Sampling device for filter tank filler

A technology of sampling device and filter, which is applied in the direction of sampling device, etc., can solve the problems that affect the comprehensiveness and accuracy of experimental analysis, cannot obtain sufficient and sufficient samples, and it is difficult to accurately obtain fillers, etc., so as to improve the effective use length, The effect of light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

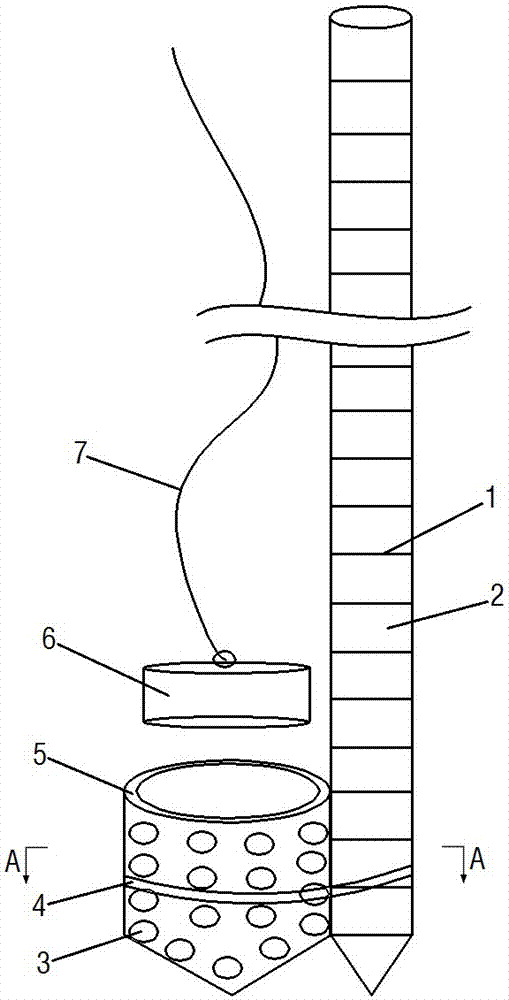

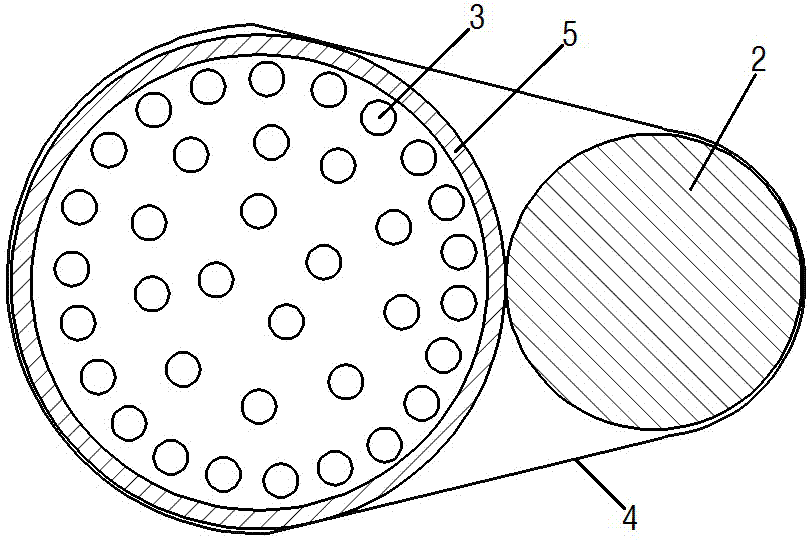

[0030] An example of a sampling device for filter packing is figure 1 and figure 2 As shown, it includes an insertion rod 2 for inserting into the filter tank. The material of the insertion rod 2 can be metal or plastic. According to the size and depth of the filter tank, the length of the insertion rod can be 10~500cm, and the diameter can be 1~10cm , the interior can be hollow or solid, but no matter which specification, the outer surface of the insertion rod 2 is provided with a scale line 1, and the zero scale line of the scale line starts from the bottom of the insertion rod.

[0031] The bottom of the insertion rod 2 is conical, and the conical bottom can reduce the resistance encountered by the insertion rod when it is inserted into the filter tank. The bottom of the insertion rod 2 is fixed with a sampling cylinder 5 through a fixed structure. In this embodiment, the fixed structure is a fixed ring 4. The fixed ring 4 has a certain width and flexibility, and the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com