Edible mushroom factory ground insulation structure

A technology of edible mushrooms and factories, applied to floors, building structures, insulation layers, etc., can solve the problems of low strength, large temperature changes, and low profits, and achieve good heat preservation effects, small temperature changes, and avoid cold bridges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

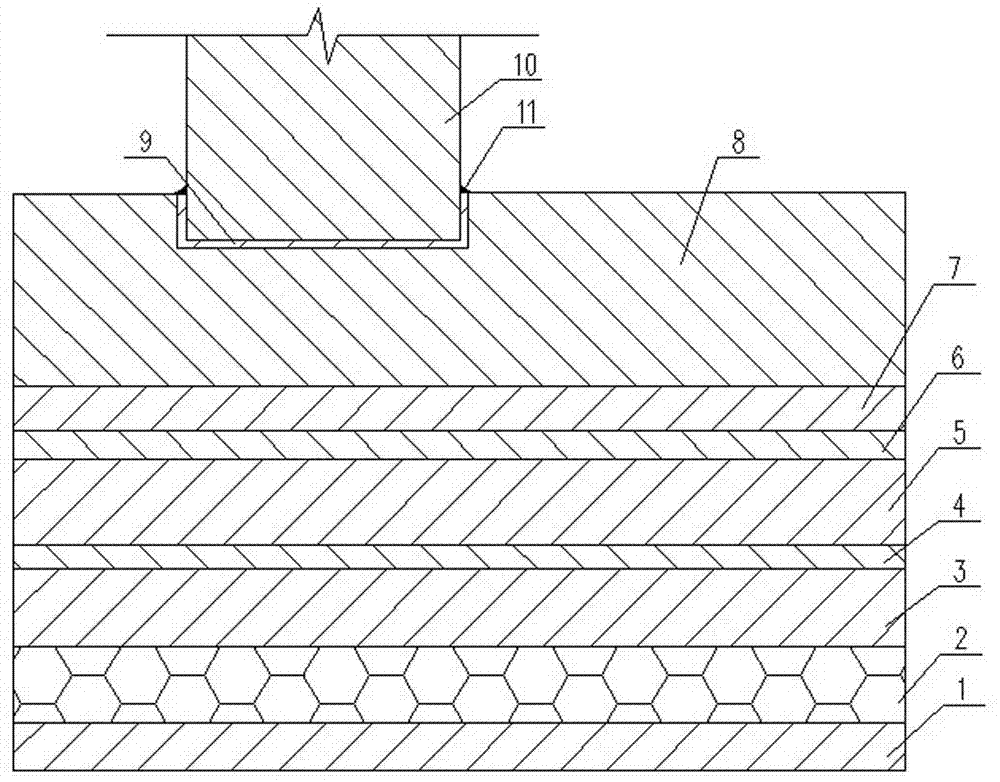

[0010] Such as figure 1 As shown, the ground insulation structure of the edible fungus factory includes: a crushed stone layer 2 arranged on the ground 1, a lower concrete layer 3 arranged on the crushed stone layer 2, a lower waterproof cloth layer 4 arranged on the lower concrete layer 3, and a The thermal insulation layer 5 on the lower waterproof cloth layer 4, in this embodiment, the thermal insulation layer 5 is a polyethylene extruded insulation board, the upper waterproof cloth layer 6 arranged on the thermal insulation layer 5 is arranged on the upper waterproof cloth layer The steel mesh layer 7 on the 6 and the upper concrete layer 8 arranged on the steel mesh layer 7 are provided with a U-shaped aluminum positioning groove 9 on the described upper concrete layer 8, and the lower end of the edible fungus fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com