Structure of multifunction double-layer pressing steel plate roofing and laying method thereof

A profiled steel plate and laying method technology, applied to roofs, roofs using flat/curved panels, roof cladding, etc., can solve problems such as cold protection, heat insulation and sound insulation, and can easily ensure thermal insulation performance , The effect of less assembly and convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

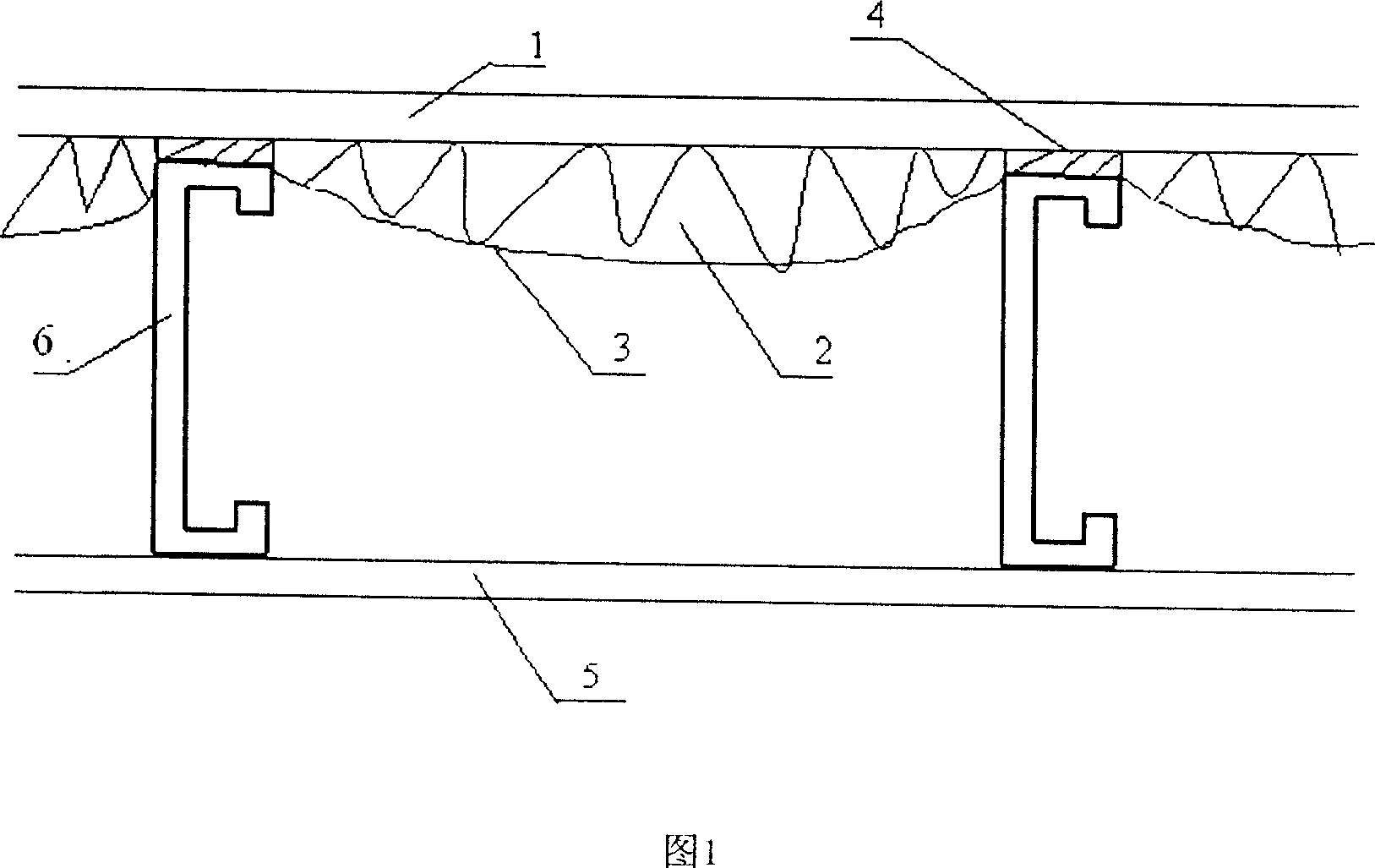

[0020] Embodiment of the present invention: as shown in Figure 1, steel wire mesh 3 is hung on the top surface of steel purlin 6, lays glass wool felt 2 on steel wire mesh 3, keeps the space between steel wire mesh 3 and upper laminated steel plate 1 and The thickness of the glass wool felt 2 is basically equal, so that the glass wool felt 2 after laying is neither compressed, but also can be close to the bottom surface of the upper laminated steel plate 1, so as to ensure the best effect of heat insulation; on the top surface of the steel purlin 6 Paste the rigid extruded foam as the heat insulation board 4, and fix the upper laminated steel plate 1 on the top of the steel purlin 6; nail the lower laminated steel plate 5 on the bottom surface of the steel purlin 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com