Tension pulley assembly with hook-bolt structure

A tensioner and assembly technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of large size, poor maneuverability, complicated installation process, etc., to reduce the volume and shorten the effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

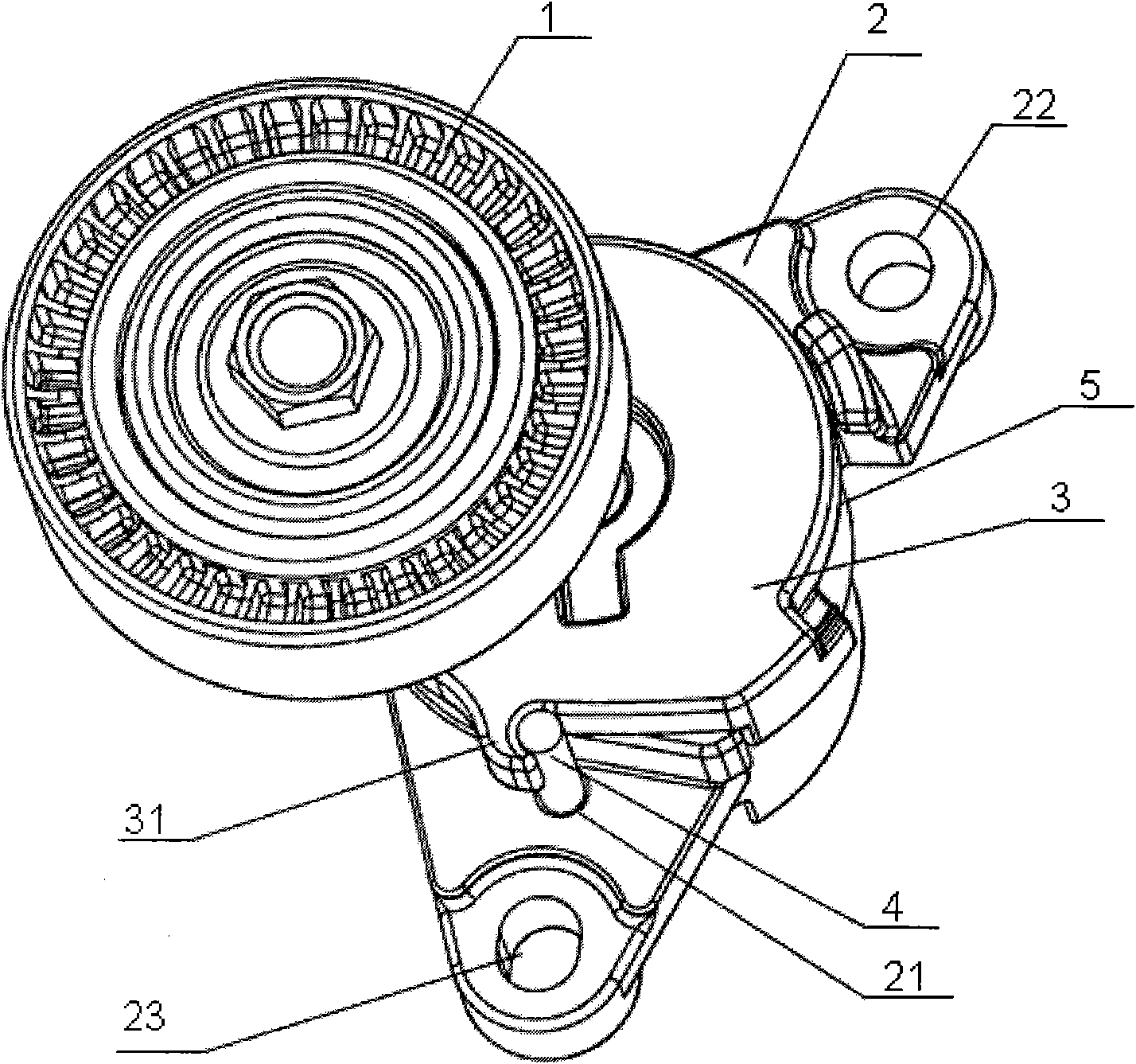

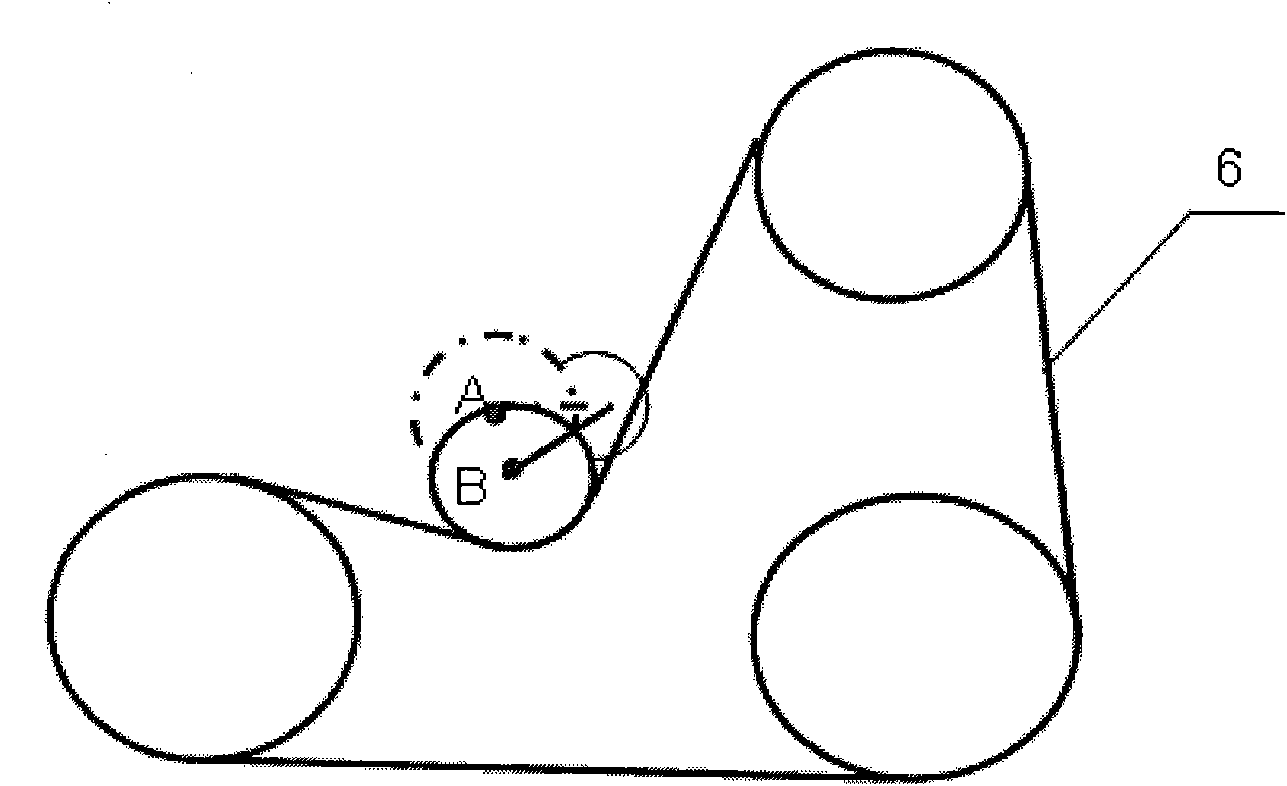

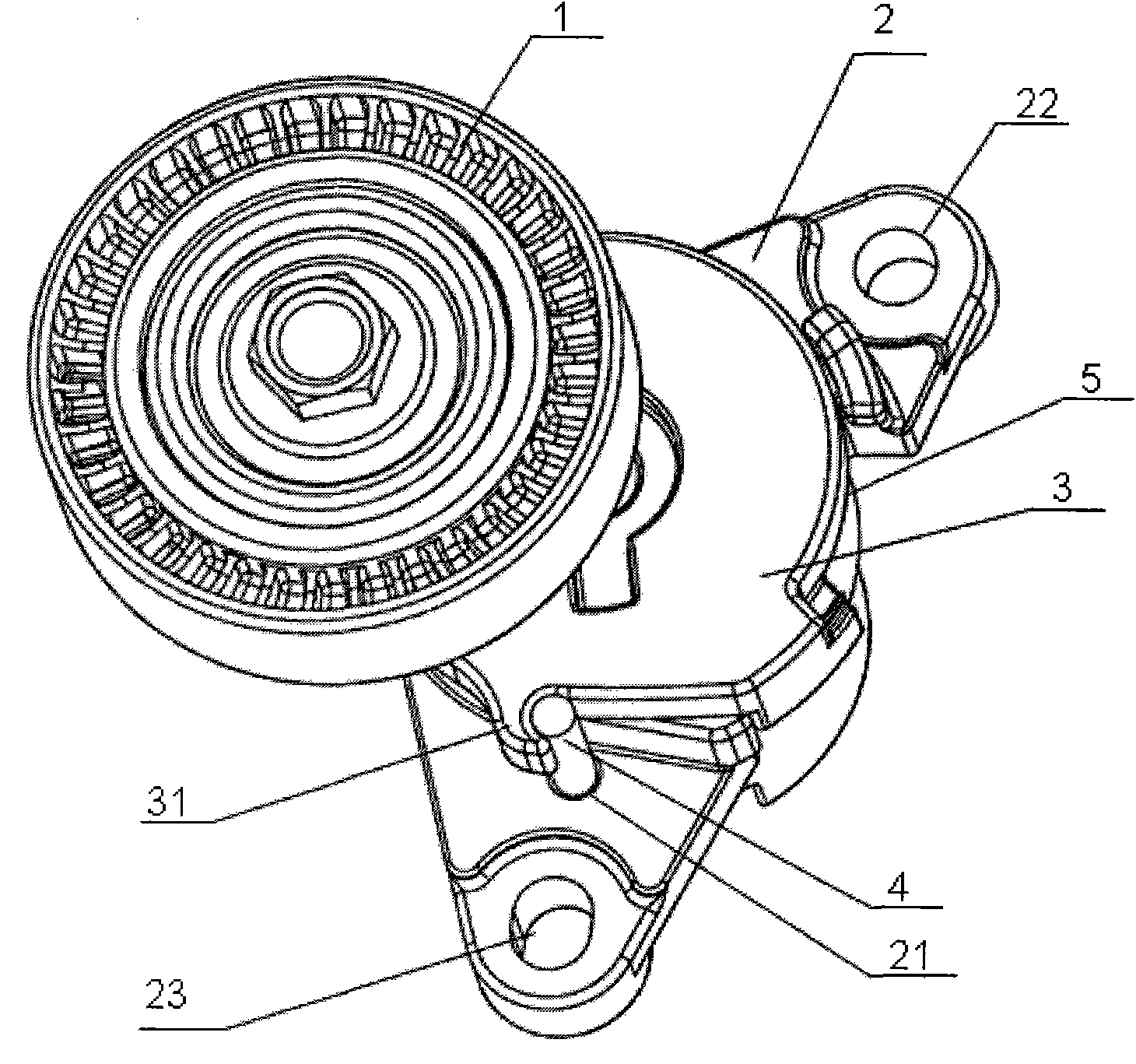

[0013] In order to reduce the external dimension of the tensioning wheel assembly and facilitate the installation of the wheel train belt, the present invention designs a latch structure in the form of a hook on the tensioning arm. The specific implementation is: the tensioning wheel assembly is composed of a pulley 1, a mounting base 2, a tensioning arm 3 and a latch 4, wherein the installation structure of the pulley 1, the mounting base 2, and the tensioning arm 3 is the same as that of the present The technology is the same, there are mounting holes 22, 23 at the two ends of the mounting base 2, which are used to install the assembly on the engine. The improvement of the present invention is that a bolt hole 21 is designed on the installation base 2, and a bolt hook 31 is designed on the tension arm, and a torsion spring 5 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com