High-precision cable tension force test method based on model analysis

A technology of modal analysis and test method, applied in the direction of tension measurement, etc., can solve the problems of stiffness and vibration frequency, change, and unreliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

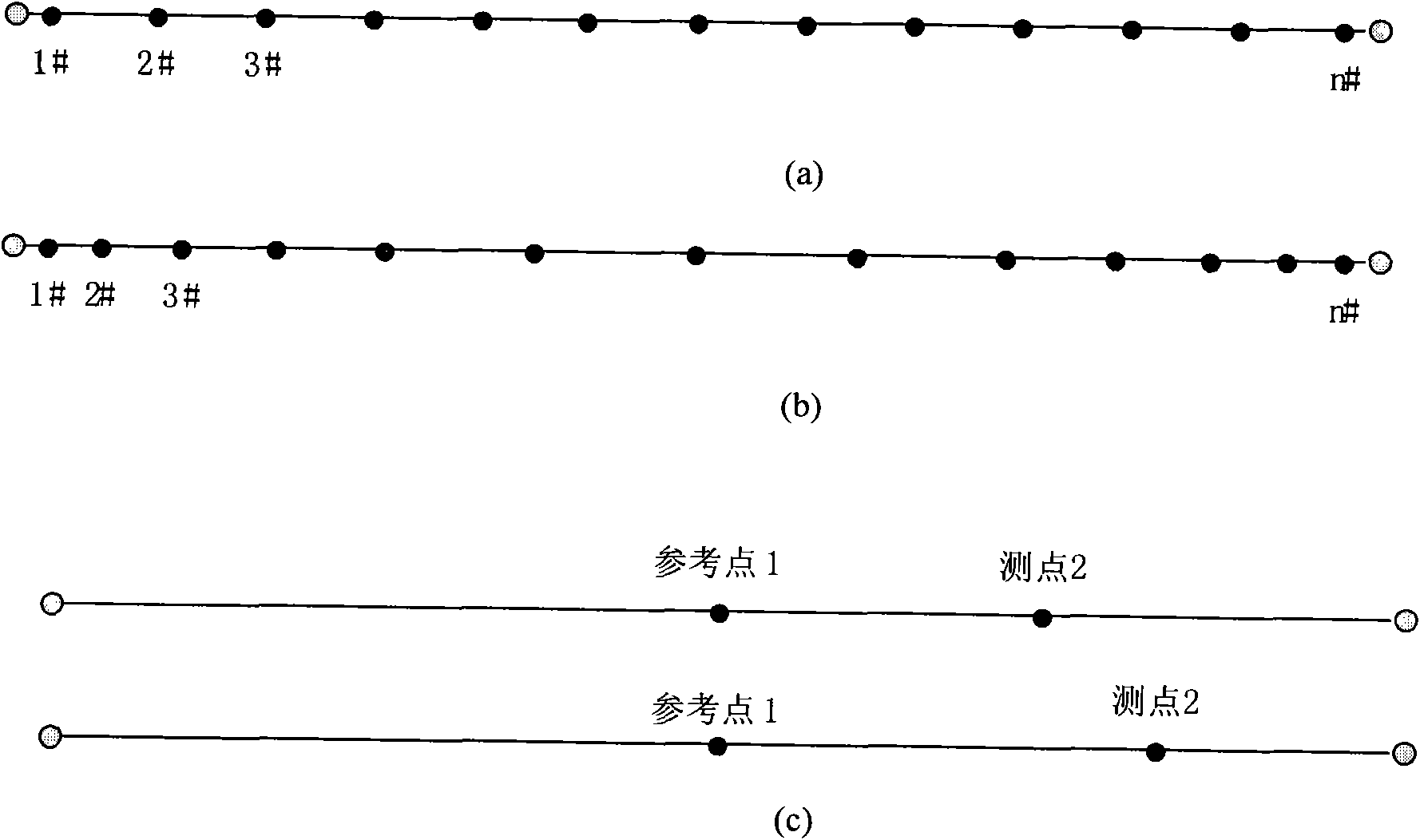

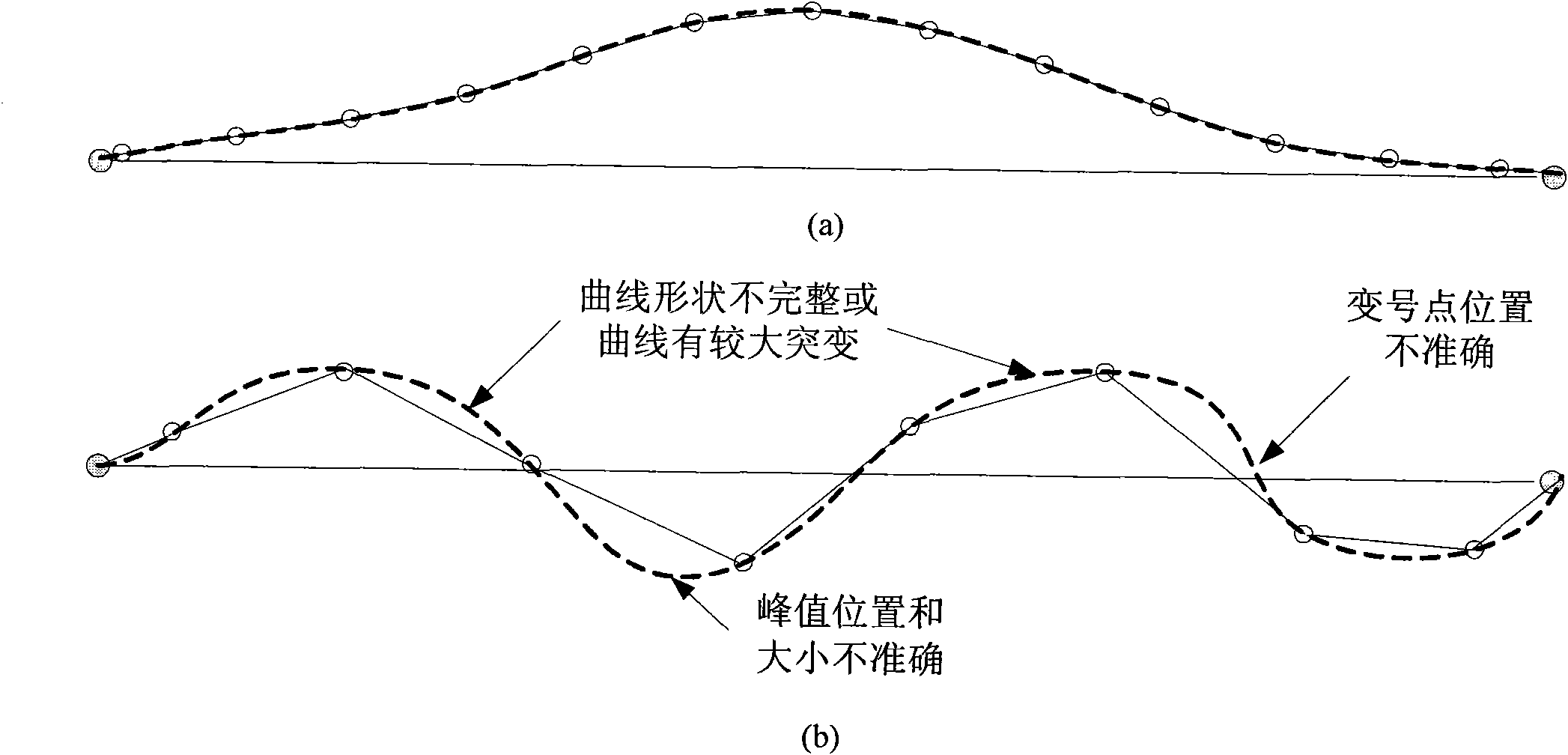

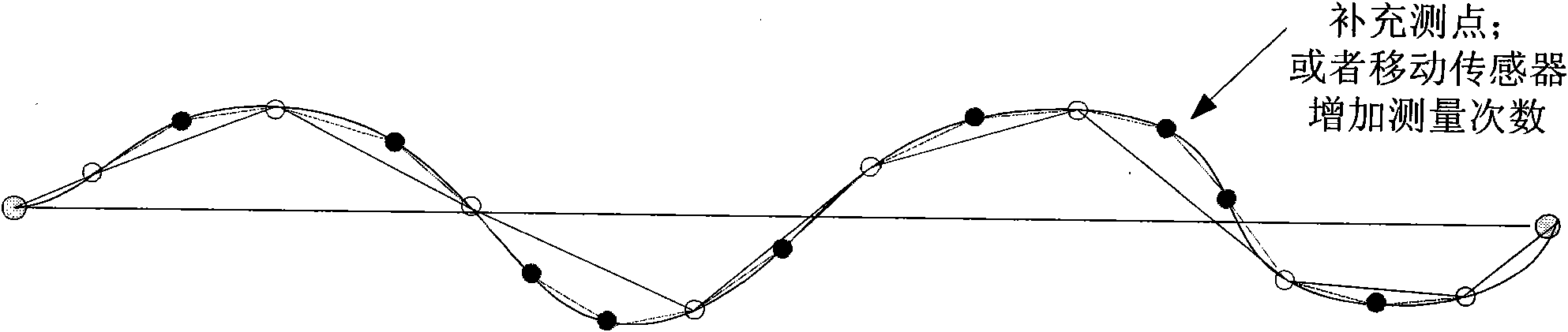

[0050] Firstly, data related to tensioned cables are collected on site, and two or more acceleration sensors are fixed on the cables along the surface of the cables. When the number of sensors is large, the modal information of the cable can be obtained through one measurement, and the sensors can be arranged at equal intervals (such as figure 1 (a)), you can also choose unequal spacing arrangement (such as figure 1 (b)), the principle of unequal spacing arrangement is that the spacing near the end of the cable is denser, and the spacing near the midpoint of the cable is relatively sparse. When fewer sensors are used, such as using only two acceleration sensors, the modal information of the cable can be obtained through multiple measurements. The specific method is to keep the position of one sensor unchanged, which is called the reference sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com