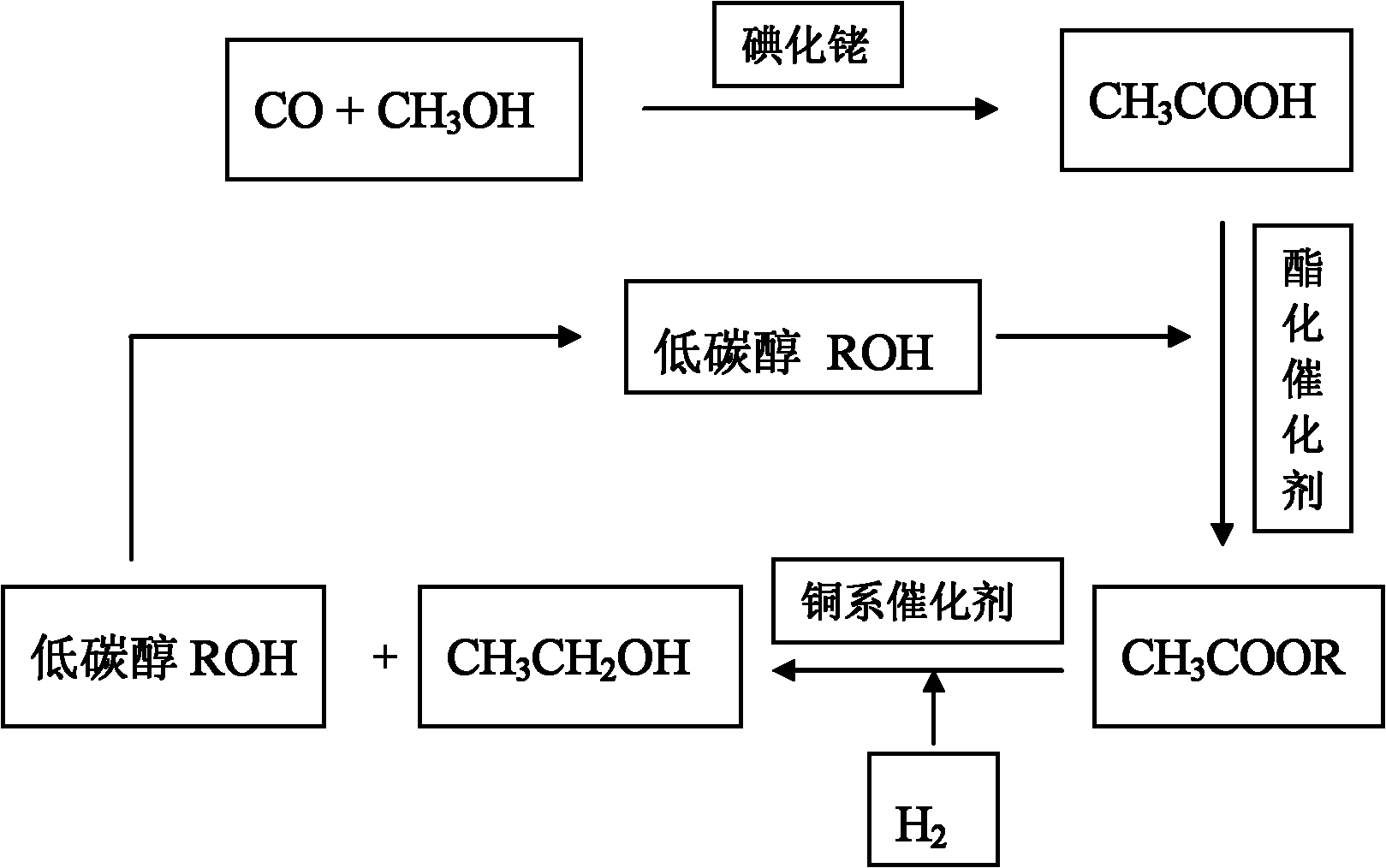

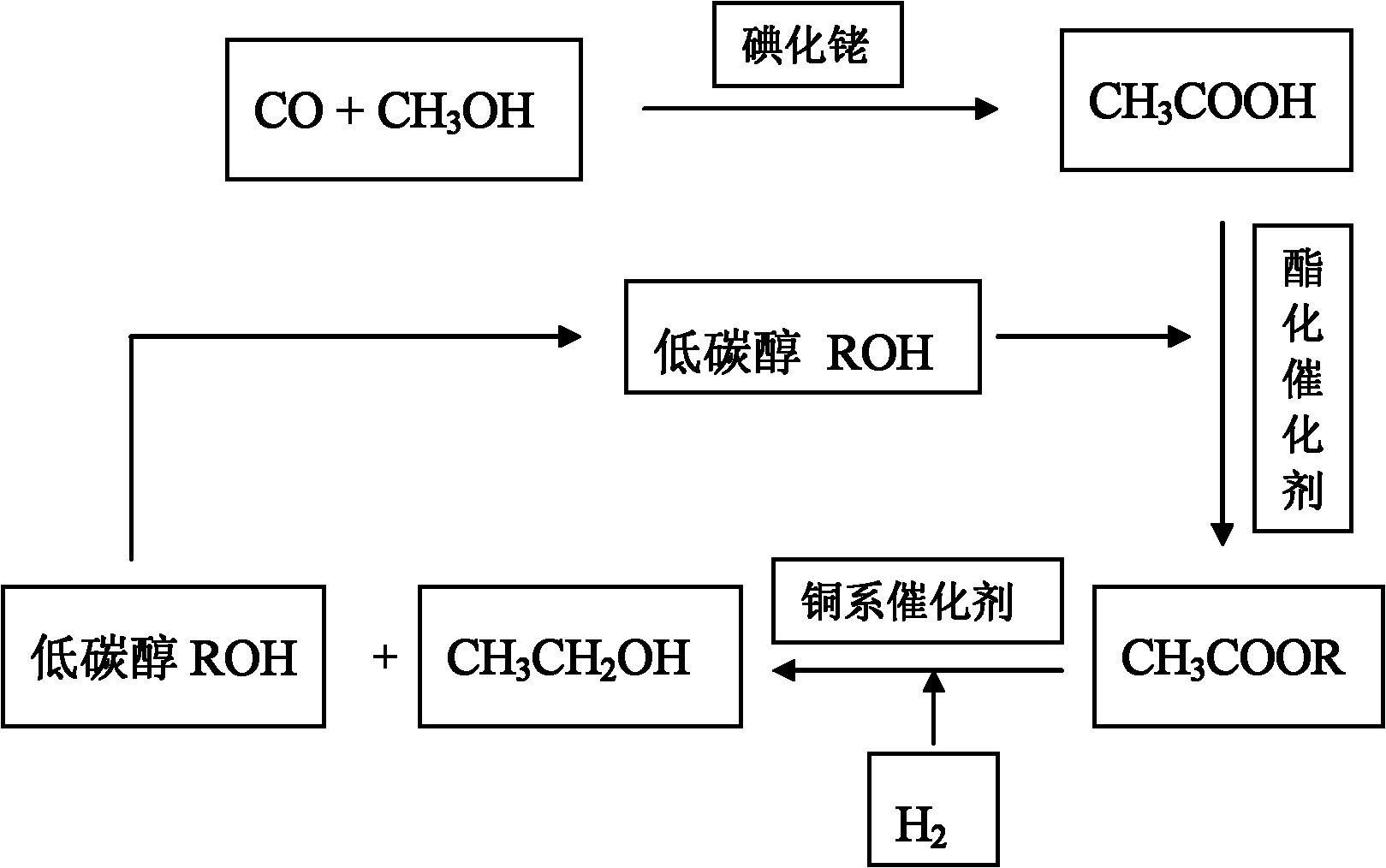

Method for indirectly synthesizing ethanol by using carbon monoxide and hydrogen

A carbon monoxide and hydrogen technology, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of no industrialization, low ethanol selectivity, and large amount of catalyst, and achieves low price and high content of heavy components. The effect of less and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The synthesis gas from the coal gasification furnace is subjected to a series of processes of dust removal, wet desulfurization, fine desulfurization, pressure swing adsorption, and catalytic dehydrogenation to obtain carbon monoxide gas with a purity of ≥98.5% and hydrogen with a purity of ≥99%. The purity is calculated by volume percentage, and the obtained Carbon monoxide gas and methanol are catalyzed by rhodium iodide in a high-pressure reactor, and the temperature is 195 ° C and the pressure is 3.0 MPa. The low-pressure carbonylation synthesizes acetic acid; the obtained acetic acid is sent to the reactive distillation column after dehydration and refinement. In the distillation tower, acetic acid and methanol are esterified under the catalysis of sulfuric acid at 60 ℃ and normal pressure to form methyl acetate. After dehydration and purification, the purity of methyl acetate is greater than 99% (calculated by mass percentage), which is used as the subsequent cataly...

Embodiment 2

[0035] The synthesis gas from the coal gasification furnace is subjected to a series of processes of dust removal, wet desulfurization, fine desulfurization, pressure swing adsorption, and catalytic dehydrogenation to obtain carbon monoxide gas with a purity of ≥98.5% and hydrogen with a purity of ≥99%. Gas and methanol are catalyzed by rhodium iodide in a high-pressure reactor, and carbonylated at a temperature of 185°C and a pressure of 2.0 MPa to synthesize acetic acid at a low pressure; In the tower, acetic acid and ethanol are esterified under the catalysis of dodecylbenzenesulfonic acid at 70°C under normal pressure to form ethyl acetate. After dehydration and refining, the purity of ethyl acetate is greater than 99% (calculated by mass percentage). Catalytic hydrogenation feedstock;

[0036] Preparation of copper-based catalyst: 220gCu(NO 3 ) 2 ·3H 2 O, 36.6gZn(NO 3 ) 2 ·6H 2 O, 31.8gMg(NO 3 ) 2 ·6H 2 O and 36.8g Al(NO 3 ) 3 9H 2 O is placed in a beaker, and...

Embodiment 3

[0039] The synthesis gas from the coal gasification furnace is subjected to a series of processes of dust removal, wet desulfurization, fine desulfurization, pressure swing adsorption, and catalytic dehydrogenation to obtain carbon monoxide gas with a purity of ≥98.5% and hydrogen with a purity of ≥99%. The purity is calculated by volume percentage, and the obtained Carbon monoxide gas and methanol are catalyzed by rhodium iodide in a high-pressure reactor, and the temperature is 200 ° C and the pressure is 3.3 MPa. The low-pressure carbonylation synthesizes acetic acid; the obtained acetic acid is dehydrated and refined and then sent to the reactive distillation column. In the distillation tower, acetic acid and n-propanol are esterified under the catalysis of molecular sieves at 85°C under normal pressure conditions to form n-propyl acetate. After dehydration and purification, the purity of n-propyl acetate is greater than 99% (calculated by mass percentage). raw material for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap