Die head for forming multilayered resin and extruder having the same

A technology of extrusion molding machine and die head, which can be applied to other household appliances and other directions, can solve the problems of difficult-to-melt resin distribution and supply, and can not flow paths, etc., and achieve the effect of reducing loss and dispersion, preventing capture, and miniaturizing the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] A die for forming a multilayer resin and an extrusion molding machine having the die according to a first embodiment of the present invention will now be described with reference to the drawings.

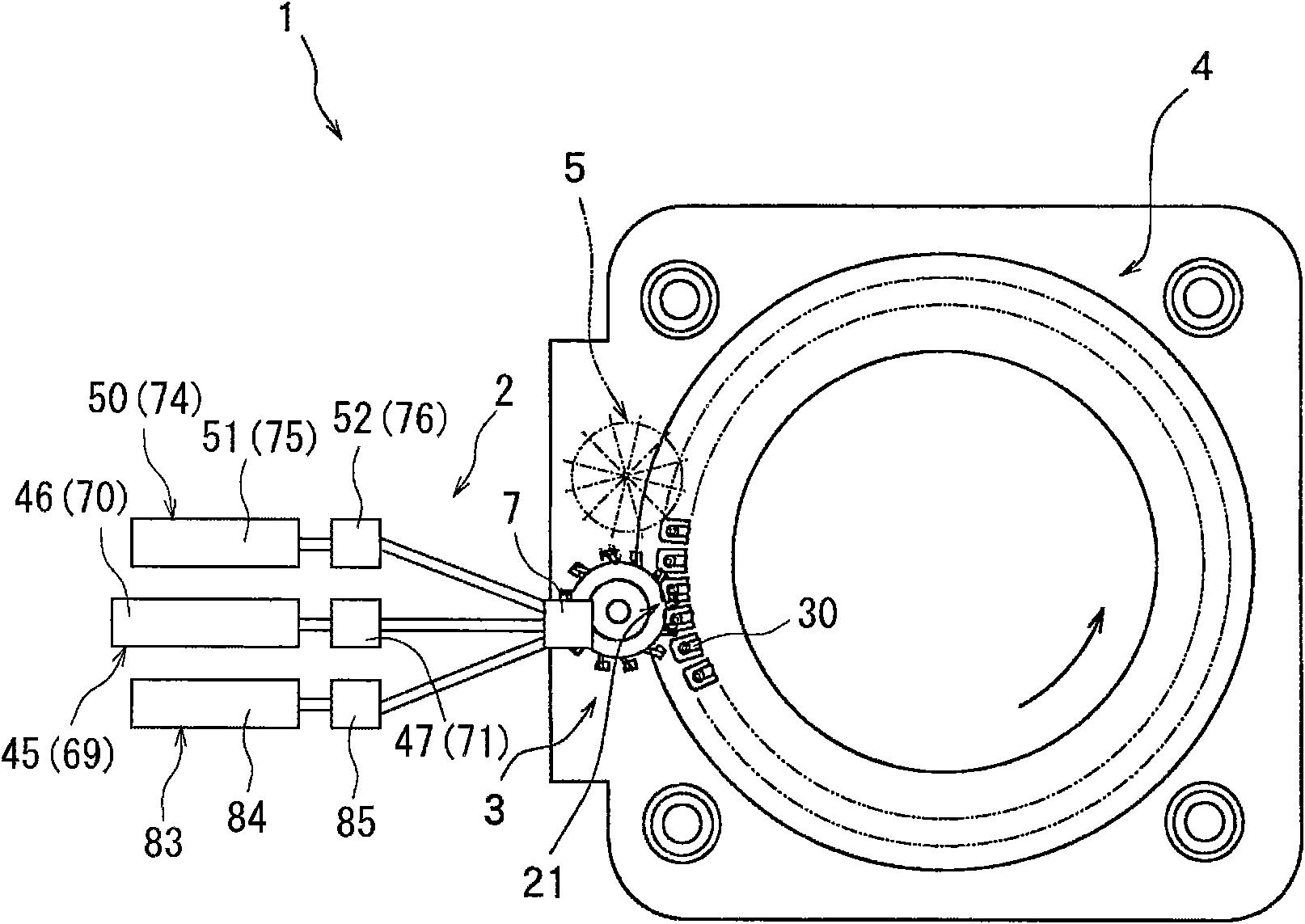

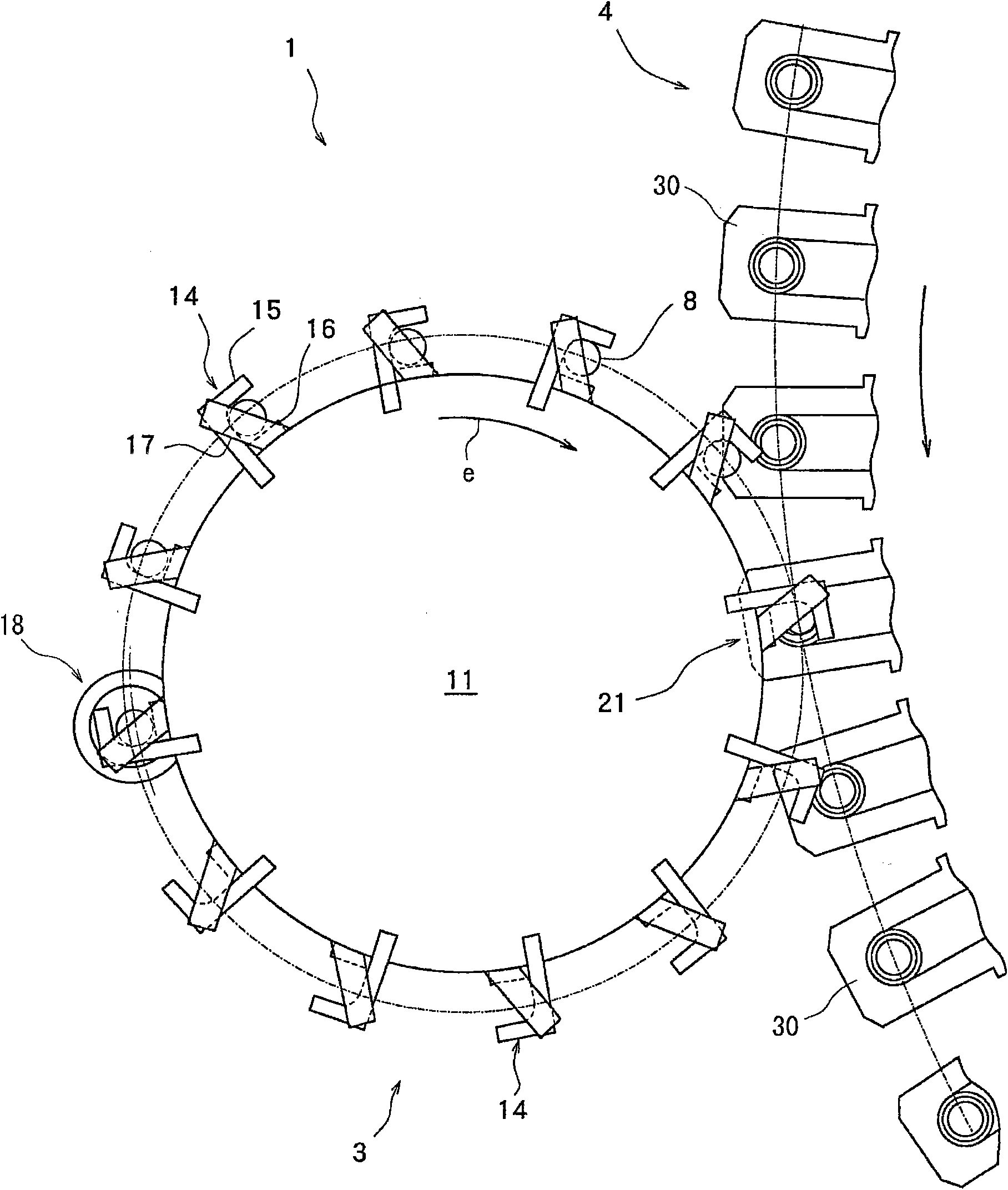

[0064] figure 1 is a plan view schematically showing a molding system 1 for performing compression molding using an extrusion molding machine for forming a die for multilayer resin according to the present invention, figure 2 are shown on an enlarged scale figure 1 Plan view of part of the compression molding section of the molding system.

[0065] The molding system 1 includes an extrusion molding machine 2 according to the present invention, a synthetic resin delivery device 3 , a compression molding device 4 and a discharge device 5 .

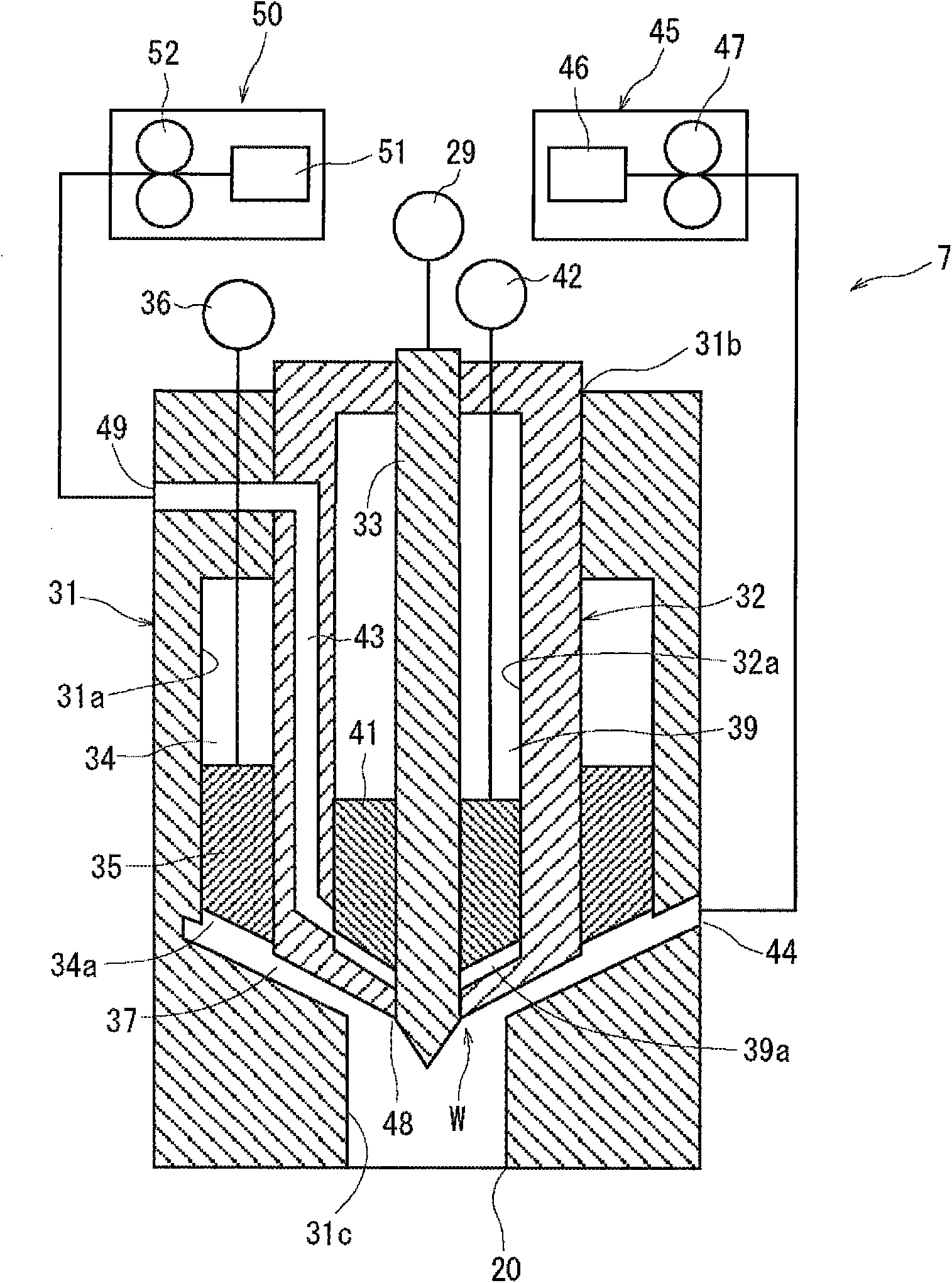

[0066] The extrusion molding machine 2 is equipped with a plurality of molten resin supply parts 45, 50 and 83, that is, a main layer molten resin supply part 45 using different molten resins as raw materials, a core layer molten resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com