Movable type hydraulic trash-cleaning machine

A cleaning machine and mobile technology, which is applied in the field of cleaning machines, can solve the problem of large differences in mechanical properties such as diameter, rigidity, toughness and curvature radius, complex structure of underwater cleaning mechanism, loose oil pipes, and insufficient tension. First-class problems, to achieve the effects of saving production costs, safe use, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawings and embodiments.

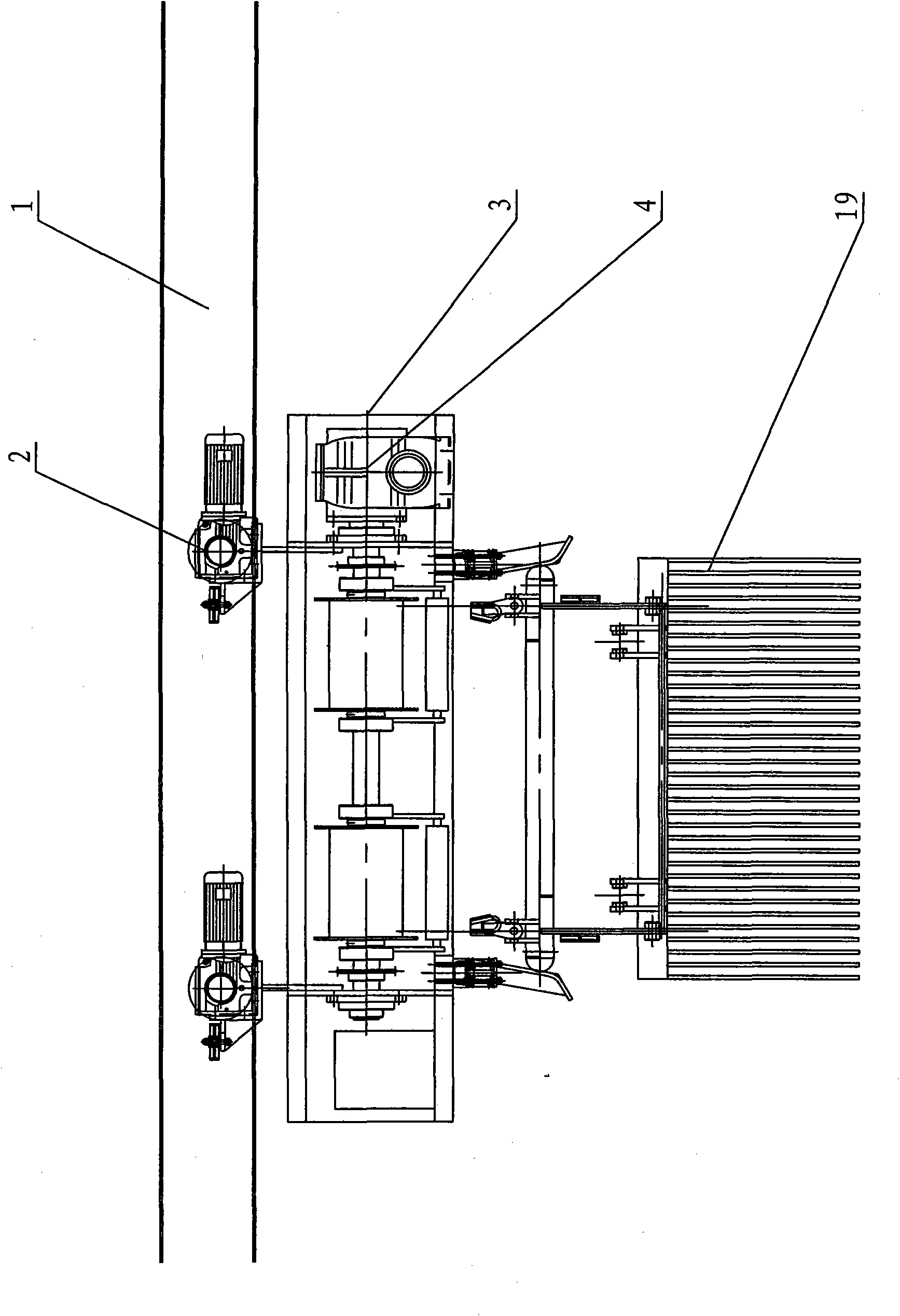

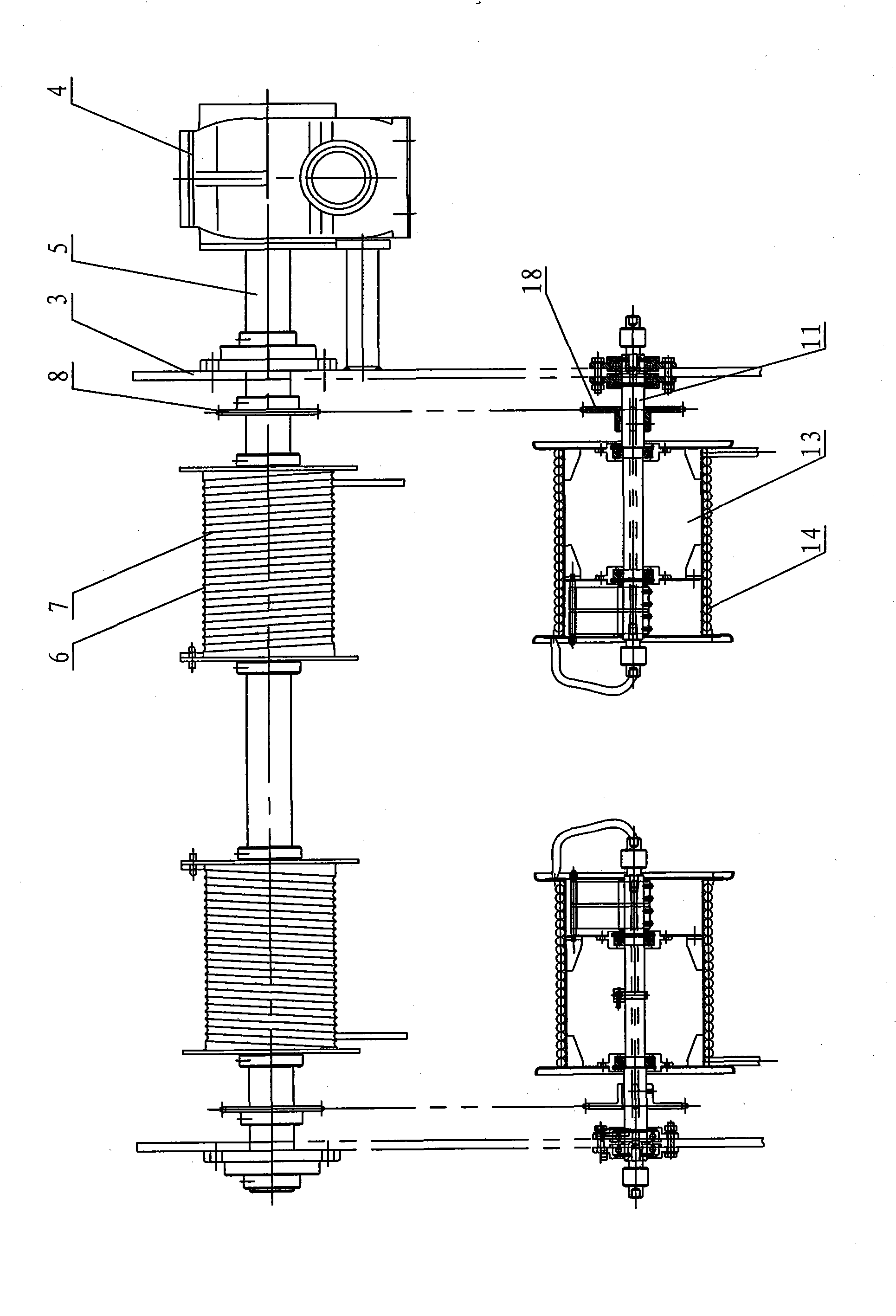

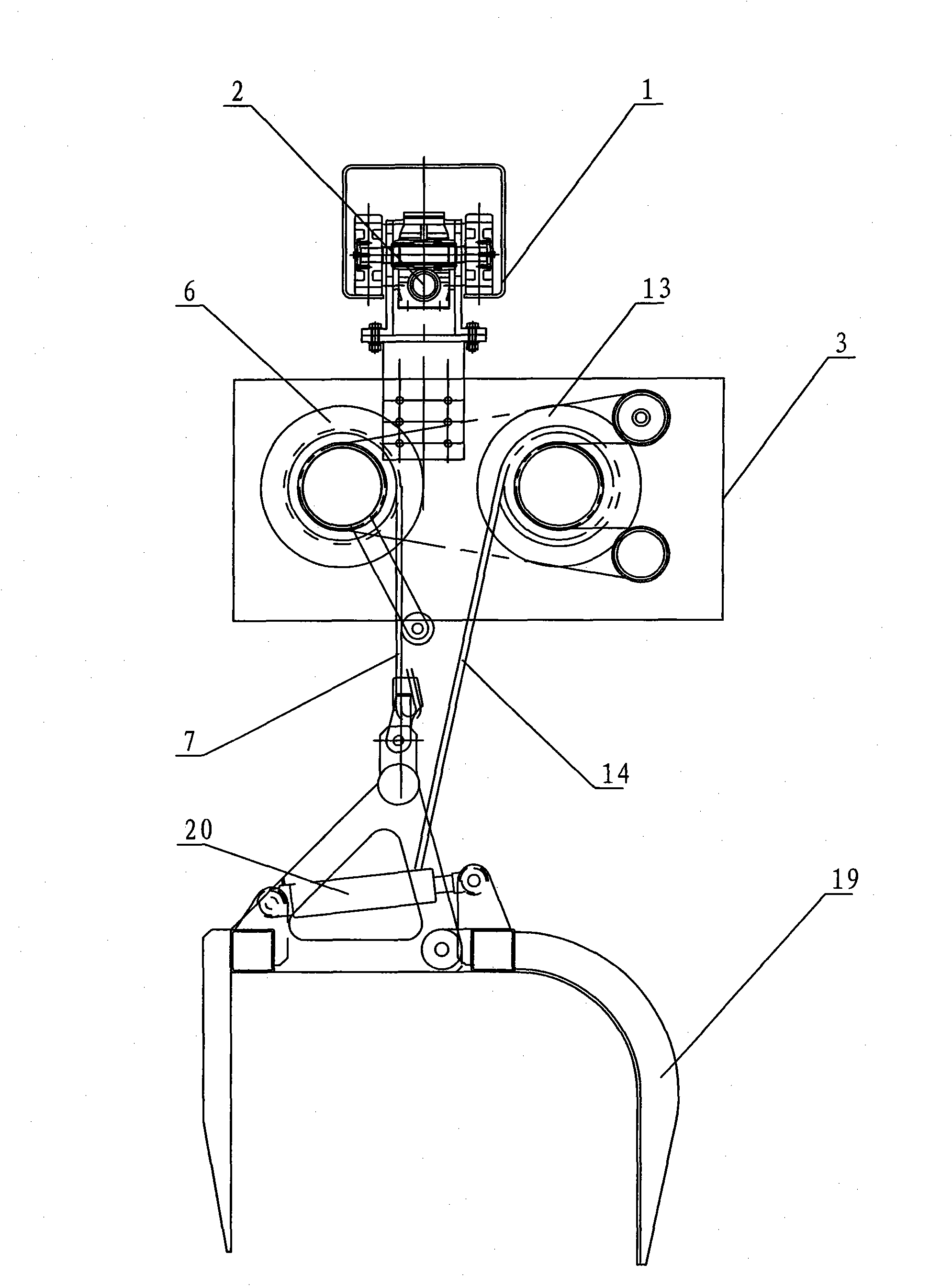

[0019] Figure 1-4 The mobile hydraulic cleaning machine shown mainly includes track 1, two travel motors 2, frame 3, drive motor 4, drive shaft 5, two wire rope reels 6, wire rope 7, two drive sprockets 8, Onboard hydraulic pump station 9, oil inlet rotary joint 10, driven shaft 11, two oil pipe reels 13, oil pipe 14, spring seat 15, mainspring spring 16, compensation rotary joint 17, two driven sprockets 18, Slag removal rake bucket 19, hydraulic oil cylinder 20, pin shaft 21. Two walking motors 2 are installed in the track 1 and walk in the track 1. The lower end of the walking motor 2 is connected to the frame 3; Two drive sprockets 8 and two wire rope drums 6 are symmetrically installed on the drive shaft 5 inside, and the wire rope 7 is wound on the wire rope drum 6; Two driven sprockets 18 and two oil pipe reels 13 are symmetrically installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com