Production method for regular hexagonal prism-shaped battery case

A manufacturing method, a hexagonal technology, applied to battery pack components, circuits, electrical components, etc., can solve the problems of battery pack disconnection, damage, poor mechanical stability of the battery pack, etc., achieve effective use, easy method, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for manufacturing a regular hexagonal cylindrical battery case is manufactured according to the following steps:

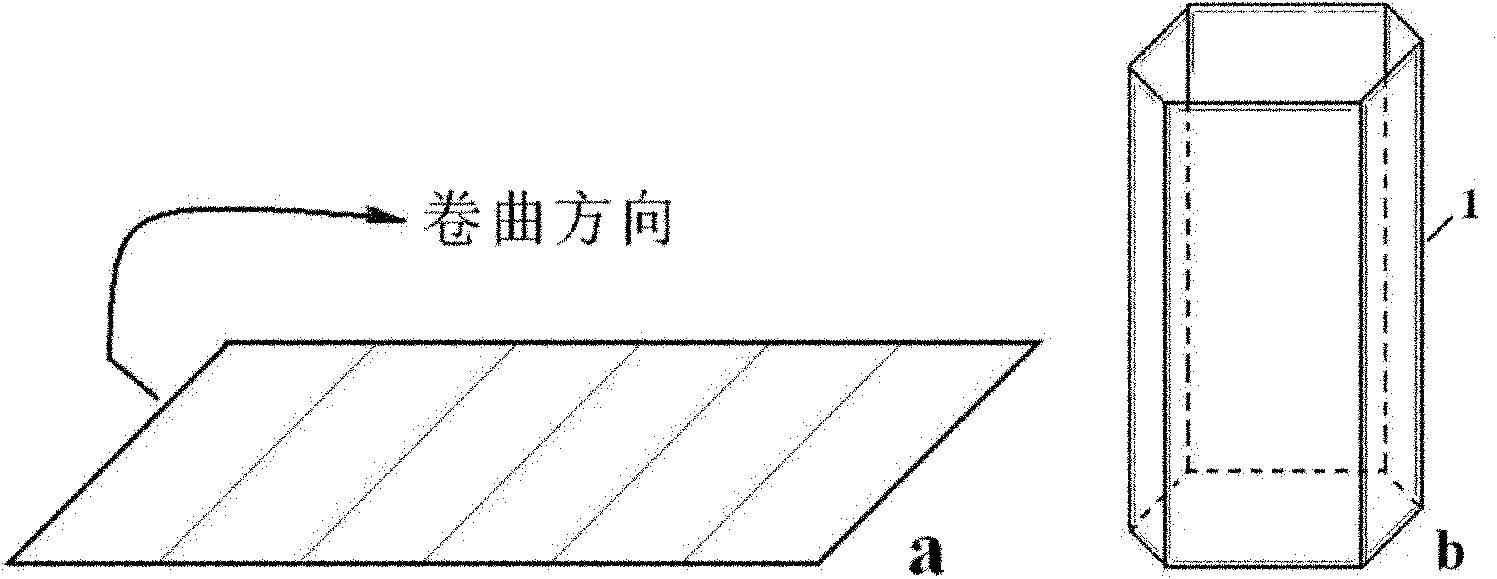

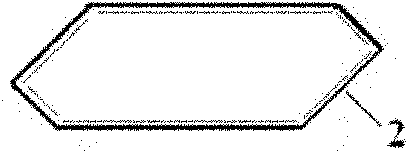

[0024] In the first step, the stainless steel plate with a thickness of 0.2mm is cut into a square plate with a size of 6.0×2.5cm ( figure 1 a), and a regular hexagonal plate with a side length of 1.0cm, that is, the bottom shell 2 ( figure 2 );

[0025] The second step is to press the cut square plate into a regular hexagonal column with a side length of 1.0 cm and a height of 2.5 cm;

[0026] In the third step, the two sides of the cylinder are welded by laser to obtain the battery case 1 ( figure 1 b);

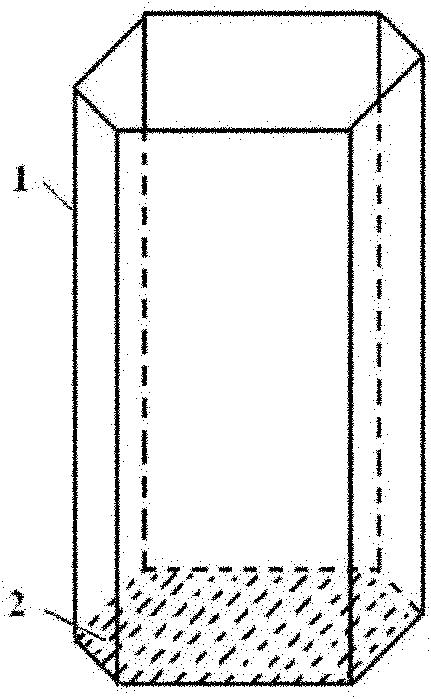

[0027] The fourth step is to weld one end of the shell 1 to the edge of the bottom shell 1 ( image 3 ).

Embodiment 2

[0029] A method for manufacturing a regular hexagonal cylindrical battery case is manufactured according to the following steps:

[0030] The first step is to cut the plate with a thickness of 1.0mm into a square plate with a size of 20×10cm ( figure 1 a), and a regular hexagonal plate with a side length of 3.5cm, that is, the bottom shell 2 ( figure 2 );

[0031] The second step is to press the cut square plate into a regular hexagonal column with a side length of 3.5cm and a height of 10cm;

[0032] In the third step, the two sides of the cylinder are welded by laser to obtain the battery case 1 ( figure 1 b);

[0033] The fourth step is to weld one end of the shell 1 to the edge of the bottom shell 1 ( image 3 ).

Embodiment 3

[0035] A method for manufacturing a regular hexagonal cylindrical battery case is manufactured according to the following steps:

[0036] In the first step, the nickel-plated steel plate with a thickness of 2.0mm is cut into a square plate with a size of 75×30cm ( figure 1 a), and a regular hexagonal plate with a side length of 12.5cm, that is, the bottom shell 2 ( figure 2 );

[0037] The second step is to press the cut square plate into a regular hexagonal column with a side length of 12.5cm and a height of 30cm;

[0038] In the third step, the two sides of the cylinder are welded by laser to obtain the battery case 1 ( figure 1 b);

[0039] The fourth step is to weld one end of the shell 1 to the edge of the bottom shell 1 ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com