Installation structure and installation method for sunroof installation plate and top cover

A technology of installation structure and installation method, applied in the directions of windows, transportation and packaging, windshields, etc., can solve the problems of weak roof strength, roof collapse, weak strength, etc., to achieve a simple and practical installation method, and avoid deformation and collapse. , to ensure the effect of the isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

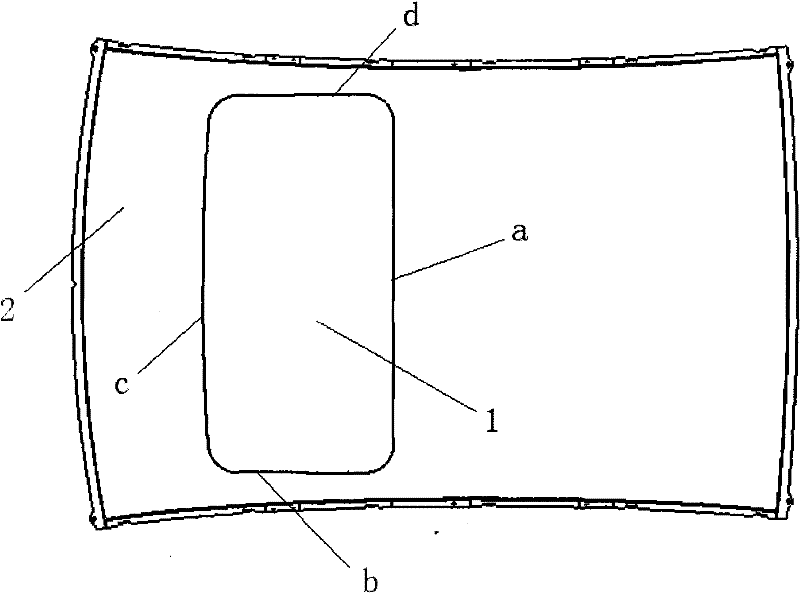

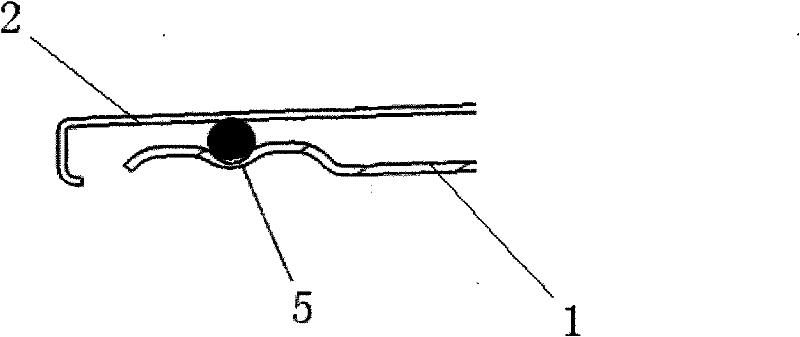

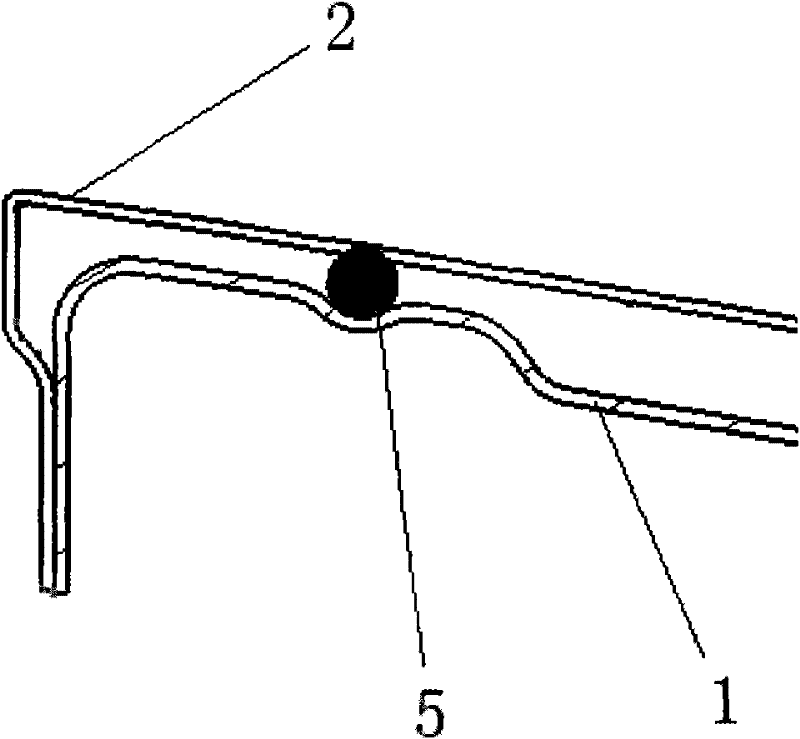

[0023] like Figure 4 , 5 As shown, the key to the installation structure of the skylight mounting plate 1 and the top cover 2 of this embodiment is that: the surrounding of the skylight mounting plate 1 is provided with a glue groove 3, wherein the glue groove 3 on the first side a is coated with two sets of Divided into epoxy resin structural glue 4, the second side b, the third side c and the fourth side d are coated with shock-absorbing glue 5 in the glue groove 3; the second side of the skylight installation plate 1 The side b, the third side c and the fourth side d are fixed to the top cover 2 by welding, and the first side a of the skylight installation plate 1 is connected to the top cover 2 by two-component epoxy resin structural adhesive 4 Glue it in place.

[0024] Epoxy resin structural adhesive 4 is composed of epoxy resin and polyamide curing agent, its T-peel strength ≥ 100N / 25mm, shear strength ≥ 15MPa, which can meet the strength requirements of skylights. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com