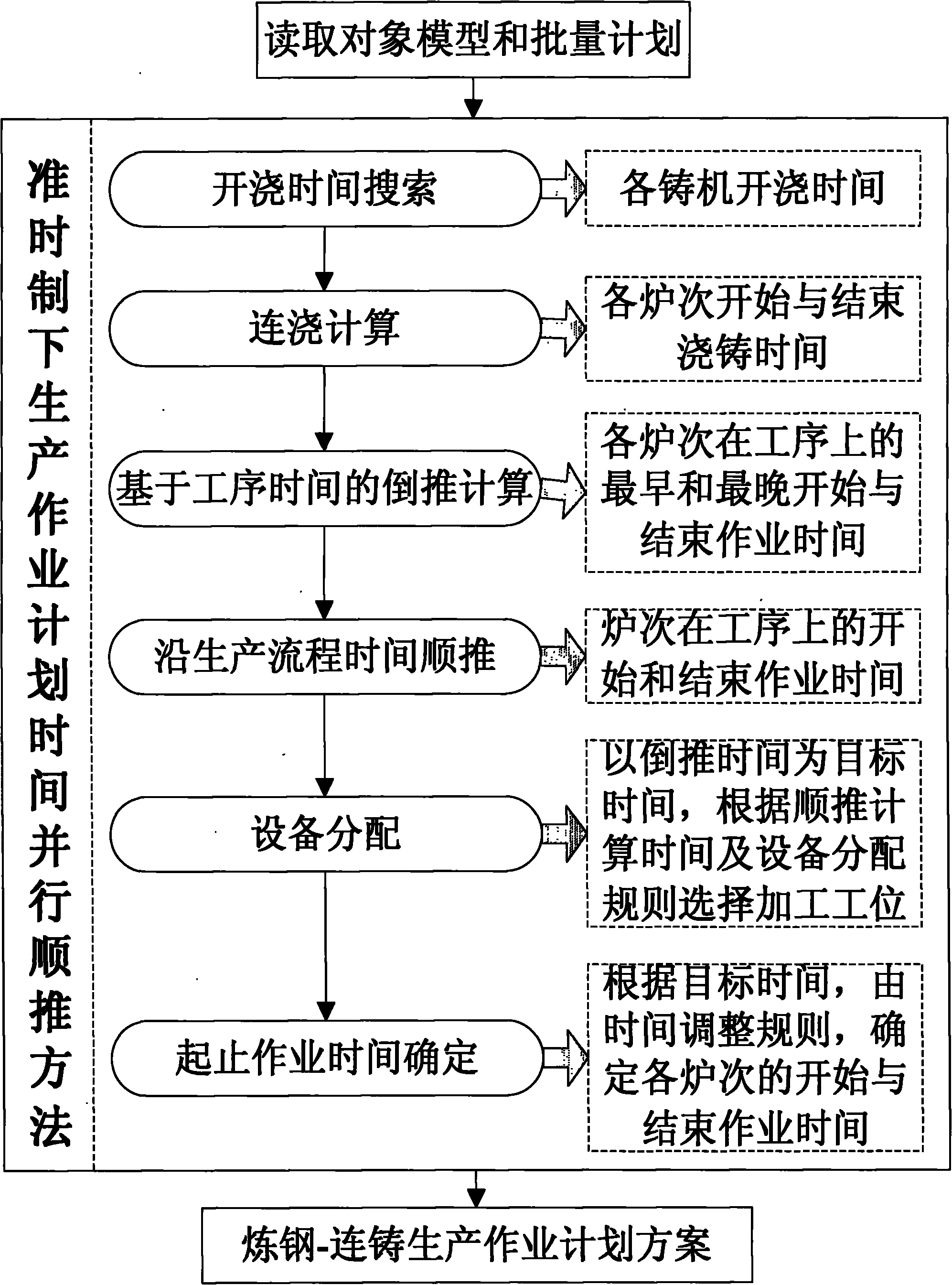

Just-in-time-based parallel forward calculation programing method for steel-making production planned time

A production planning, just-in-time technology, used in computing, instrumentation, data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] On the basis of establishing the underlying object model of the production process network, and based on the just-in-time steelmaking production operation planning time parallel and forward programming method, the steelmaking-continuous casting production operation plan for N furnaces passing through the corresponding stations in M processes is compiled. The inventive method is described in detail as follows:

[0098] Step 1 Initialize

[0099] Read the underlying object model of the production process network, batch planning, and the scheduled start-up time of each continuous casting machine;

[0100] Step 2 Continuous pouring calculates the start pouring time of each heat x i,M,k

[0101] According to the starting and pouring time of each continuous casting machine, the continuous casting calculation of formula (1) is used to obtain the start and end pouring time of each heat on the continuous casting;

[0102] Step 3: Calculate the target start time x' of each h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com