Method for controlling output of belt weigher system

A control method and technology of belt scales, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of control lag, unable to respond in time, control effect overshoot and large reaction, etc., to achieve effect overshoot Small, solve the contradiction between overshoot and response time, the effect of small fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

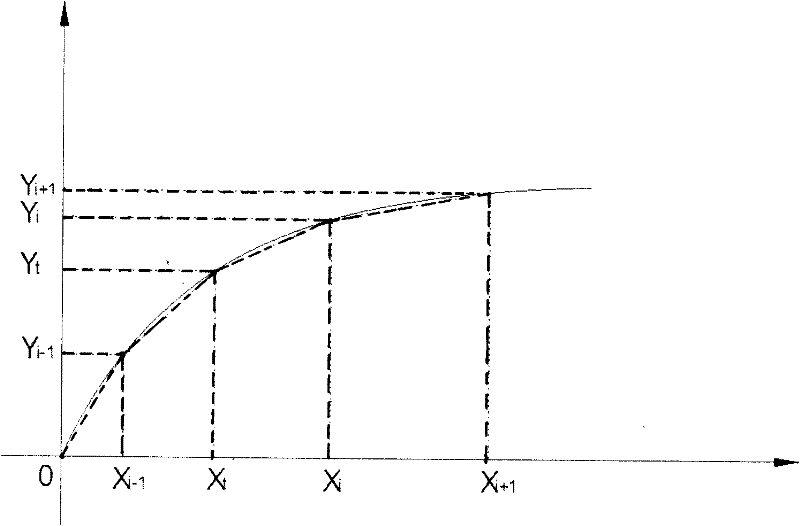

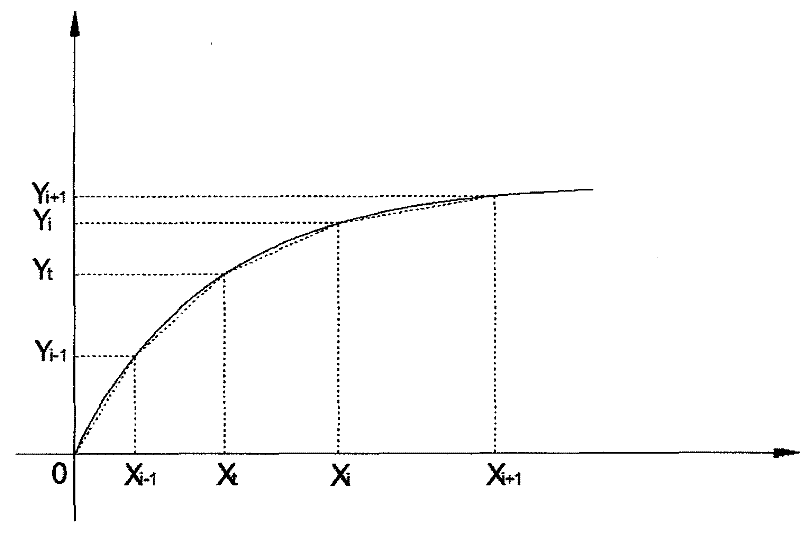

[0013] First of all, the non-linearity of the belt scale control system is mainly concentrated in two parts: 1) the characteristics of the analog control output AO of the instrument cannot be completely linear; 2) the output of the frequency converter and the motor are not linear.

[0014] Suppose the control model is

[0015] y=f(x1,x2)(1)

[0016] y is the output of the belt scale system, x1 is the analog control output of the instrument, and x2 is the output of the inverter and the motor. Because of the nonlinearity of x1 and x2, the intersection of these two nonlinearities makes it difficult to establish the control model f(x1, x2) function.

[0017] In view of the above two problems, the linear adjustment in this scheme is divided into two parts, namely:

[0018] 1. Make linear compensation adjustment to the characteristic x1 of the analog control output AO of the instrument, so that it has an ideal linear output.

[0019] 2. Make a linear compensation adjustment to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com