Method for controlling a spark-ignition direct-injection internal combustion engine at low loads

A spark ignition and injection technology, applied in spark ignition controllers, internal combustion piston engines, electrical control, etc., can solve problems such as increasing combustion instability and reducing fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

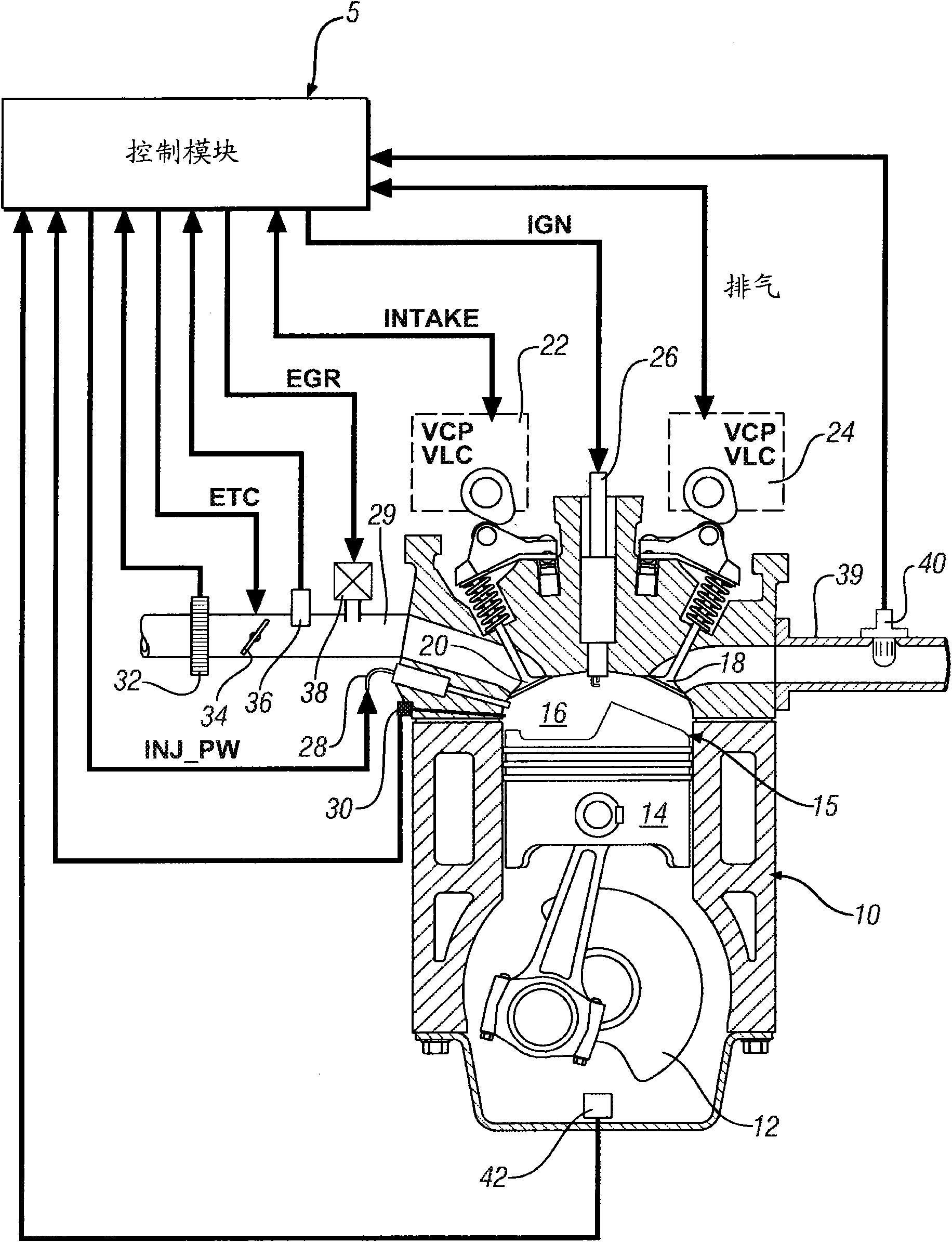

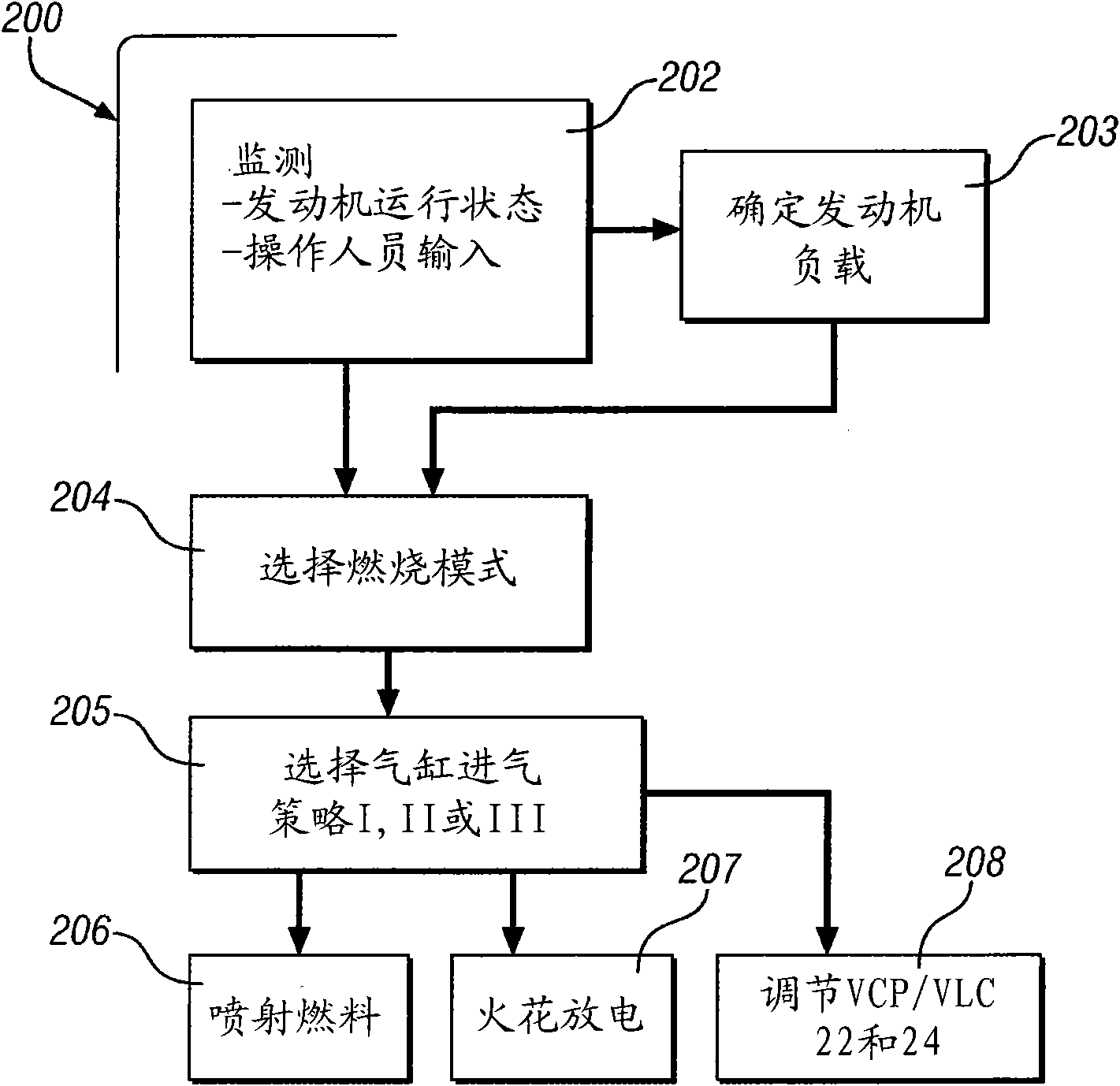

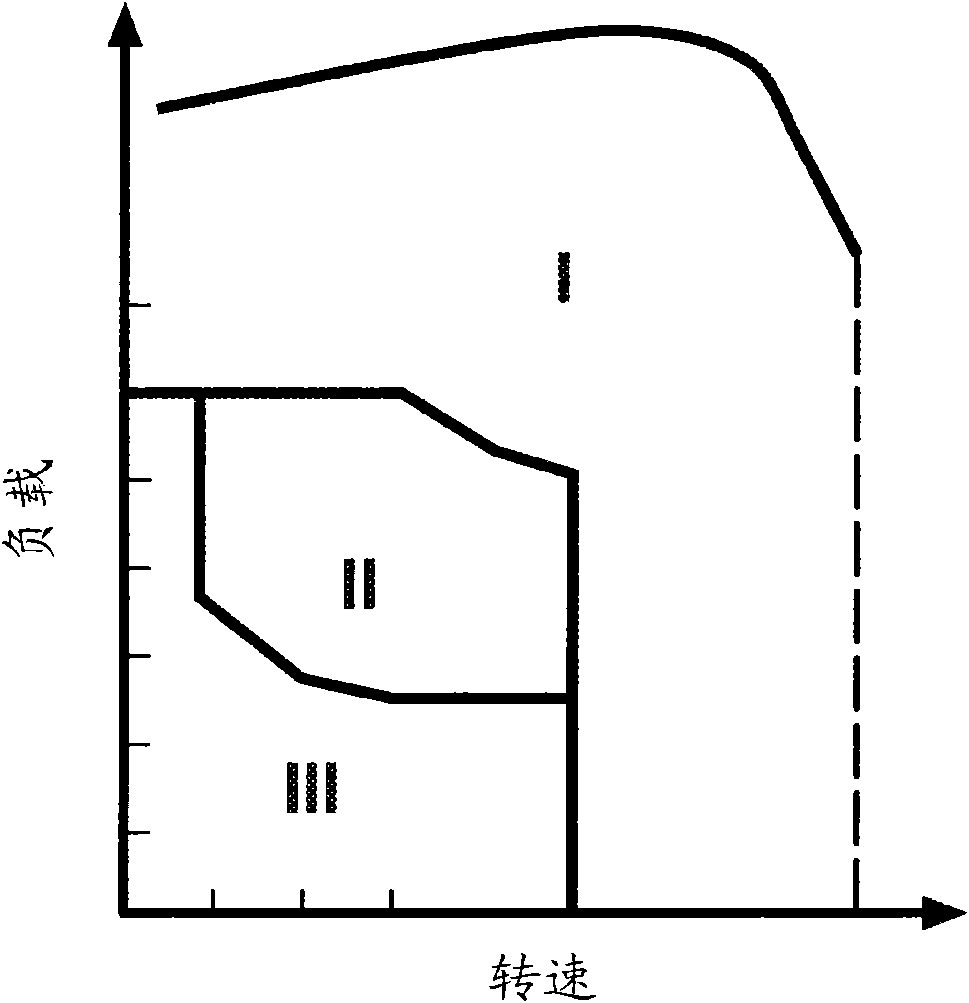

[0069] Referring now to the drawings, the illustrations therein are for illustration of certain exemplary embodiments only and are not intended to limit the invention. figure 1 An internal combustion engine 10 constructed in accordance with an embodiment of the present disclosure and associated control module 5 is schematically shown. Engine 10 is selectively operable in a variety of combustion modes, including a controlled auto-ignition combustion mode, a homogeneous spark-ignition combustion mode, and a stratified spark-ignition combustion mode. Engine 10 is selectively operated at a stoichiometric air / fuel ratio and at a stoichiometric predominantly lean air / fuel ratio. The present disclosure can be applied to various internal combustion engine systems and combustion cycles.

[0070] In one embodiment, engine 10 may be connected to a transmission arrangement (not shown) for transmitting tractive power to a powertrain (not shown) of a motor vehicle. The transmission, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com