Device for transposing inner boxes as irradiation containers for irradiation device and operation method thereof

An irradiation container and irradiation device technology, which is applied in the irradiation container inner box transposition device of the irradiation device and its operating field, which can solve the problem of dose waste, higher requirements for absorbed dose unevenness, irradiated products, high unevenness, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

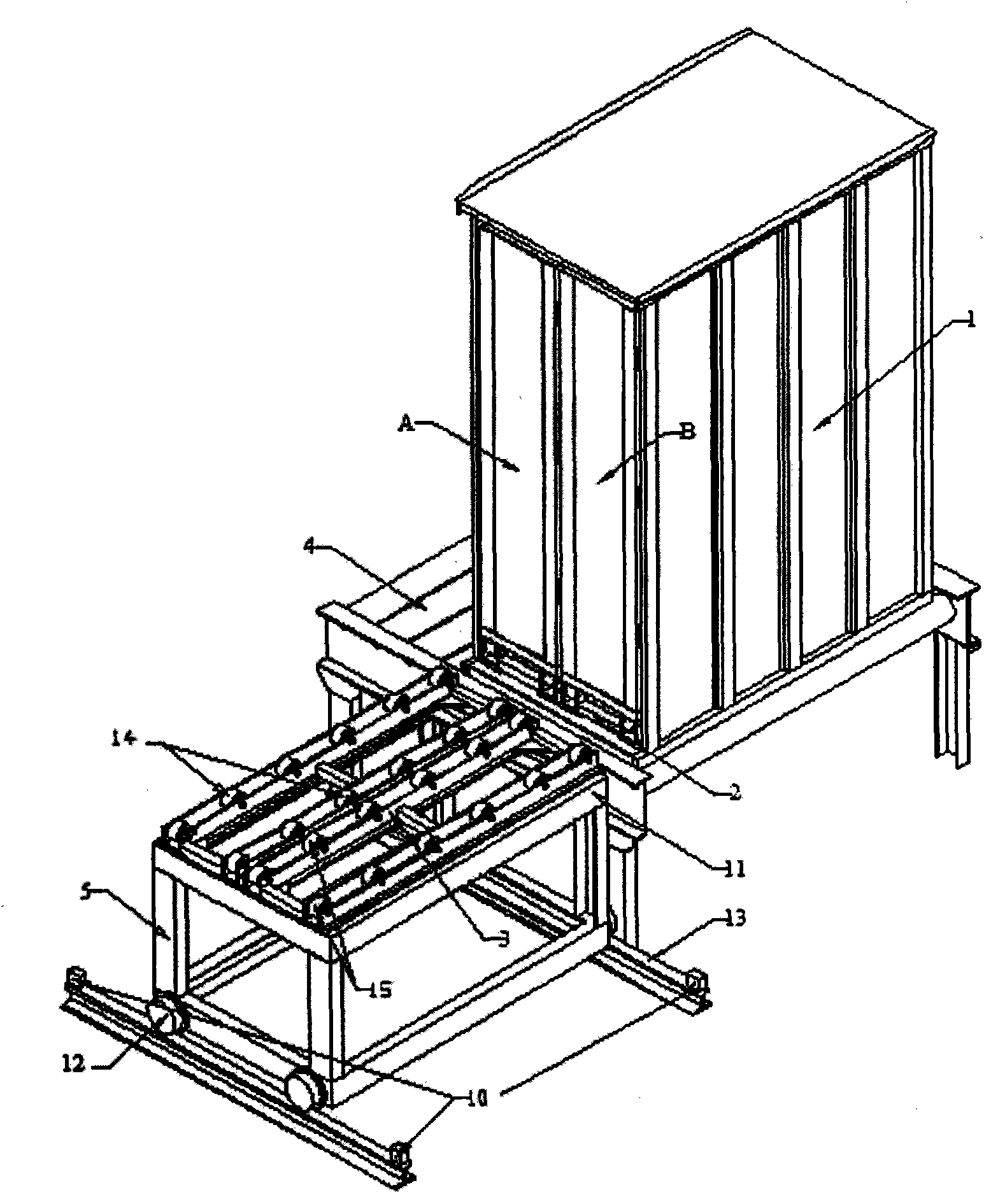

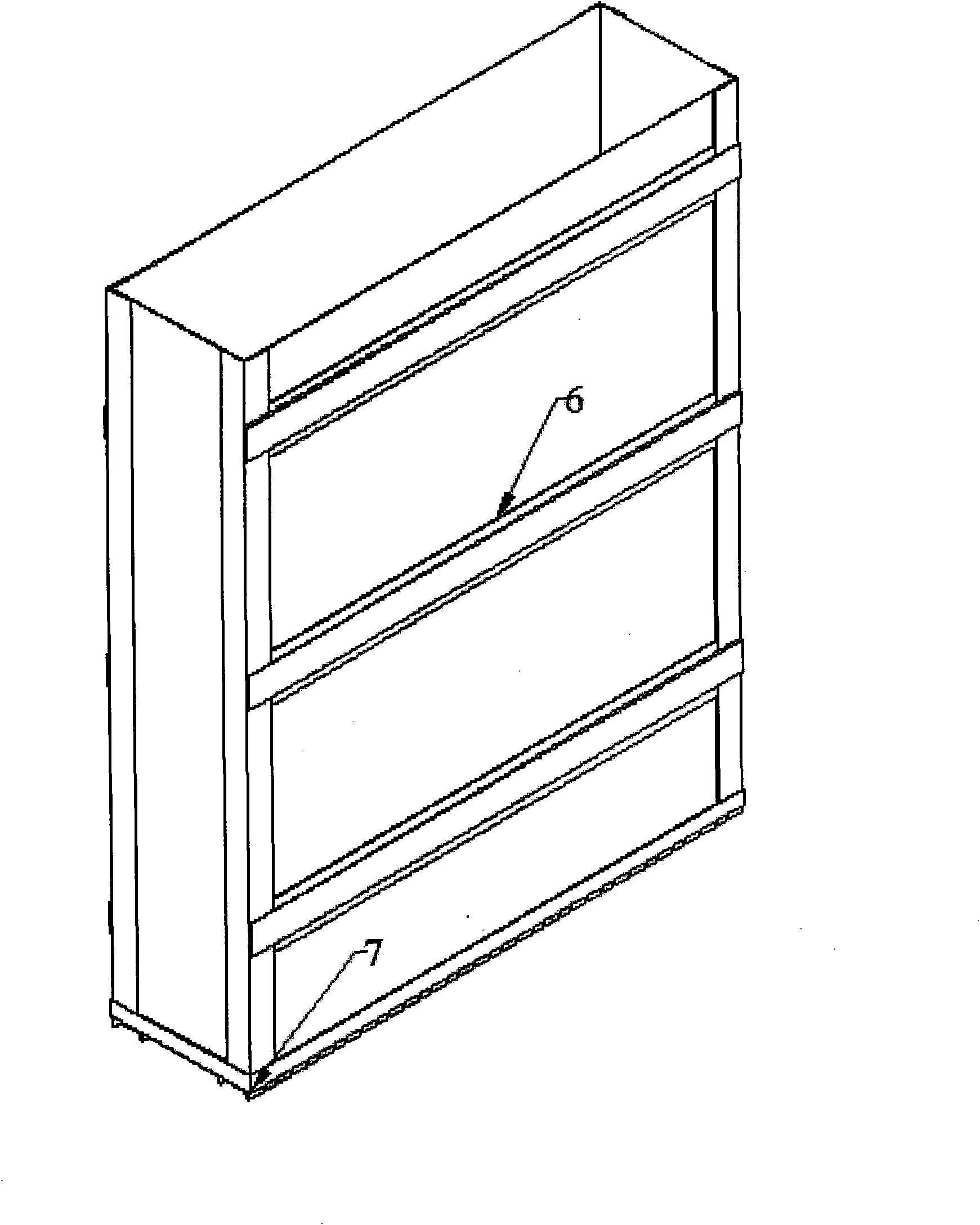

[0023] figure 1 Shown is the irradiation container inner box transposition device of the irradiation device of the present invention, including irradiation box 1, inner box A, inner box B, box inner support 2, box outer support 3, conveying device 4 and rail travel device 5, the irradiation box 1 is located on the conveying device 4, the inner box A and the inner box B are arranged in sequence on the box inner bracket 2 on the bottom surface of the irradiation box 1, and the box outer bracket 3 is located on the track moving device 5, and can move along the arrangement direction of the inner boxes A and B on the bottom surface of the irradiation box 1, and the inner boxes A and B can be supported on the inner support 2 and The box outer bracket 3 is vertically slid in the direction in which the inner boxes A and B are arranged.

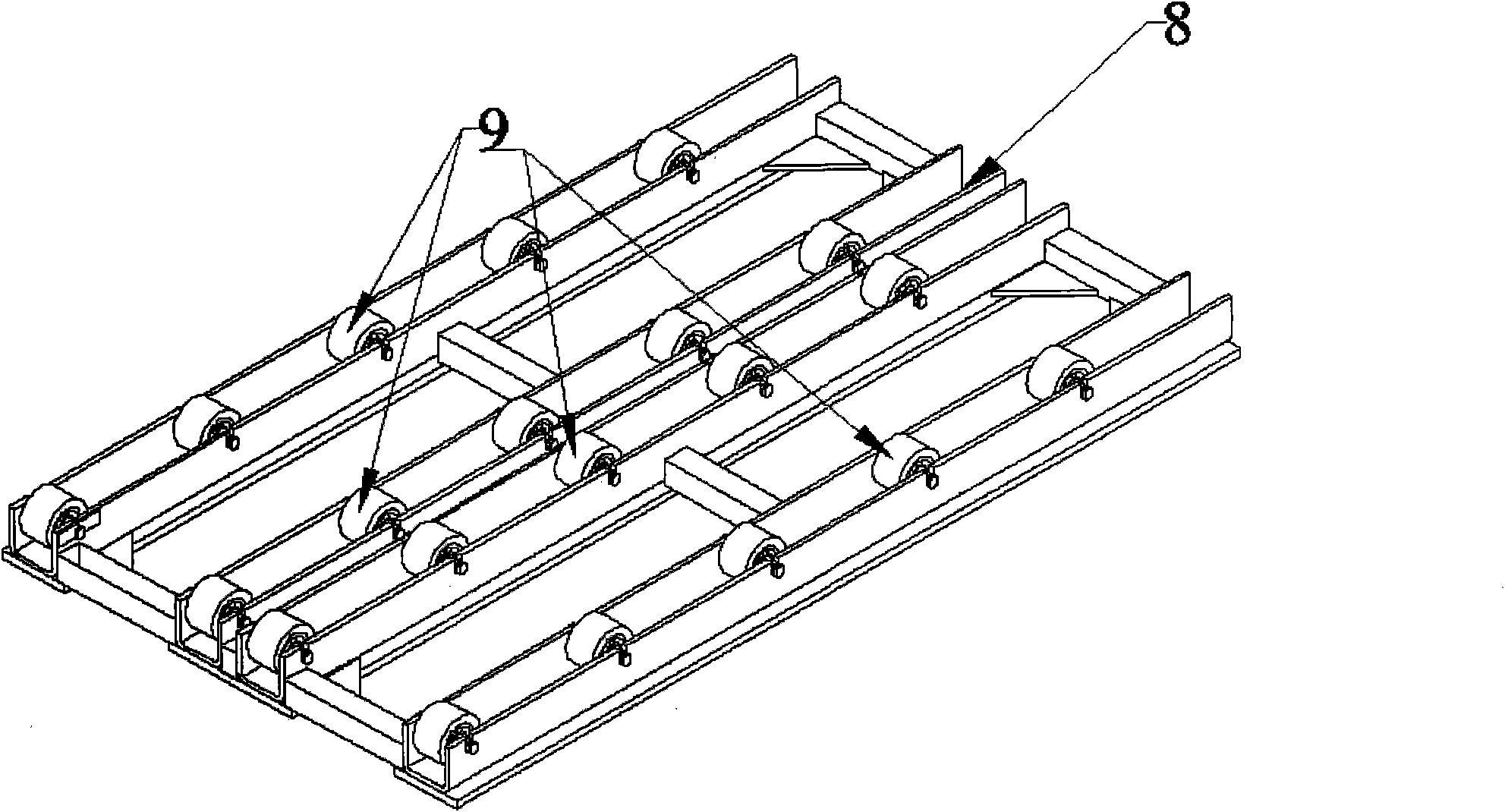

[0024] Such as figure 2 , 3 As shown, two roller ways 14, 15 are arranged at the corresponding positions of the two bottom edges of the inner box...

Embodiment 2

[0027] The difference between this embodiment and the irradiation container inner box transposition device of the above-mentioned irradiation device is that there are three inner boxes, and there are three sets of corresponding rollers on the inner box support and the outer box support.

[0028] Operation method of the irradiation container inner box transposition device of the irradiation device of the present invention

[0029] Such as Figure 4 As shown, the operation process is as follows:

[0030] (1) Place the two inner boxes in sequence in the irradiation box for irradiation;

[0031] (2) When the irradiation box 1 moves to the transposition position, the box inner bracket 2 is aligned with the box outer bracket 3 (see the transposition operation diagram figure 1 );

[0032] (3) Pull out the box body A and box body B from the irradiation box 1 to the bracket 3 outside the box (see the transposition operation diagram figure 2 );

[0033] (4) Move the track moving d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com