Fin type evaporator and refrigerator thereof

A finned evaporator and evaporator technology, applied in evaporators/condensers, defrosting, household appliances, etc., can solve the problems of insufficient support, poor defrosting of heaters, large thermal resistance, etc., to avoid loosening Or falling off, shortening the defrosting time, reducing the effect of heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

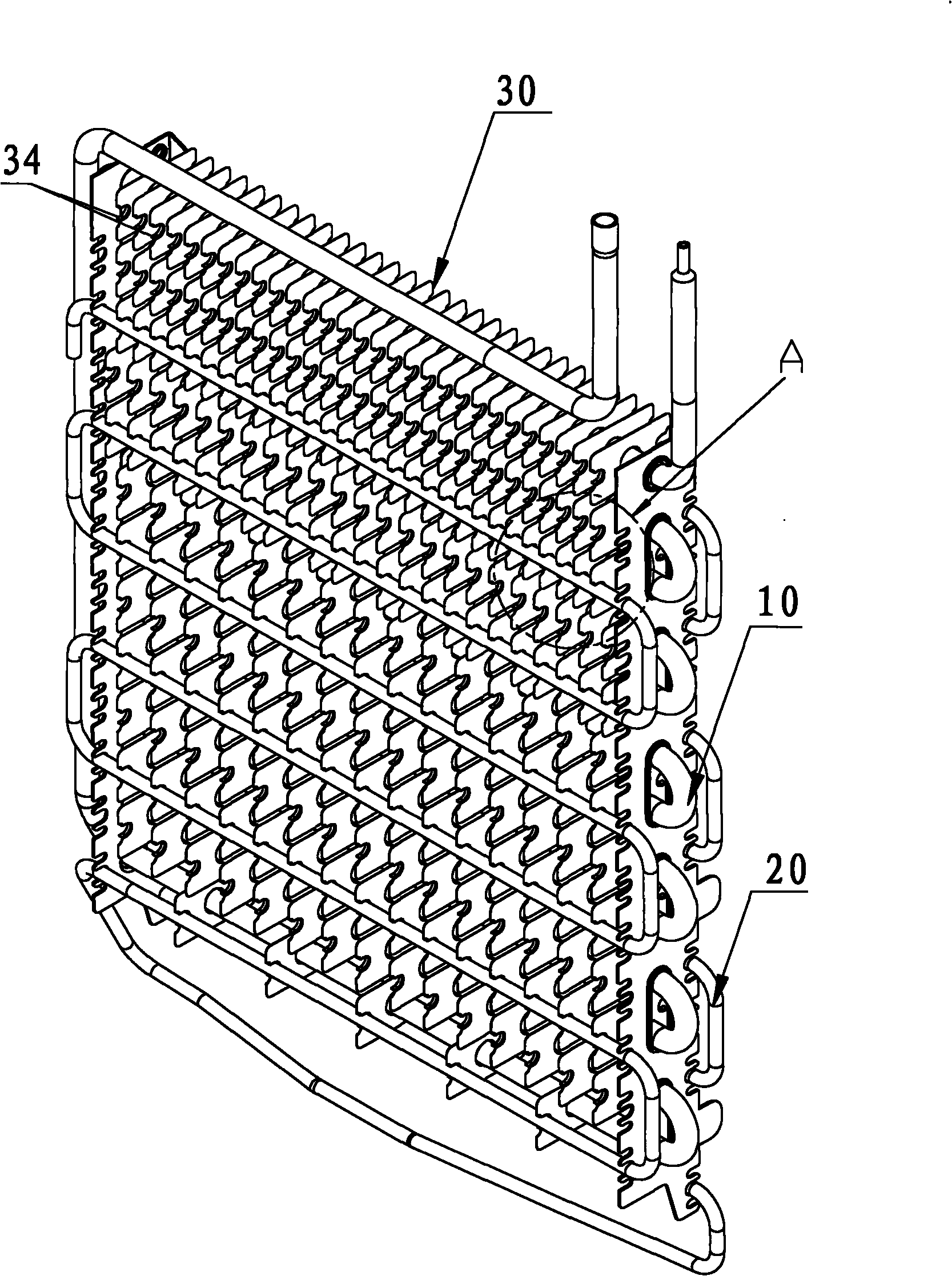

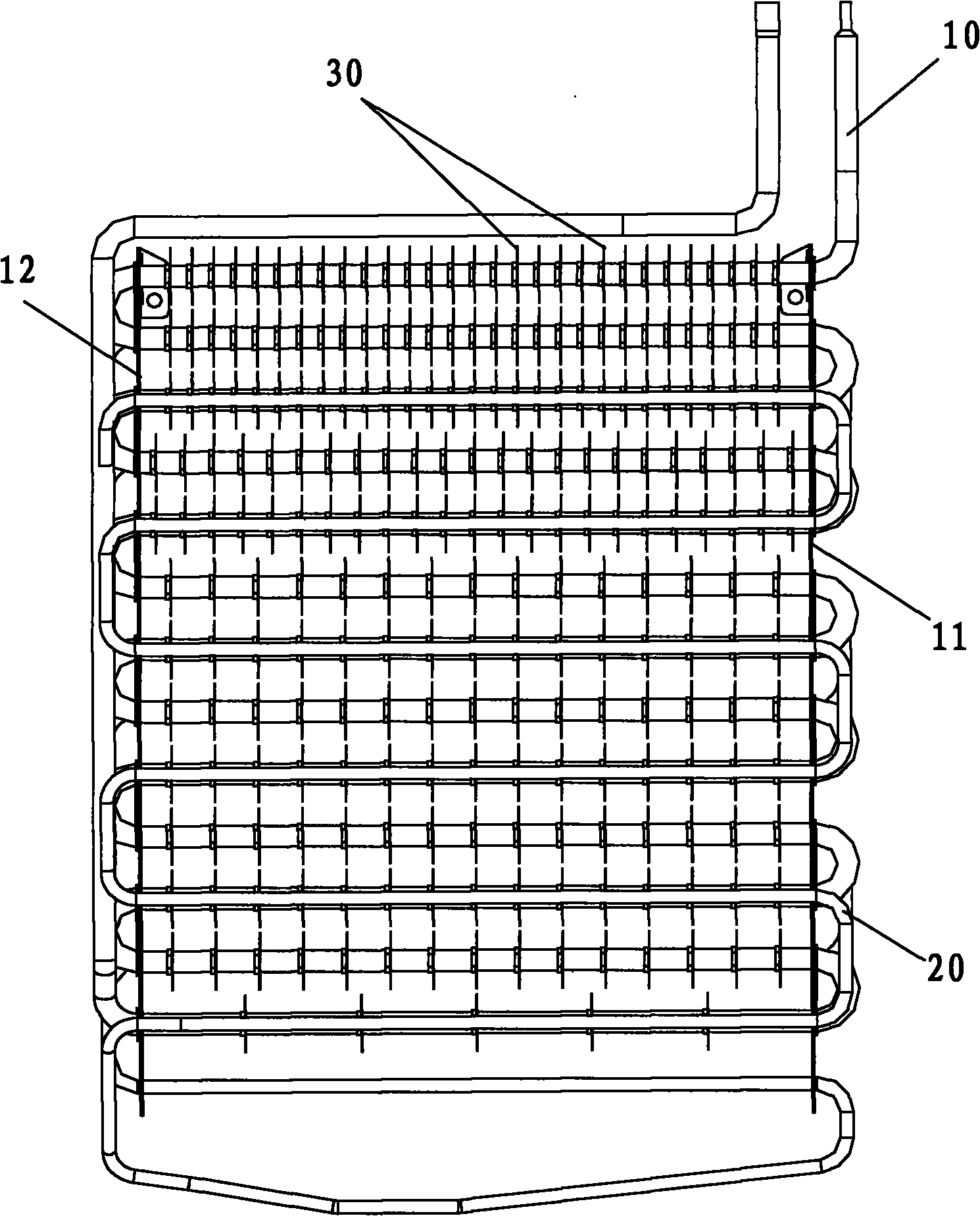

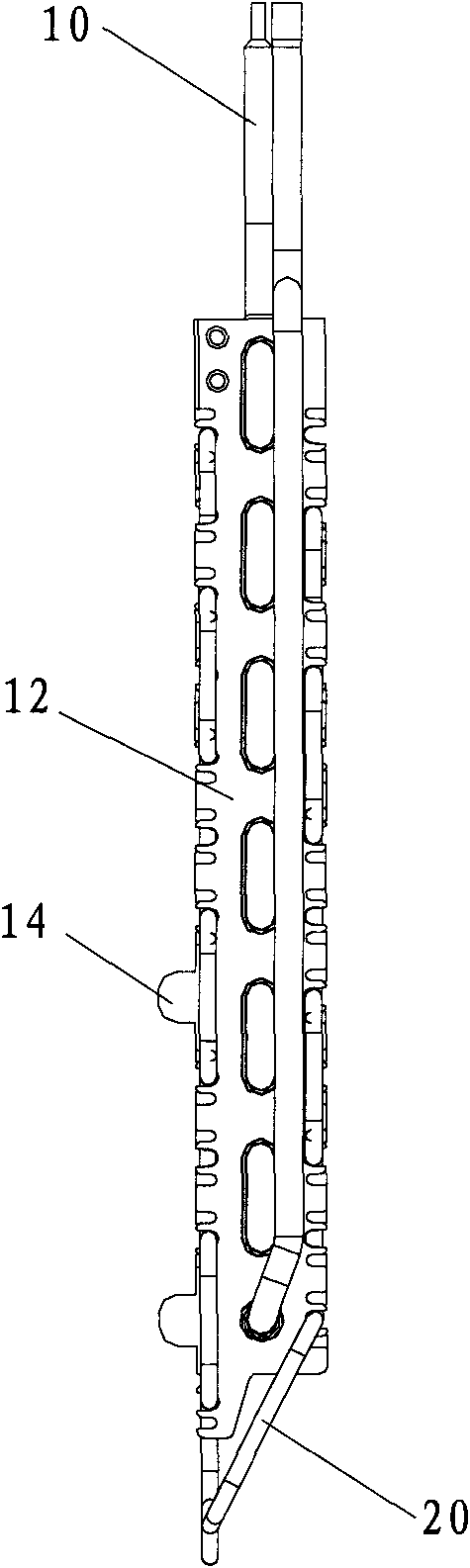

[0035] This embodiment relates to a refrigerator with a novel evaporator, which includes a refrigerator compartment, a freezer compartment and a refrigeration system for the refrigerator. The refrigeration system of the refrigerator includes a compressor for generating cycle power, an evaporator for heat exchange, a capillary tube for expansion, a condenser and a refrigerant flowing in gas-liquid conversion in the piping system. The evaporator is generally installed on the back of the refrigerator. The sensor senses the temperature change of the freezer compartment. When the temperature is lower than the set value, the refrigeration system is activated to cool down. Please refer to figure 1 The evaporator used for heat exchange is the main component of refrigeration, including single or multiple rows of refrigerant coils 10 and several fins 30 sleeved on the refrigerant coils 10 . A groove for installing a heater tube for defrosting is provided on each fin 30 . In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com