Work washing apparatus

A washing machine and machine parts technology, applied in the direction of dryers, cleaning methods and utensils, local stirring dryers, etc., can solve problems that may not be considered comprehensively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

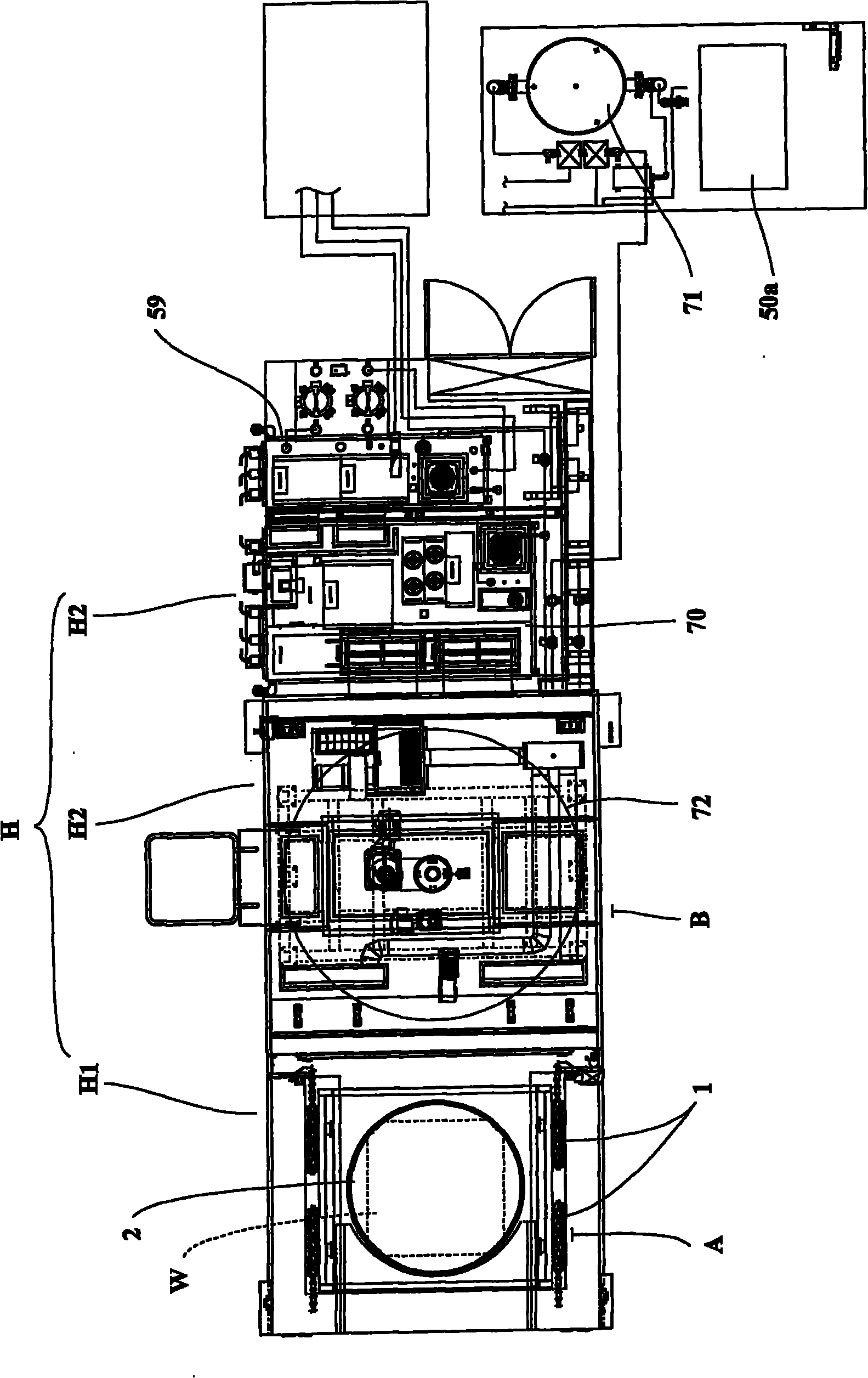

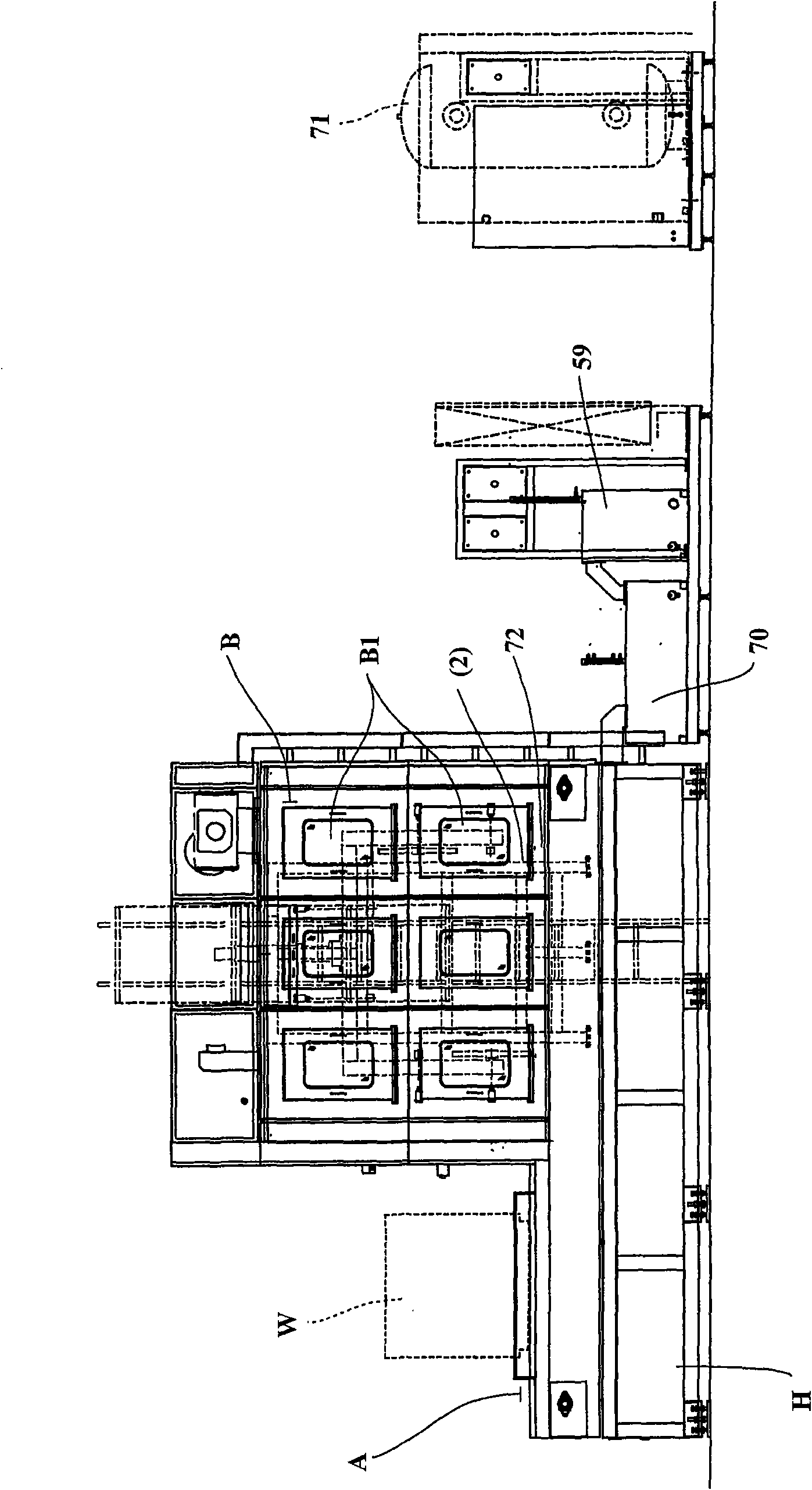

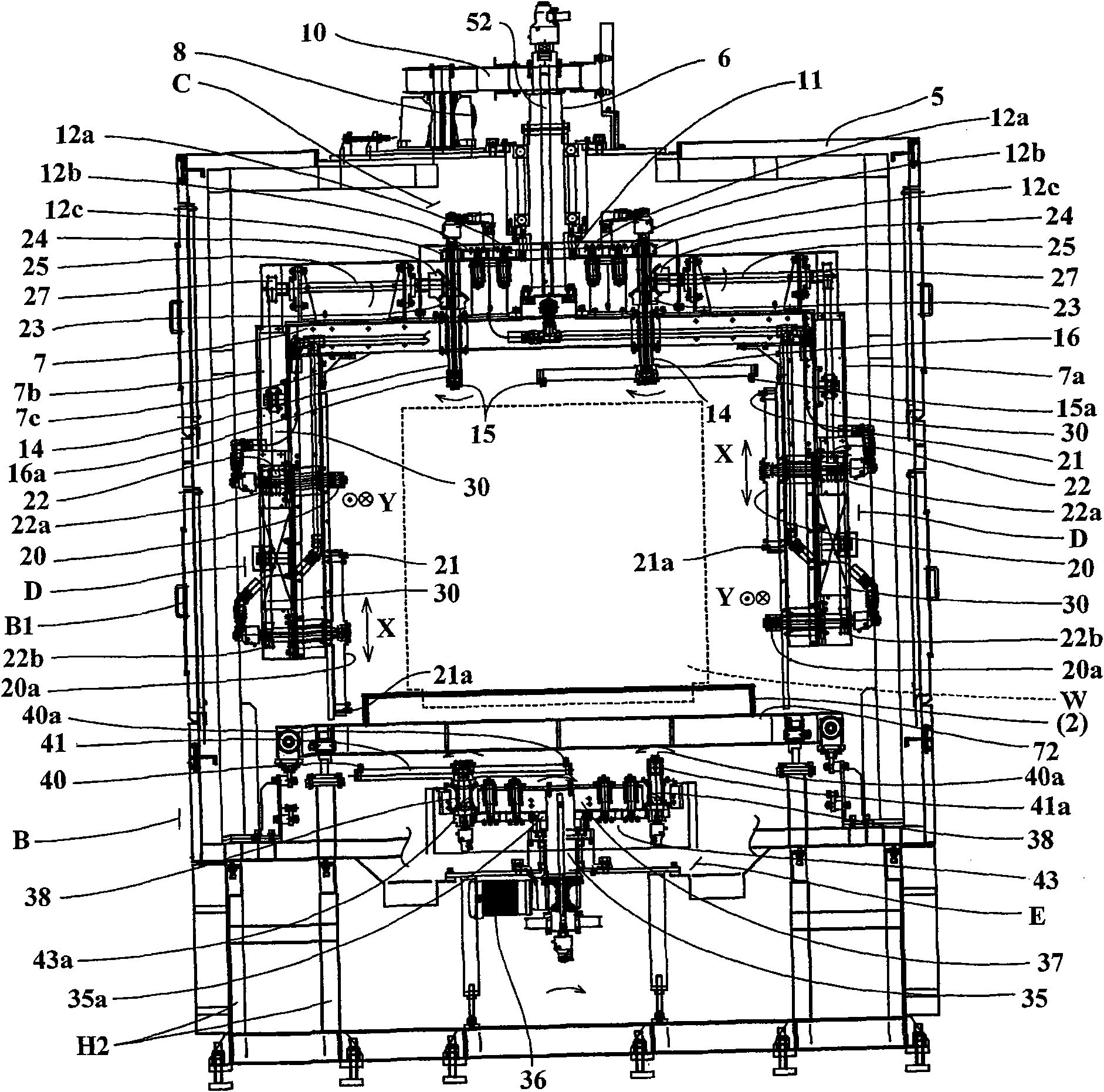

[0038] The main constituent element of the present invention is a parts cleaning machine comprising the following components: a conveying device A responsible for the forward and backward movement of the parts W; equipped with the conveying device A and treated with water and air (collectively referred to as water, etc.) (washing / drying) The processing chamber B of the large machine part W (referred to as the machine part W); the various devices arranged in the processing chamber B (the top surface cleaning device C arranged above the processing chamber B and having a nozzle that uses rotation and revolution to perform planetary motion, The side cleaning devices D and D (the side cleaning device on one side) are installed on both sides of the conveying device A and have nozzles that use rotation and revolution to perform planetary motion. The bottom surface cleaning device E) of the nozzle of planetary motion; the pipeline mechanism F for supplying and spraying water etc. of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com