Deepwater wet heat-insulation anode pipeline and method for manufacturing same

A wet-type, anode technology, applied in the direction of protecting pipelines through heat insulation, heat preservation, pipeline protection, etc., can solve the problems of complicated pipeline installation, broken anode wires, and scrapping of the whole pipe, and achieves simple production process, good heat preservation effect, and guaranteed sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

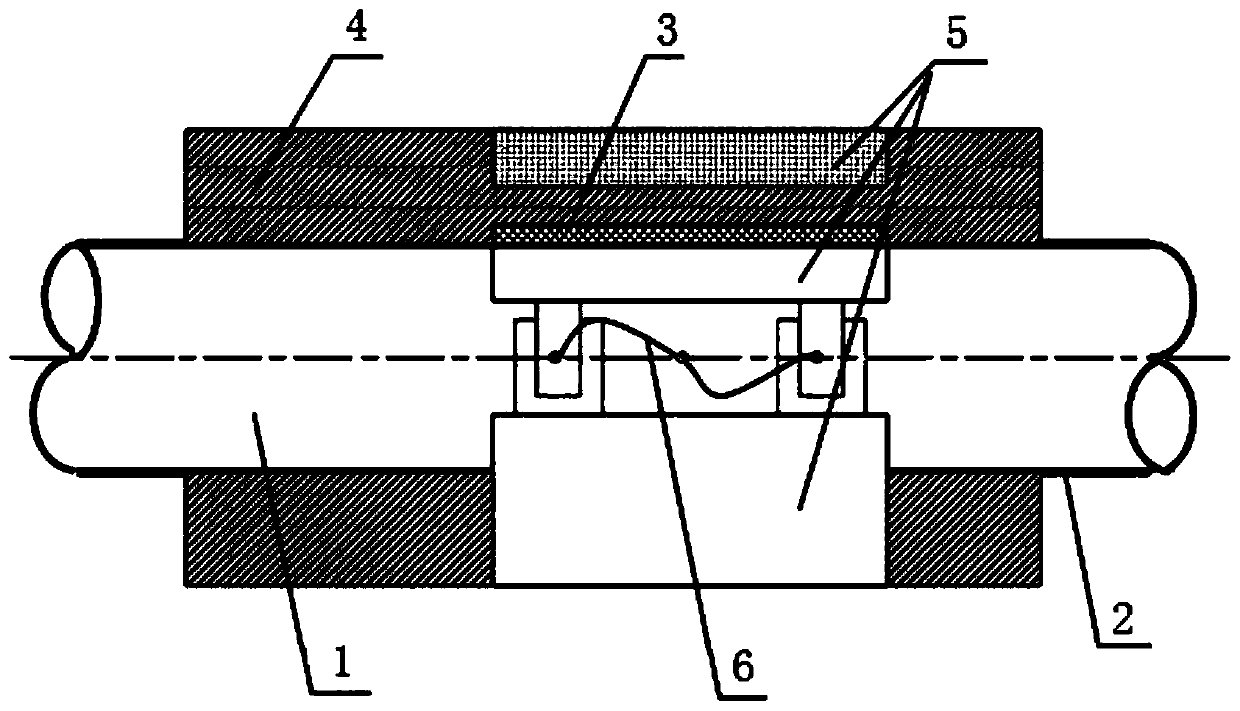

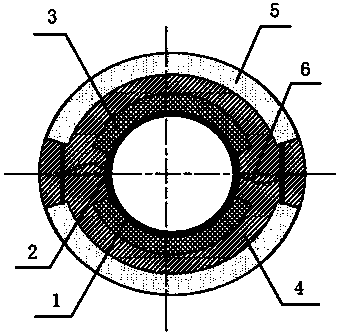

[0055] In this embodiment, the fused-bonded epoxy powder anticorrosion layer 2 is a powder material with a glass transition temperature of 110°C; the vacuum insulation layer 3 is a vacuum insulation panel with a thermal conductivity of 0.0025w / m.k; The density of the wet insulation layer 4 described above is 680kg / m 3 , the compressive strength is 8MPa, the applicable temperature can reach 105 ℃ composite polyurethane integral casting; The said bracelet type anode 5 is installed in the middle of the said wet insulation layer 4, and its outer surface is lower than the wet insulation layer 4 The outer surface is 3mm.

Embodiment 2

[0057] In this embodiment, the fused-bonded epoxy powder anticorrosion layer 2 is a powder material with a glass transition temperature of 130°C; the vacuum insulation layer 3 is a vacuum insulation panel with a thermal conductivity of 0.0021w / m.k; The density of the wet insulation layer 4 described above is 810kg / m 3 , the compressive strength is 25MPa, the applicable temperature can reach 125 ℃ composite polyurethane integral casting; The said bracelet-type anode 5 is installed in the middle of the said wet insulation layer 4, and its outer surface is lower than that of the wet insulation layer 4 The outer surface is 4mm.

Embodiment 3

[0059] In this embodiment, the fused-bonded epoxy powder anticorrosion layer 2 is a powder material with a glass transition temperature of 150°C; the vacuum insulation layer 3 is a vacuum insulation panel with a thermal conductivity of 0.0012w / m.k; The density of the wet insulation layer 4 described above is 890kg / m 3 , with a compressive strength of 35MPa and an applicable temperature of up to 145°C for integral casting of composite polyurethane; the bracelet-type anode 5 is installed in the middle of the wet-type insulation layer 4, and its outer surface is lower than that of the wet-type insulation layer 4 The outer surface is 5mm.

[0060] The deep-water wet-type thermal insulation anode pipeline of the present invention has a reasonable structure and is simple to manufacture. Since the anode wire is buried in the thermal insulation layer, there is no need to set an outer protective layer, a waterproof cap at the pipe end, and a concrete counterweight layer as in the prior...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com