A kind of seismic isolation support for LNG storage tank and its installation method

An installation method and vibration isolation bearing technology, which are applied to the container filling method, the container discharge method, the installation device of the container structure, etc. The impact of the isolation effect of the bearing is large, and the installation reliability and cost are low, the fatigue life of the bearing is long, and the structure is compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

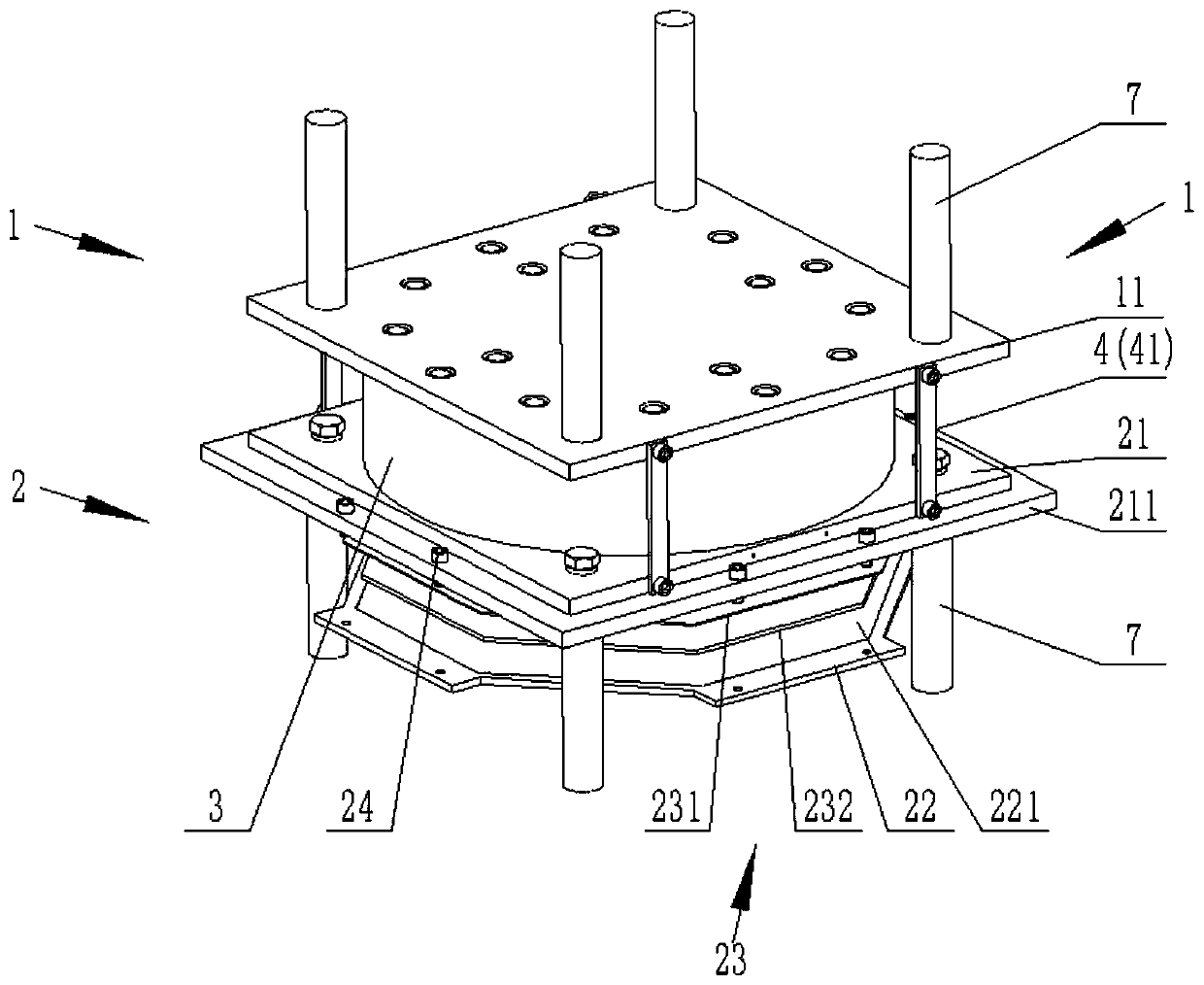

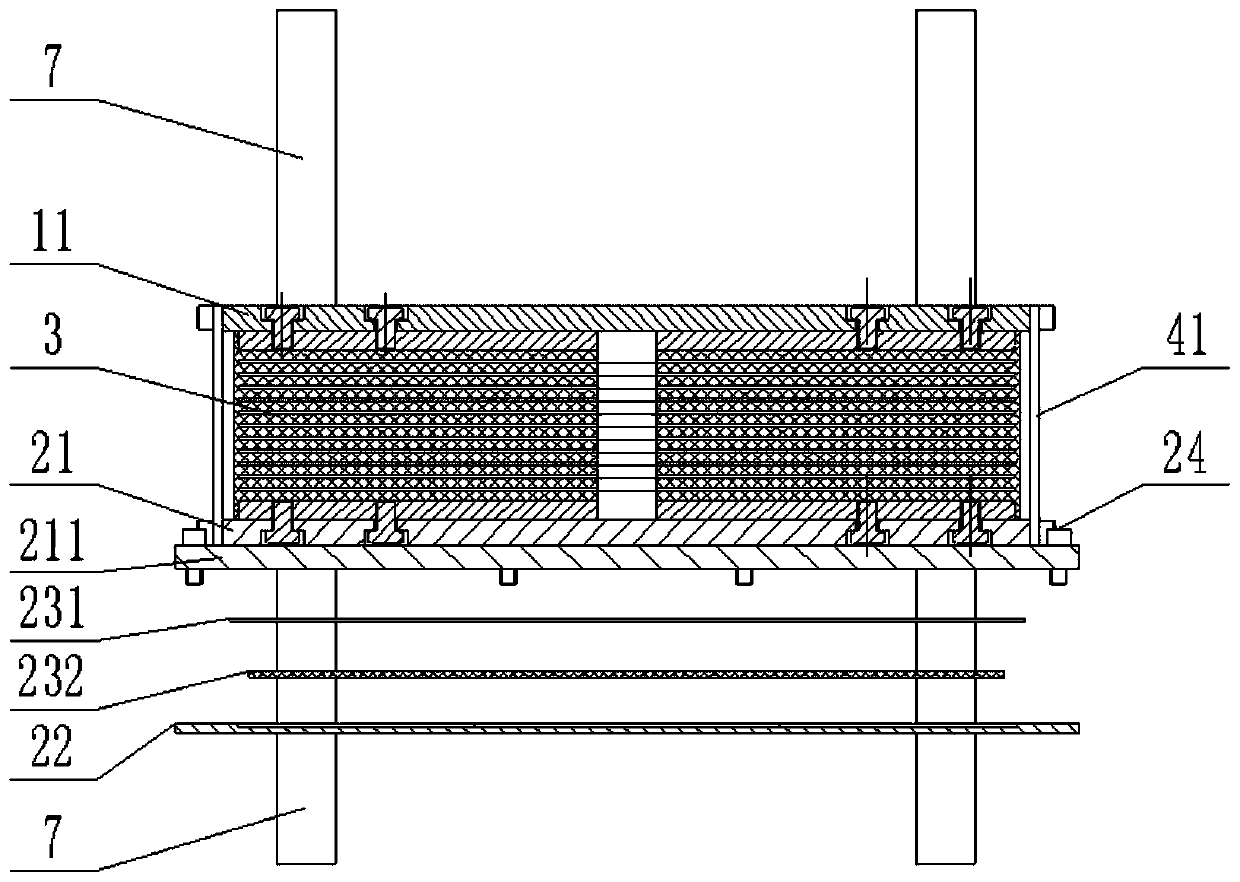

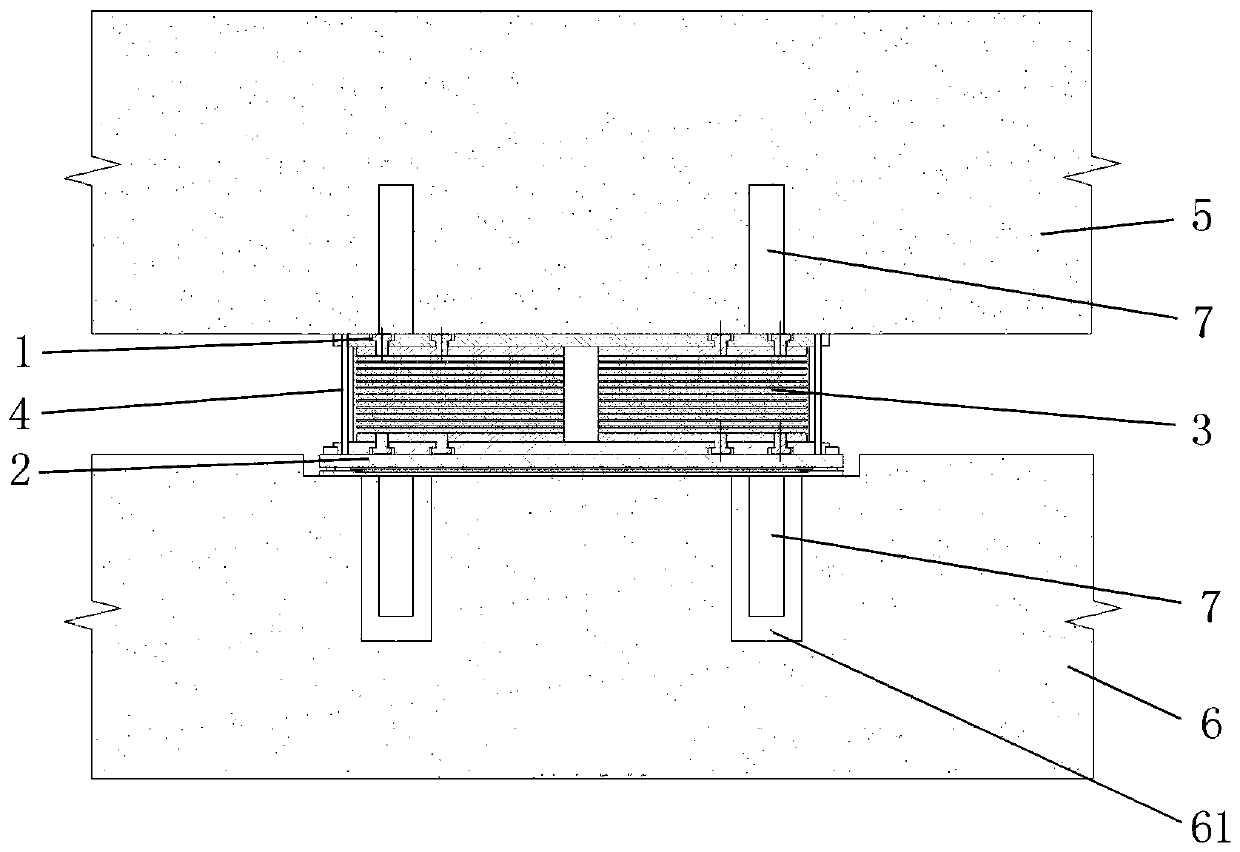

[0031] Such as figure 1 and figure 2 An embodiment of the shock-isolation bearing for LNG storage tank of the present invention is shown, and the vibration-isolation bearing for LNG storage tank can be any one of natural rubber bearing, high damping rubber bearing and lead core rubber bearing. In this embodiment, the upper seat plate assembly 1 , the lower seat plate assembly 2 and the support body 3 . Among them, the upper seat plate assembly 1 is connected with the upper concrete layer 5 through the anchor steel rod 7; the lower seat plate assembly 2 is connected with the lower concrete layer 6 through the anchor steel rod 7; the support body 3 is connected with the upper seat plate assembly 1 and the lower seat Between the plate components 2, a vibration i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com