Fibrilia wall cloth

A technology of hemp fiber non-woven fabric and hemp fiber, which is applied in the direction of non-woven fabrics, textiles and papermaking, and can solve the problem of environmental air pollution caused by aggravated wall coverings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

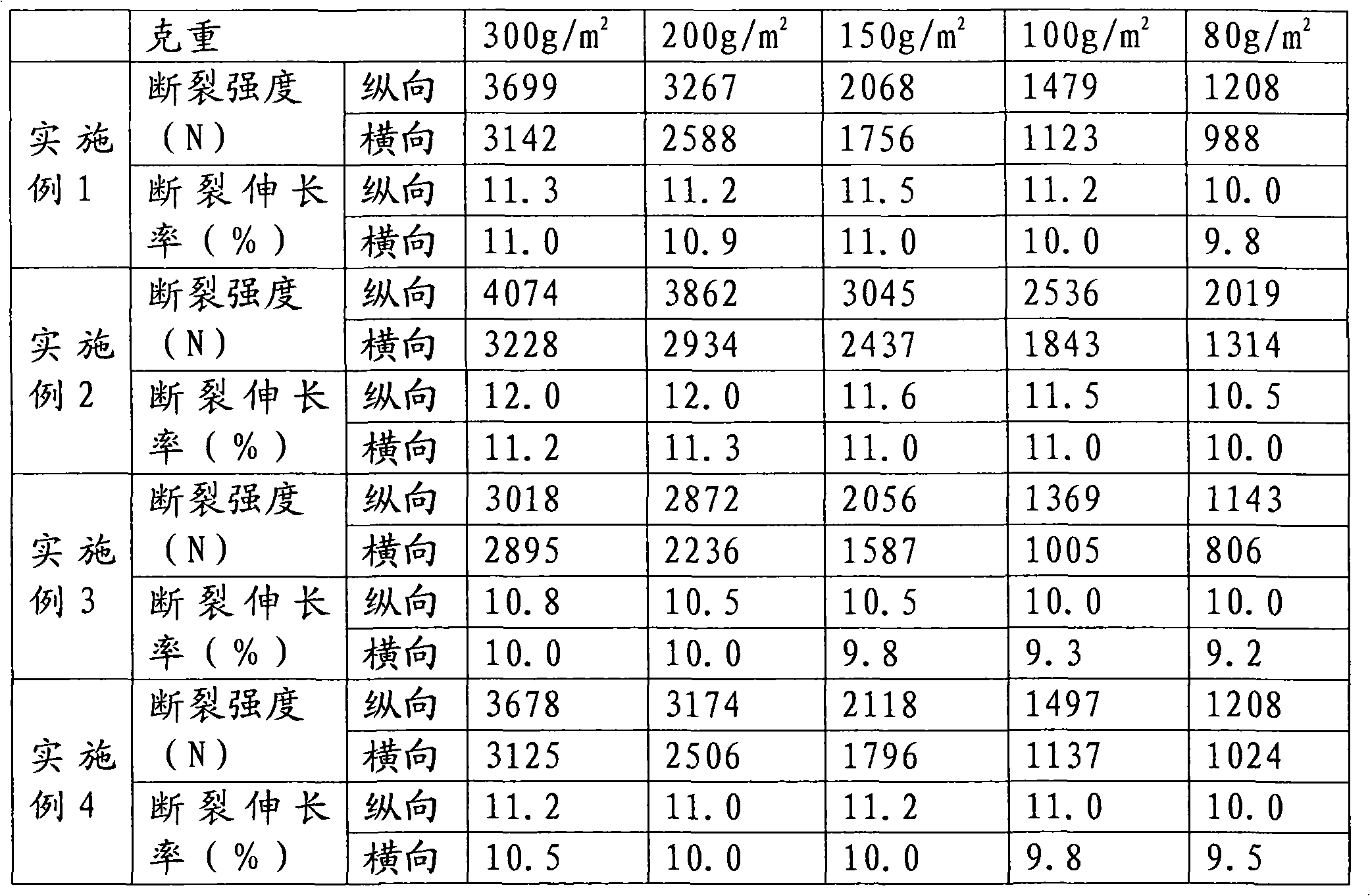

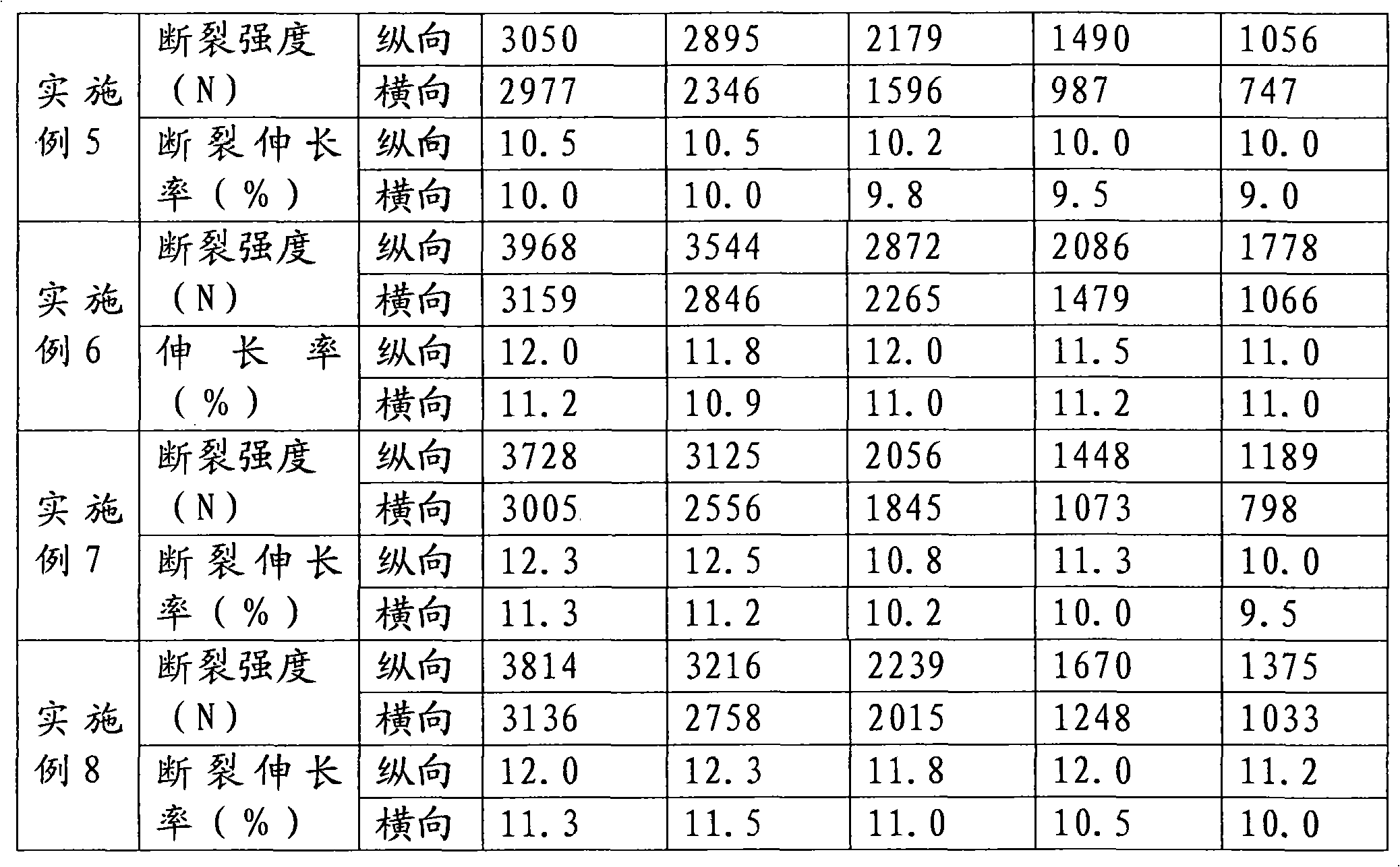

Embodiment 1

[0021] Get the flax fiber that is 30% by mass percentage, 30% bonding fiber low-melting point chemical fiber polypropylene fiber and 40% cotton fiber, flax fiber is opened once, above-mentioned bonding fiber and cotton fiber are opened twice, above-mentioned through The flax fiber after opening, the binding fiber and the cotton fiber are mixed; the above-mentioned mixed fiber is combed into a web by a carding machine, thereby forming a fiber web of the above-mentioned mixed fiber.

[0022] The fiber web obtained above is subjected to one, two or three times of needling through a needling machine, and the needling is 12,500 punches / m2; On the machine, the hot roll is used to hot-roll the fiber web to produce hemp fiber wall covering with good hand feeling.

Embodiment 2

[0024] Take 50% flax fiber by mass percentage, 40% bonding fiber low-melting point chemical fiber polypropylene fiber and 10% polyester fiber, carry out dyeing treatment to the above-mentioned fibers, then open the flax fiber after dyeing once, and the above-mentioned dyed The final bonded fibers and polyester fibers are opened three times, and the above-mentioned flax fibers, bonded fibers and polyester fibers after opening are mixed; the above-mentioned mixed fibers are disorderly formed into a net by air flow, thereby forming the fibers of the above-mentioned mixed fibers net.

[0025] The fiber web obtained above is subjected to four passes of needling through a needling machine, and the needling is 13,500 pricks / m2; The hot roll is used to hot-roll the fiber web to produce high-quality hemp fiber wall covering with good hand feeling.

Embodiment 3

[0027] Get the jute fiber that mass percent is 65%, 15% bonding fiber low melting point composite fiber (ES) and the viscose fiber of 20%, the jute fiber is opened once (after testing, the average length of hemp fiber reduces 36%) , opening four times to the above-mentioned bonding fiber and viscose fiber, mixing the above-mentioned jute fiber, bonding fiber and viscose fiber after opening; carding the above-mentioned mixed fiber into a net through a carding machine, thereby forming A fiber web of the aforementioned mixed fibers.

[0028] The fiber web obtained above is subjected to seven passes of needling through a needling machine, and the needling is 14,500 punches / meter square; The rollers are hot-rolled to form the fiber web, so as to produce high-quality hemp fiber wall covering with good hand feeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com