Pneumatic tire for heavy loads

A technology of pneumatic tires and steel cords, which is applied to the reinforcement layers of pneumatic tires, tire parts, vehicle parts, etc., can solve problems such as the reduction of circumferential rigidity, and achieve the effect of achieving durability and improving lightweight effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

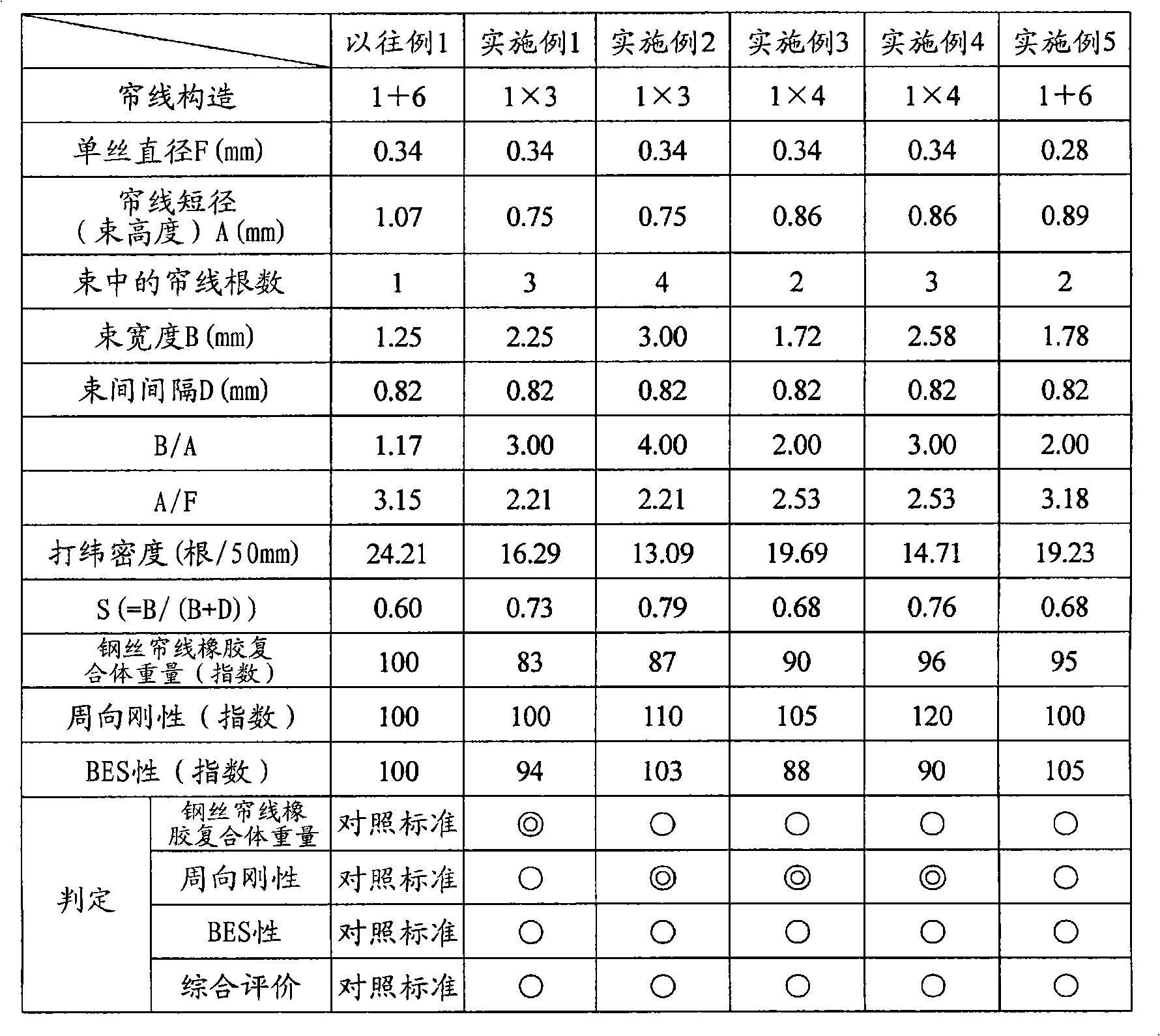

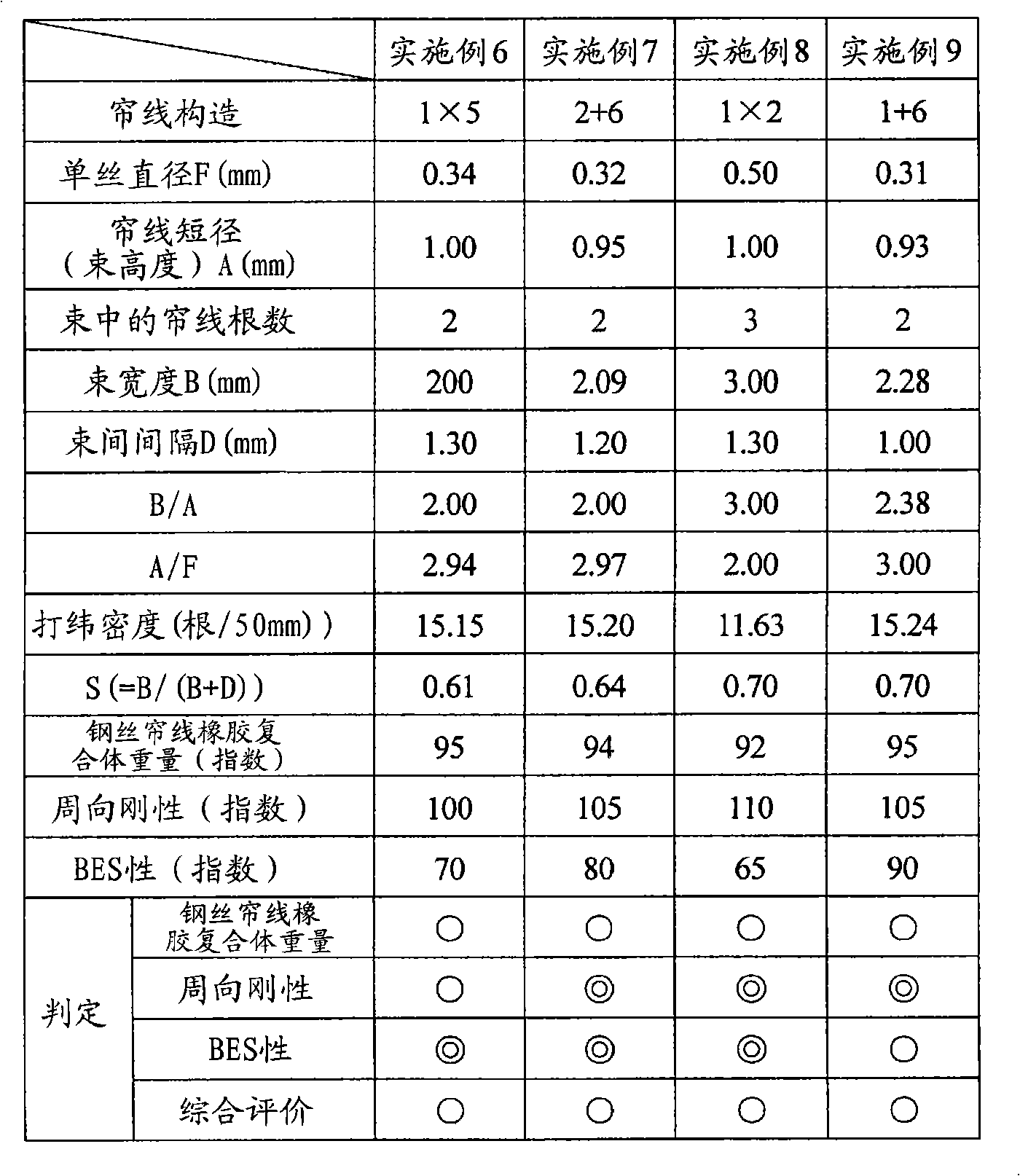

[0041] Hereinafter, the present invention will be described in more detail using examples.

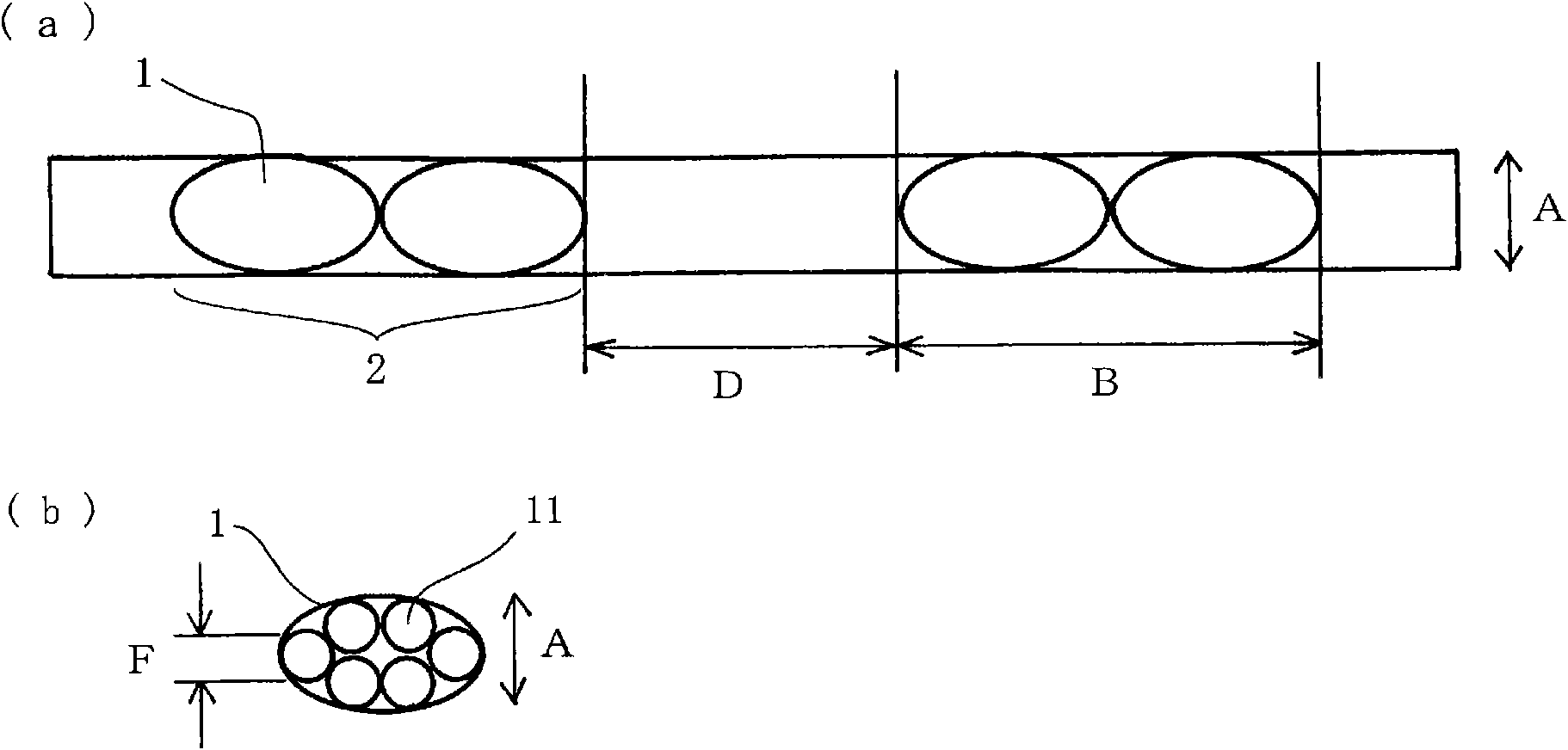

[0042] A bundled cord arrangement according to the conditions in the following table was applied to two main interlaced belt layers among the four-layer steel belt layers to manufacture a heavy-duty pneumatic tire with a tire size of 11R22.5.

[0043] Steel cord rubber compound weight

[0044] For each of the obtained test tires, the steel cord rubber composite weight was determined from the actual measured weight per unit area of the steel cord rubber composite composed of the steel cord and the rubber sheet. The results are shown by an index, where Conventional Example 1 is set to 100. Smaller values mean greater weight reduction effects.

[0045] Circumferential rigidity

[0046] For each of the obtained test tires, the outer circumference of the tire was measured after driving 100,000 km in a field test, and the circumferential rigidity thereof was obtained. Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com