Polycation additive for reducing phenols in cigarette smoke and preparation method

A cigarette smoke and additive technology, applied in the field of polycation additives and its preparation, can solve the problems of increasing harmful components, complicated preparation process, and influence on the taste of smoke, so as to reduce the harmful components of phenols, avoid the loss of flavor components, and maintain Intrinsic Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Dissolve polyglucosamine acrylate hydrochloride in water to prepare a 0.5mg / mL polycation solution, then immerse 5.0g powdered silica gel into 15ml of the above polycation solution, soak for 4 hours, filter, and dry the obtained solid at 60°C After 12 hours, the additive was obtained, and the weight percentage of polycation loaded in the additive was 0.8%. Through infrared spectrum characterization analysis, the infrared spectrum of the additive is 3000~3100cm -1 、1740cm -1 and 1000~1100cm -1 The appearance of three characteristic peaks verified that the polyglucosamine acrylate hydrochloride was successfully loaded on the powdered silica gel, and a granular porous material loaded with polyglucosamine acrylate hydrochloride was obtained.

[0032] After testing, the particle size of the additive is 0.3mm, and the specific surface area is 750m 2 / g, the mass moisture content is 15%.

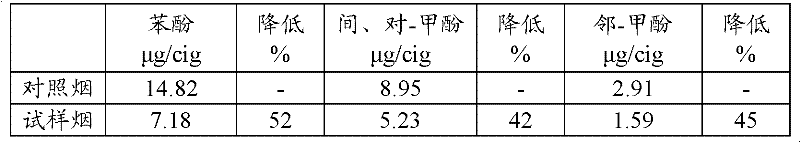

[0033] The above-mentioned additives are evenly added to the loosened cellulose aceta...

Embodiment 2

[0038] Dissolve polyglucosamine acrylate hydrochloride in water to prepare a 3mg / mL polycation solution, then immerse 5.0g of granular diatomaceous earth into 20ml of the above polycation solution, soak for 3h, filter, and the obtained solid is placed at 60°C Bake for 12 hours to obtain the additive, and the mass percentage of the polycation loaded in the additive is 0.5%. Through infrared spectrum characterization analysis, the infrared spectrum of the additive is 3000~3100cm -1 、1740cm -1 and 1000~1100cm -1 The appearance of three characteristic peaks verified that the polyglucosamine acrylate hydrochloride was successfully loaded on the granular diatomite, and a granular porous material loaded with polyglucosamine acrylate hydrochloride was obtained.

[0039] After testing, the particle size of the additive is 0.1mm, and the specific surface area is 750m 2 / g, the mass moisture content is 20%.

[0040] The above-mentioned additives are rolled and formed on a filter rod ...

Embodiment 3

[0045] Dissolve polyglucosamine acrylate hydrochloride in water to prepare a 1mg / mL polycation solution, then immerse 5.0g granular molecular sieves in 15ml of the above polycation solution, soak for 3h, filter, and dry the obtained solid at 60°C for 12h , to obtain the additive, and the mass percentage of the polycation loaded in the additive is 0.3%. Through infrared spectrum characterization analysis, the infrared spectrum of the additive is 3000~3100cm -1 、1740cm -1 and 1000~1100cm -1 The appearance of three characteristic peaks verified that polyglucosamine acrylate hydrochloride was successfully loaded on the granular molecular sieve, and a granular porous material loaded with polyglucosamine acrylate hydrochloride was obtained.

[0046] After testing, the particle size of the additive is 0.5mm, and the specific surface area is 250m 2 / g, the mass moisture content is 25%.

[0047] The above-mentioned additives are evenly added to the loosened cellulose acetate tow on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com