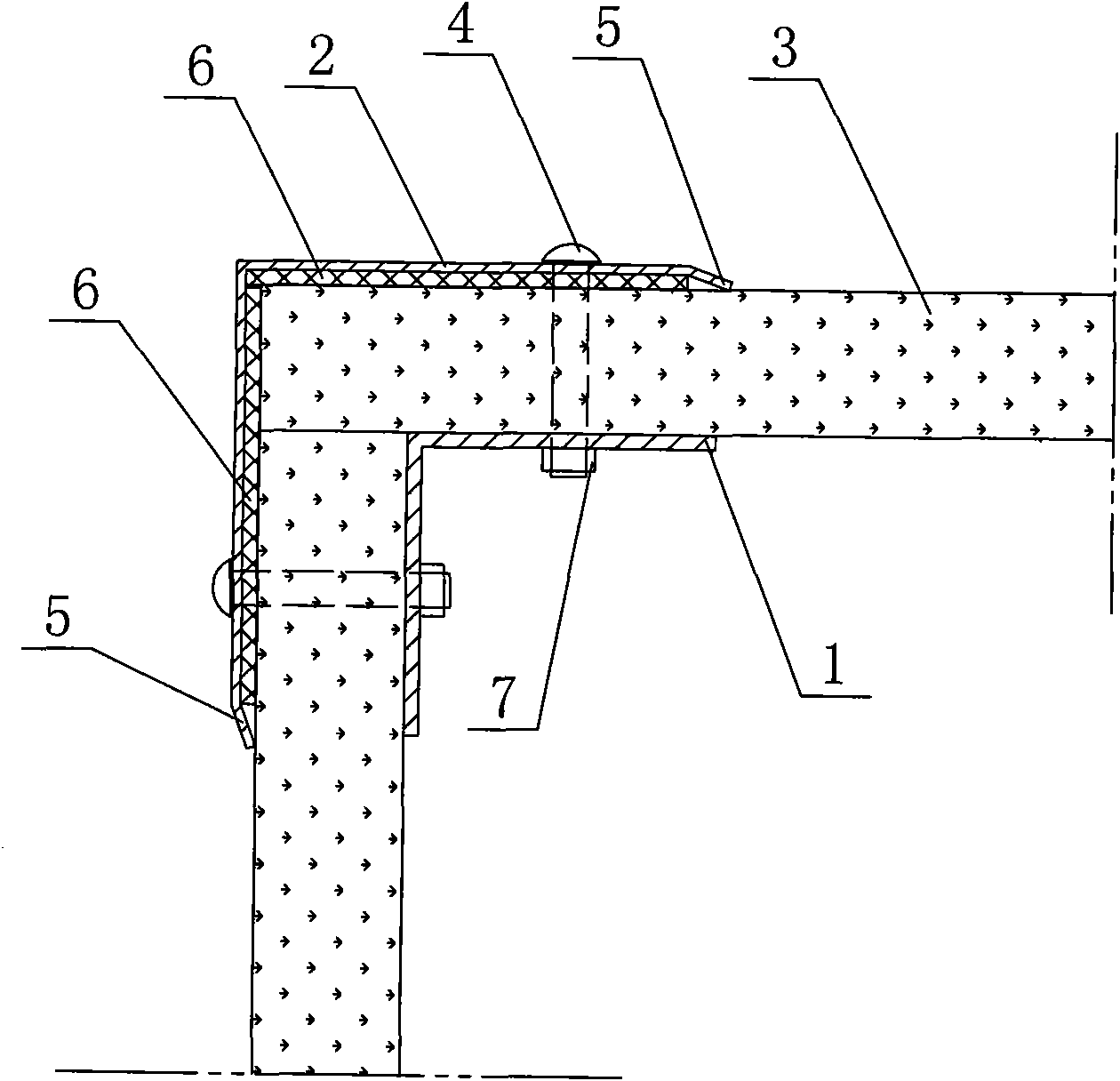

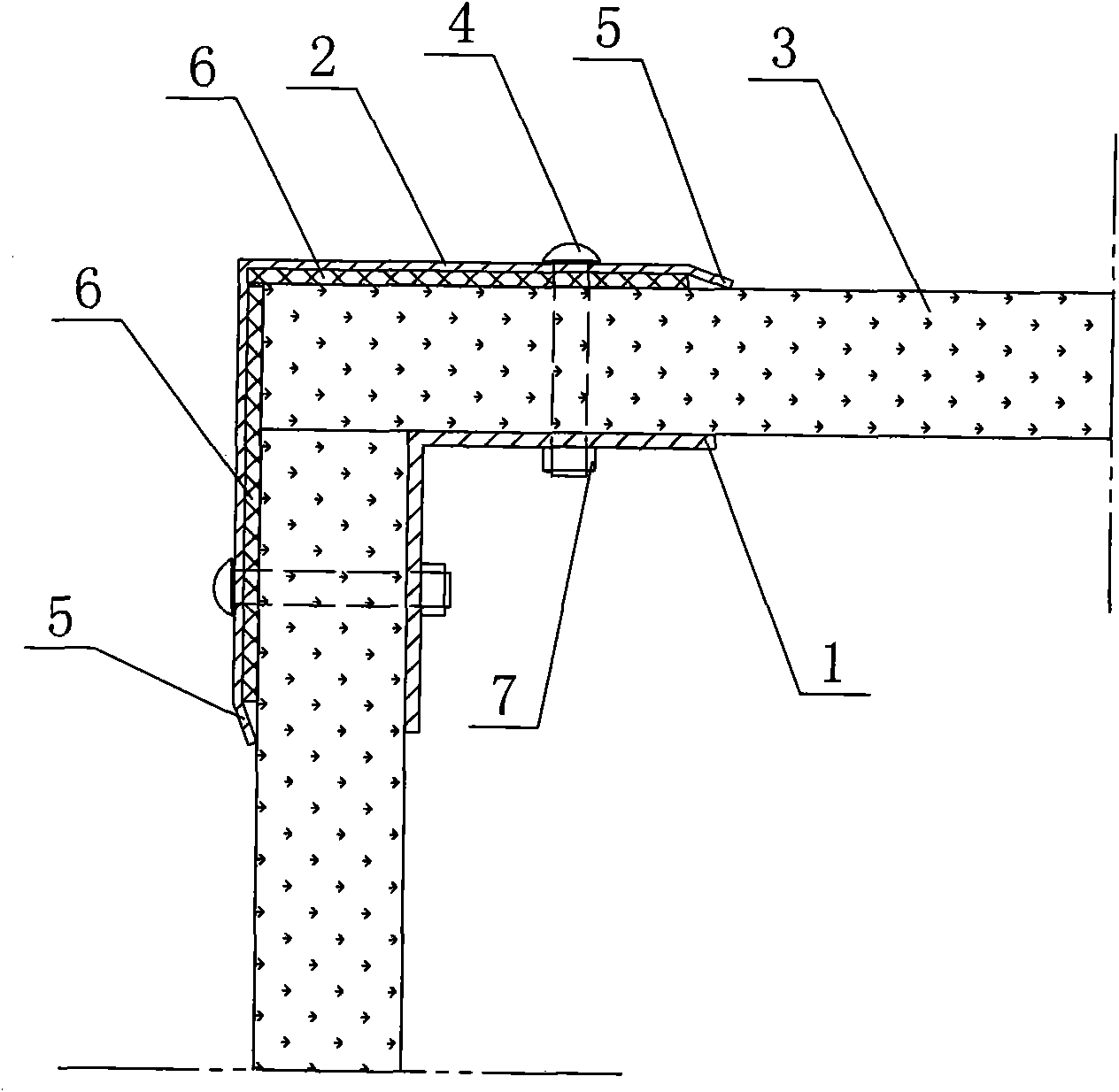

[0013] Please refer to figure 1 Shown, in this embodiment, a kind of shell frame of air conditioner, it comprises inner frame 1, outer frame 2 and polyurethane foam board 3, described inner frame 1 and outer frame 2 can adopt according to different use needs Made of materials such as stainless steel plate, aluminum plate or carbon steel plate, the inner frame 1 is installed inside the box body, the outer frame 2 is installed outside the box body, and a polyurethane foam board 2 is arranged between the inner frame 1 and the outer frame 2, Through the fixing bolt 4, the inner frame 1, the outer frame 2 and the polyurethane foam board 3 are locked with the fixing screw 7. The inner frame 1 and the outer frame 2 are both "L" shaped, and the inner frame 1 is assembled The urethane foam board 3 is tightly bonded, and the sealing gun glue or the sealing strip is pasted on the bonding surface, so that the entire inner frame 1 and the polyurethane foam board 3 can be well sealed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com