Light-emitting diode (LED) display panel and driving method thereof

A driving method and technology for display panels, applied in static indicators, instruments, etc., can solve problems such as poor display uniformity and inconsistent brightness, and achieve the effects of reducing driving current, consistent discharge power, and reducing driving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

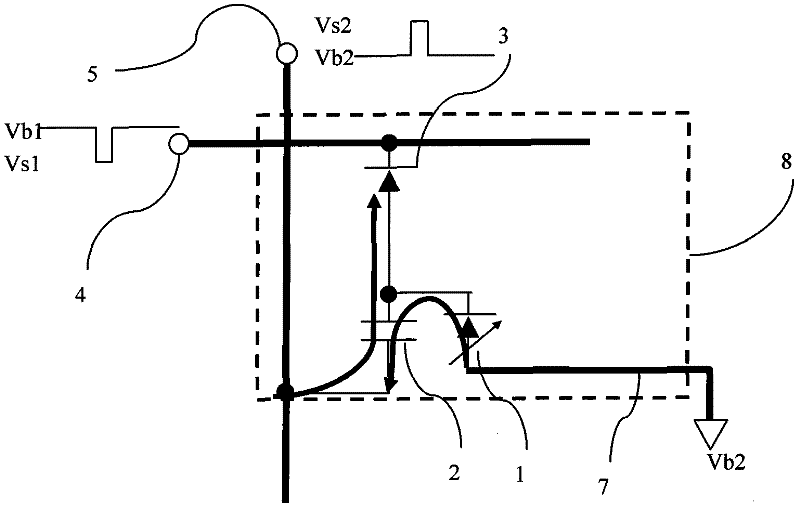

[0029] as attached figure 1 A LED display panel shown, each pixel 8 includes a first electrode 4, a display capacitor 2 connected to the first electrode 4, a diode 3 connected to the display capacitor 2 and a light emitting diode 1, and a display capacitor connected to the diode 3 The second electrode 5 is composed of the third electrode 7 connected to the other end of the light-emitting diode 1; the one-way charging circuit is composed of the diode 3 and the display capacitor 2, and the discharge display circuit is composed of the display capacitor 2 and the light-emitting diode 1. Relative to the display capacitor 2. The polarity of diode 3 and light-emitting diode 1 is opposite, as attached figure 1 As shown, it is also possible to change the polarity of the diode 3 and the light-emitting diode 1 at the same time.

Embodiment 2

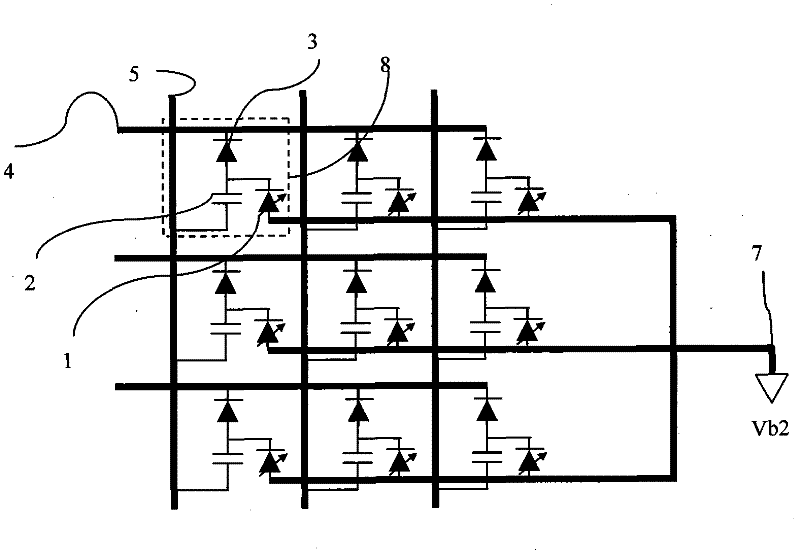

[0031] as attached figure 2 A LED display panel shown, each pixel 8 includes a first electrode 4, a display capacitor 2 connected to the first electrode 4, a diode 3 connected to the display capacitor 2 and a light emitting diode 1, and a display capacitor connected to the diode 3 Composition of the second electrode 5 is characterized in that the other ends of the light emitting diodes 1 of all pixels are connected together and connected with the third electrode 7; with respect to the display capacitor 2, the polarity of the diode 3 and the light emitting diode 1 is opposite, and can be as attached figure 2 As shown, the polarity of diode (3) and LED 1 can also be changed at the same time.

Embodiment 3

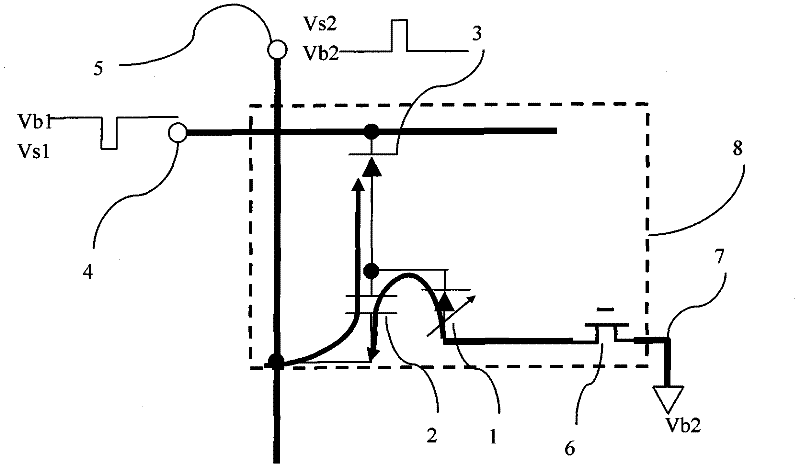

[0033] as attached image 3 A LED display panel shown, each pixel 8 includes a first electrode 4, a display capacitor 2 connected to the first electrode 4, a diode 3 connected to the display capacitor 2 and a light emitting diode 1, and a display capacitor connected to the diode 3 The second electrode 5, the switch tube 6 connected to the other end of the light-emitting diode 1, and the third electrode 7 connected to the switch tube 6 are composed; the diode 3 and the display capacitor 2 form a unidirectional charging circuit, and the display capacitor 2, the light-emitting diode 1 and the display switch 6 form a discharge display circuit. Compared with the display capacitor 2, the polarity of the diode 3 and the light-emitting diode 1 are opposite, which can be as attached image 3 As shown, it is also possible to change the polarity of the diode 3 and the light-emitting diode 1 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com