Flow channel clamp

A fixture and runner technology, used in manufacturing tools, manipulators, program-controlled manipulators, etc., can solve the problems of difficulty, increased runner removal, and the lack of integration of sensors and fixture bodies, achieving compact size and large clamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

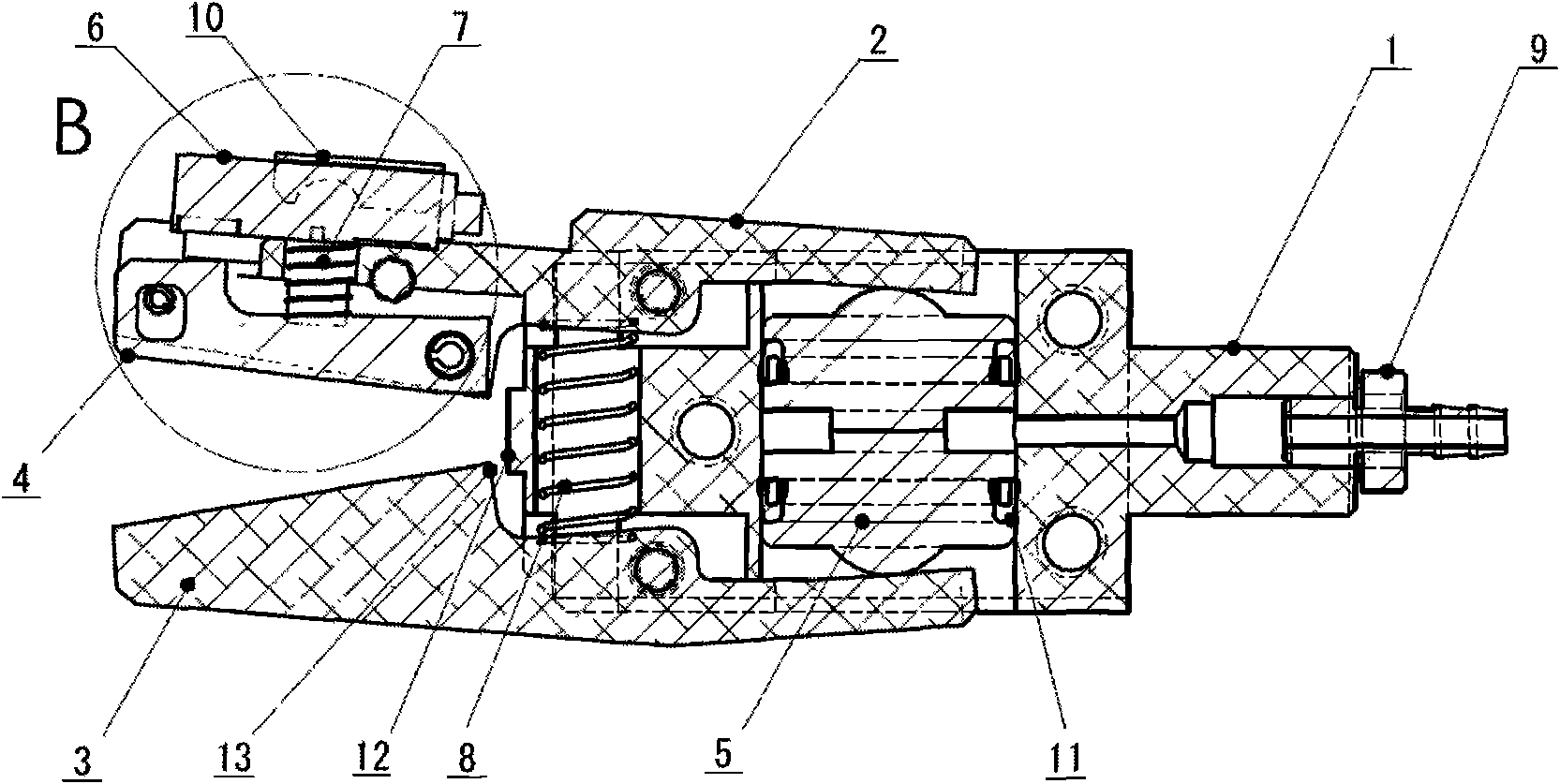

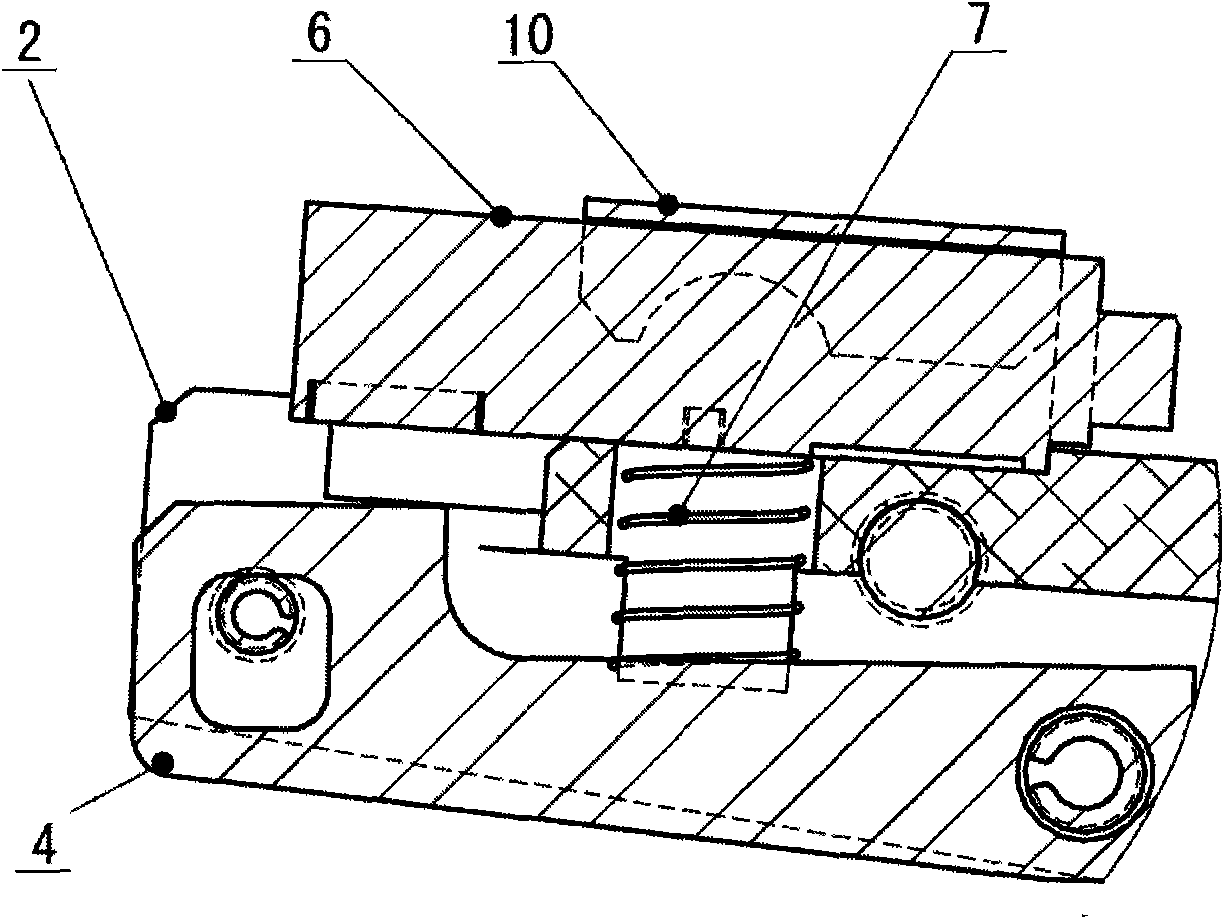

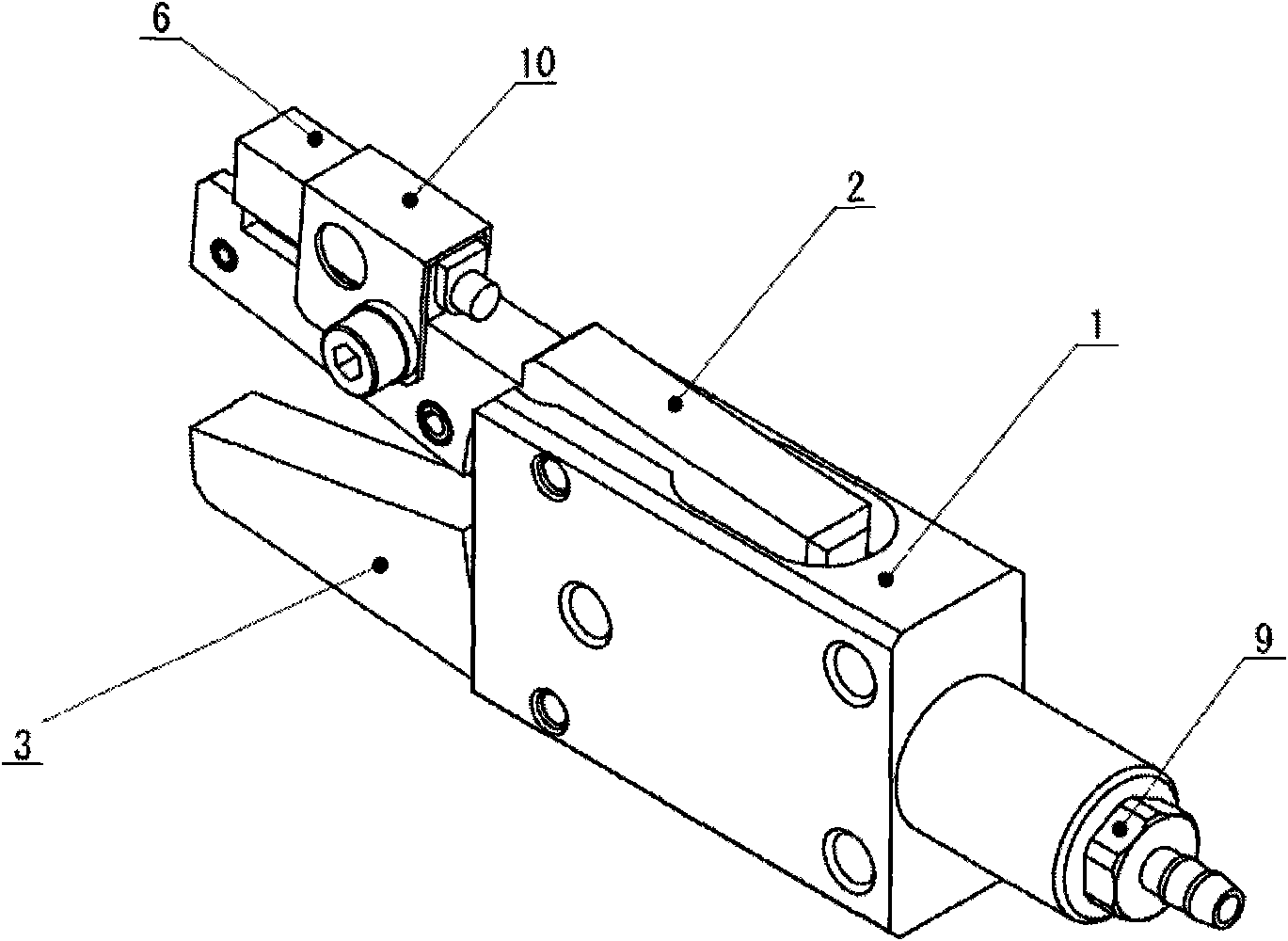

[0011] Such as figure 1 , figure 2 , image 3 As shown, the clamp base 1 adopts an external structure combining a cuboid and a cylinder, so that two connection methods of screw and clamping the cylinder can be used, and its small shape is guaranteed; the clamp claw 2 on the sensor side and the clamp claw 3 are respectively The revolving pin is connected with the fixture base 1, and the two fixture claws can rotate around the revolving pin. The two fixture claws are designed to be flat, and shavings are made on the clamping surface to facilitate various flow channels of the fixture; the sensor 6 is installed on the sensor side of the fixture claw 2 on the sensor fixing frame 10; two pistons 5 are arranged in the cavity of the fixture base 1, and the pistons are oblong in design, which increases the force-bearing area without increasing the thickness of the fixture to obtain greater clamping force , the arc surfaces of the two pistons 5 are in contact with the clamp claw 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com