Method for synthesizing special resin for polypropylene cast film

A polypropylene casting and synthesis method technology, which is applied in the field of synthetic resins, can solve problems such as large fluctuations in product quality and difficulties in long-term production of polypropylene devices, and achieve excellent physical and mechanical properties, compoundability and anti-blocking properties , The effect of improving processability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

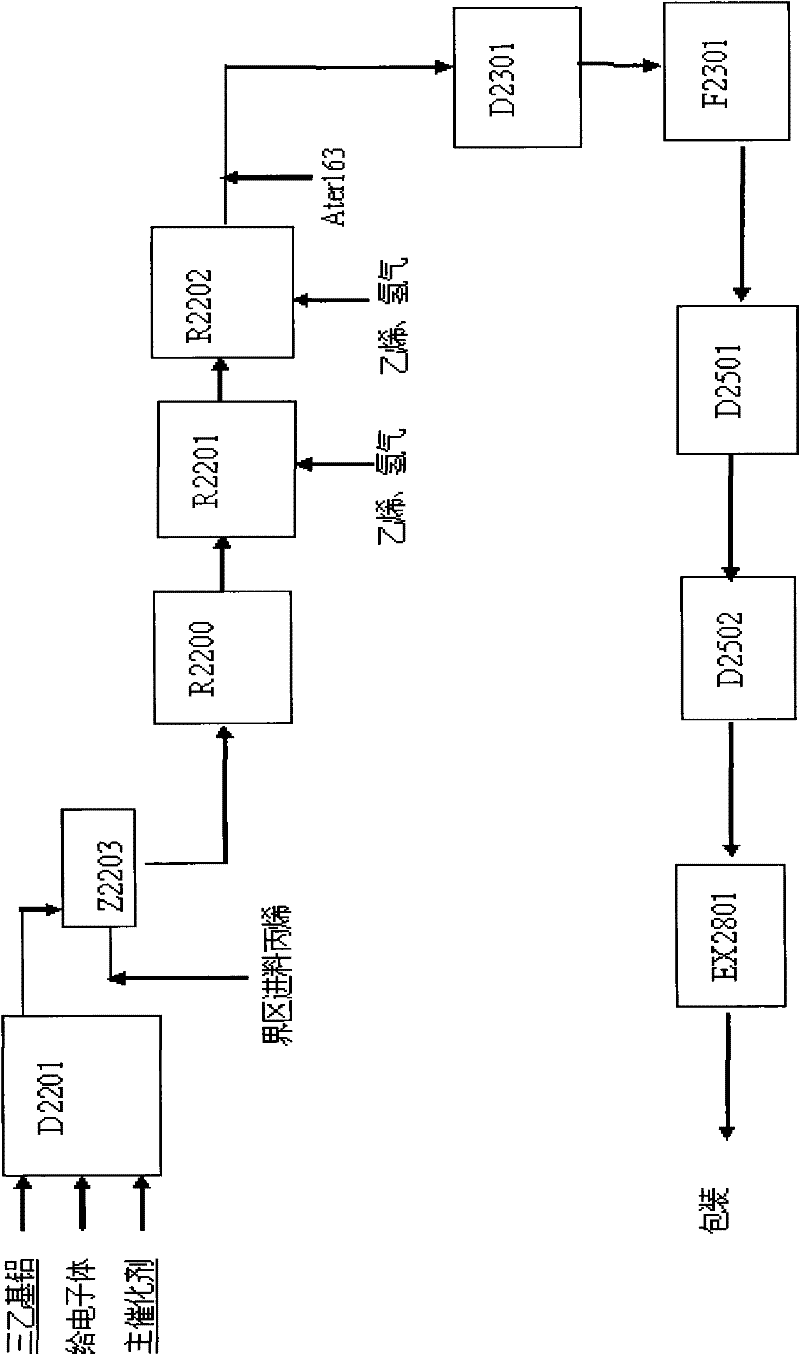

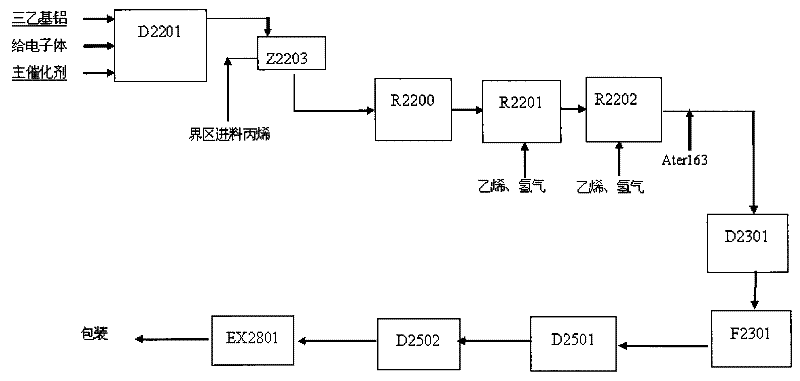

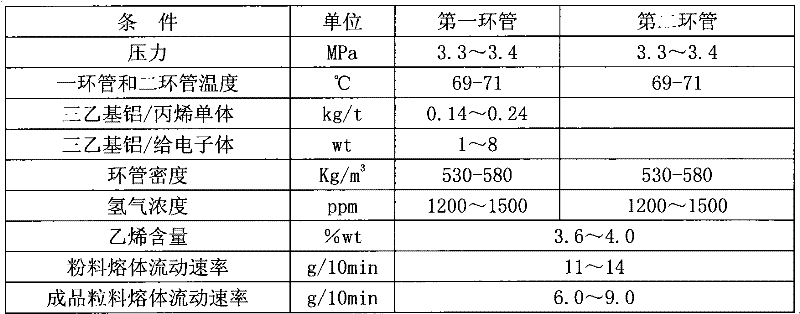

[0037] (device load 6t / h): The main catalyst (120g / h), triethylaluminum (840g / h) and electron donor (105g / h~840g / h) are in the pre-contact tank D2201 at about 10 ℃, fully Stir to mix to form a complex. The complex compound overflowed from D2201 is mixed with cold propylene (20°C) (6t / h) in Z2203 (inline mixer) and then enters the prepolymerization reactor R2200, at 20°C, 3.4Mpa pressure, the reaction After about 4 minutes, it enters a loop reactor R2201, and at the same time, ethylene (about 116kg / h) and hydrogen gas with a controlled molecular weight are input into a loop reactor R2201, and the polymerization reaction is carried out in a loop reactor. The operating temperature is 70°C, the pressure is 3.4Mpa, a part of propylene is polymerized, and the remaining liquid propylene is used as the flow carrier of the solid polymer, and the slurry concentration is controlled at 50-55%wt. The slurry, propylene and ethylene (116kg / h) and hydrogen from the boundary zone from R2201 e...

Embodiment 2

[0040] (Device load 6t / h): The main catalyst (150g / h), triethylaluminum (1140g / h) and electron donor (142.5g / h~1140g / h) are in the pre-contact tank D2201 at about 10°C, Stir well to mix to form a complex center. The complex compound overflowed from D2201 is mixed with cold propylene (20°C) (6t / h) in Z2203 (inline mixer) and then enters the prepolymerization reactor R2200. At 20°C and 3.4Mpa pressure, the reaction After about 4 minutes, it enters a loop polymerization reactor R2201, and at the same time, ethylene (about 116kg / h) and hydrogen gas with a controlled molecular weight are input into a loop polymerization reactor R2201, and the polymerization reaction is carried out in a loop polymerization reactor. The operating temperature is 70°C, the pressure is 3.4Mpa, a part of propylene is polymerized, and the remaining liquid propylene is used as the flow carrier of the solid polymer, and the slurry concentration is controlled at 50-55%wt. The slurry, propylene and ethylene ...

Embodiment 3

[0043] (Device load 6t / h): The main catalyst (180g / h), triethylaluminum (1440g / h) and electron donor (180~1440g / h) are fully stirred and mixed in the pre-contact tank D2201 at about 10°C form a complexing center. The complex compound overflowed from D2201 is mixed with cold propylene (20°C) (6t / h) in Z2203 (inline mixer) and then enters the prepolymerization reactor R2200. At 20°C and 3.4Mpa pressure, the reaction After about 4 minutes, it enters into a loop polymerization reactor R2201, and at the same time, ethylene (about 116kg / h) and hydrogen with a controlled molecular weight are input into a loop polymerization reactor R2201, and the polymerization reaction is carried out in a loop polymerization reactor. The operating temperature is 70°C, the pressure is 3.4Mpa, a part of propylene is polymerized, and the remaining liquid propylene is used as the flow carrier of the solid polymer, and the slurry concentration is controlled at 50-55%wt. The slurry, propylene and ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com