Method for preparing carbon aerogel cladded LiMnPo4/C

A carbon airgel and coating technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of low output of microwave and hydrothermal methods, long synthesis time, low heat utilization rate, etc., and achieve cycle performance Good, inexpensive, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

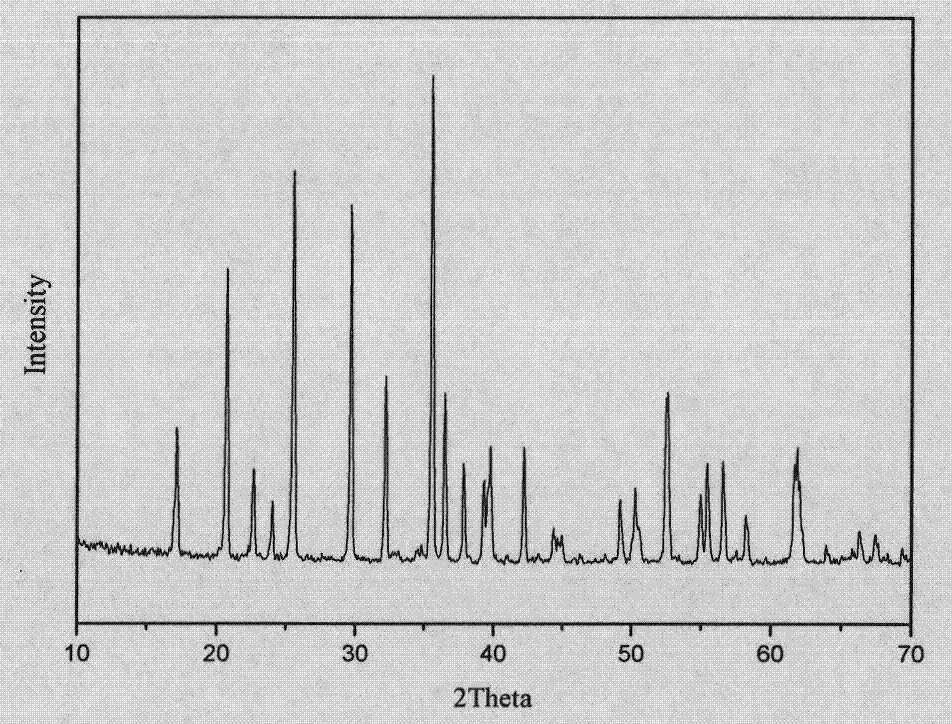

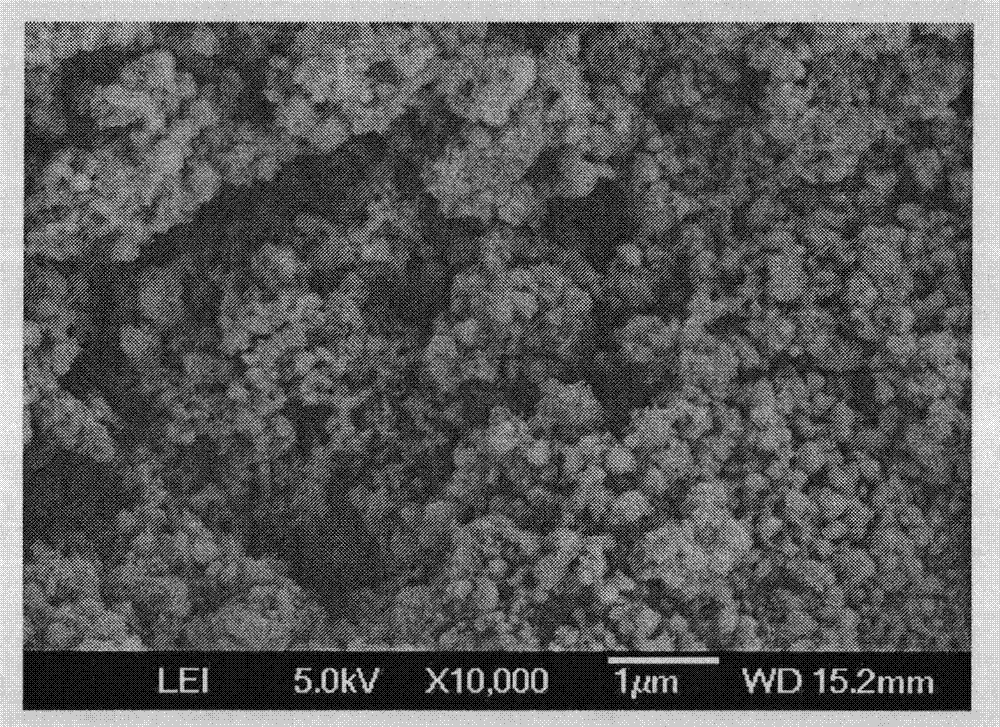

[0032] 1) Weigh 0.02 mol of resorcinol, 0.2 mol of lithium hydroxide, 0.2 mol of ammonium dihydrogen phosphate, prepare a solution, add to the solution prepared by 0.04 mol of formaldehyde solution and 0.2 mol of manganese carbonate, add 0.002 mol of organic Catalyst citric acid. The mixed solution was stirred at a constant temperature of 80°C for 6 hours, and the pH value was adjusted to about 8.9 with ammonia water, and stirred until a gel was formed;

[0033] 2) The obtained gel was vacuum-dried at 150° C. for 3 hours, and the solvent was evaporated to obtain a dry gel; then, it was ball-milled on a planetary ball mill for 6 hours at a speed of 600 r / min. After fully grinding, it is calcined at 700°C for 10 hours under the protection of reducing atmosphere, and the gas flow rate is 0.1-10L / min. After cooling down to room temperature, LiMnPO coated with carbon airgel can be obtained. 4 / C Composite.

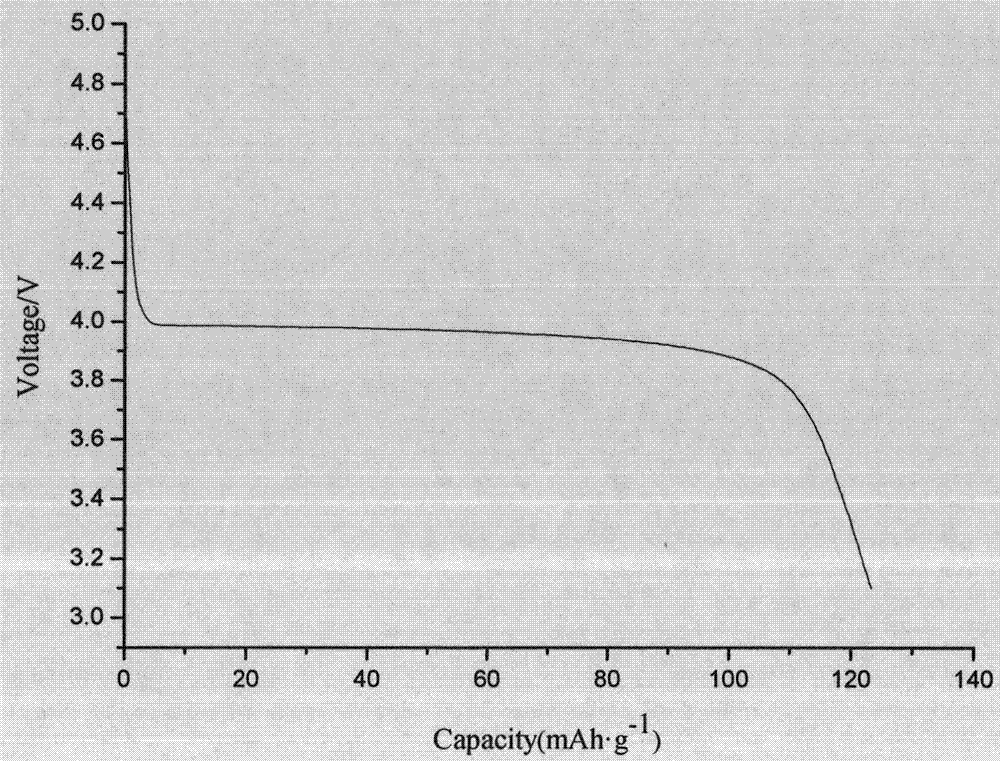

[0034] The composite material prepared by the above method was used to ...

Embodiment 2

[0037] 1) Weigh 0.1mol resorcinol, 0.2mol lithium oxalate, and 0.2mol ammonium dihydrogen phosphate to prepare a solution, add it to the solution prepared by 0.2mol acetaldehyde solution and 0.2mol manganese oxalate, add 0.002mol organic Catalyst tartaric acid. The mixed solution was stirred at a constant temperature of 70°C for 8 hours, and the pH value was adjusted to about 6.0 with ammonia water, and stirred until a gel was formed;

[0038] 2) The prepared gel was vacuum-dried at 140° C. for 3.5 hours, and the solvent was evaporated to obtain a dry gel; then, it was ball-milled on a planetary ball mill for 5 hours at a speed of 700 r / min. After fully grinding, it is calcined at 650°C for 11 hours under the protection of reducing atmosphere, and the gas flow rate is 0.1-10L / min. After cooling down to room temperature, LiMnPO coated with carbon airgel can be obtained. 4 / C Composite.

[0039] Electrodes were fabricated according to the method steps in Example 1, and batter...

Embodiment 3

[0041]1) Weigh 0.04mol catechol, 0.1mol lithium carbonate, and 0.2mol ammonium dihydrogen phosphate, prepare a solution, add to the solution prepared by 0.08mol formaldehyde solution and 0.2mol manganese sulfate, add 0.0002mol organic catalyst DL-malic acid. Stir the mixed solution at a constant temperature of 65°C for 14 hours, adjust the pH value to about 6.5 with ammonia water, and stir until a gel is formed;

[0042] 2) The obtained gel was vacuum-dried at 150° C. for 3 hours, and then the solvent was evaporated to obtain a dry gel; then, it was ball-milled on a planetary ball mill for 10 hours at a speed of 400 r / min. After fully grinding, it is calcined at 750°C for 8 hours under the protection of reducing atmosphere, and the gas flow rate is 0.1-10L / min. After cooling down to room temperature, LiMnPO coated with carbon airgel can be obtained. 4 / C Composite.

[0043] Electrodes were manufactured according to the method steps in Example 1, and battery assembly and cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com