Steel dental plate crusher and manufacture method thereof

A technology of pulverizer and steel tooth plate, which is applied in the direction of grain processing, etc., can solve the problems of no cutting function, breakage, and low production efficiency, and achieve the effects of reducing raw material and power consumption, prolonging service life, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

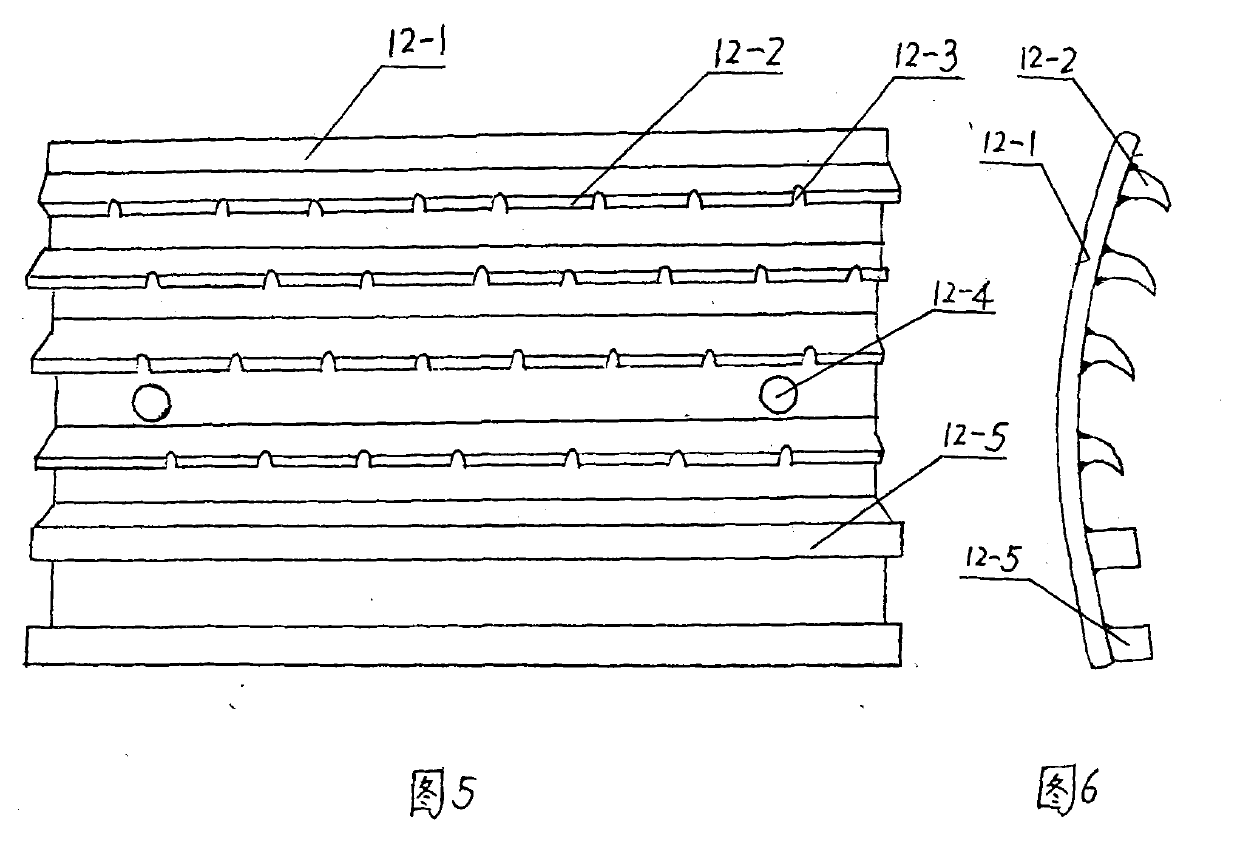

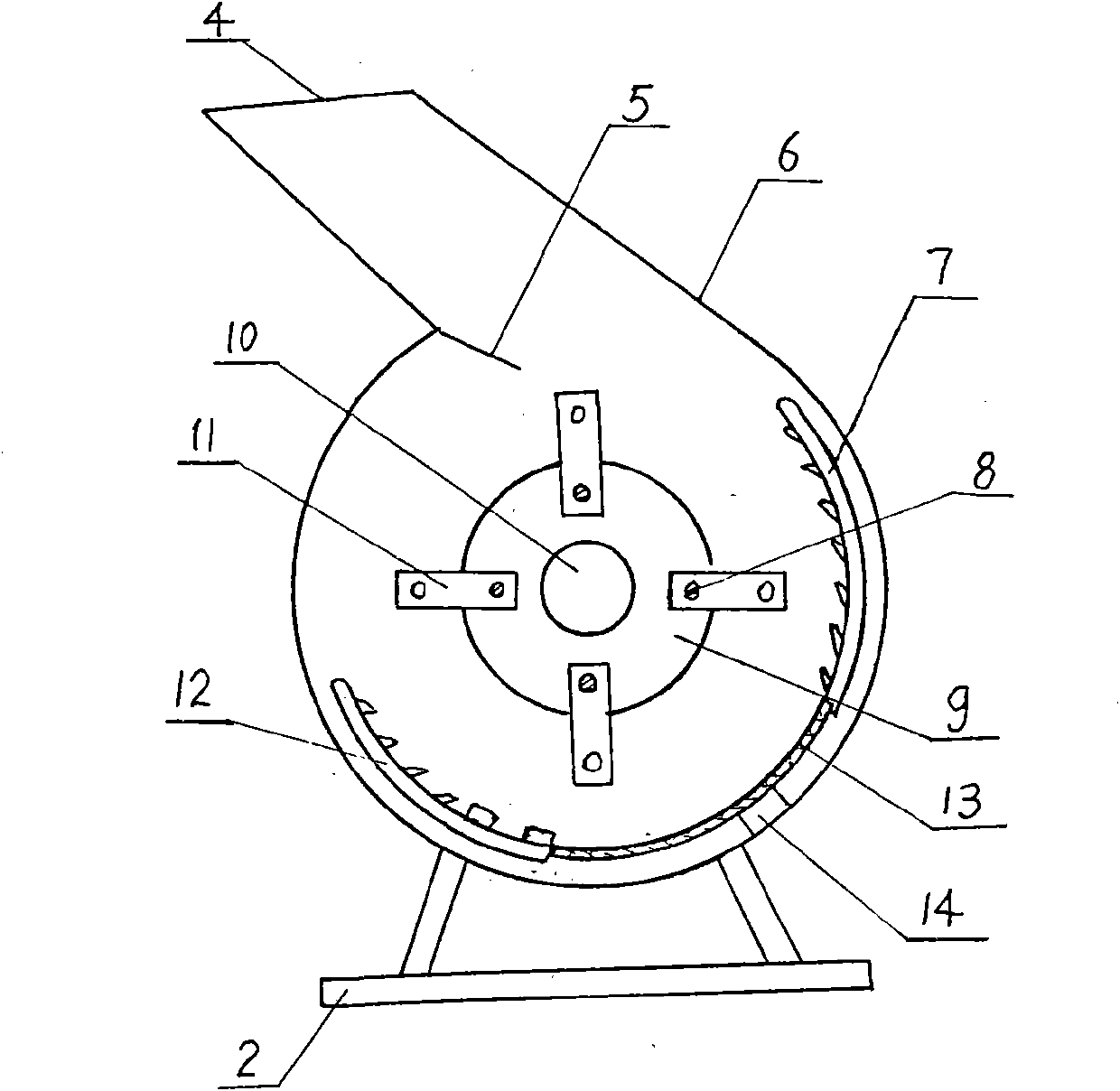

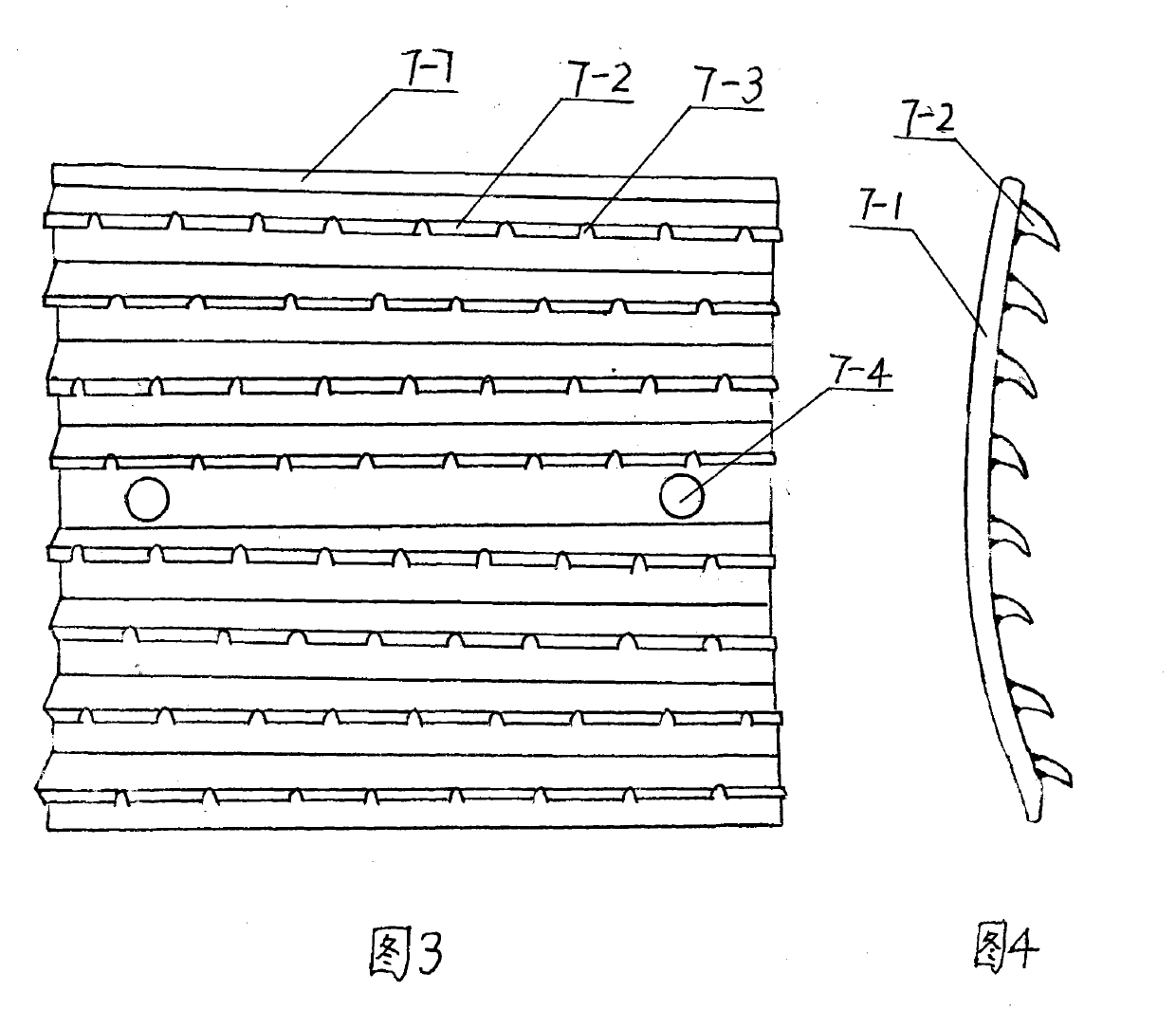

Embodiment 1

[0030] The manufacture method of this pulverizer is to carry out as follows:

[0031] 1) The main tooth plate blank and the auxiliary tooth plate blank are produced by welding and forming: according to the set process requirements, the low carbon steel plate is taken to intercept the arc-shaped substrate blank, the fixed blade blank and the grinding bar blank respectively, and the arc The arc-shaped base plate blanks are respectively rolled and formed, and are welded together with the fixed blade blanks and the grinding rod blanks. Among them, the thickness of the plate used for the fixed blade blanks is 2mm, and the main tooth plate blanks and auxiliary tooth plate blanks are made. And complete the processing of the mounting holes;

[0032] 2) Manufacturing of pin shaft blanks and movable blade blanks: According to the set process, the pin shaft blanks and movable blade blanks are blanked and processed for later use, and the thickness of the plate used for the movable blades ...

Embodiment 2

[0038] The manufacturing method of the pulverizer of this embodiment is basically the same as that of Example 1, the only difference being: in step 1), the thickness of the plate used for the fixed blade blank is 3 mm; in step 2), the thickness of the plate used for the movable blade is 3 mm; step 3 ), the carburized thickness is 1.2mm.

Embodiment 3

[0040]The manufacturing method of the pulverizer in this embodiment is basically the same as that in Example 1, the only difference is that in step 1), the main tooth plate blank and the auxiliary tooth plate blank are made by casting, and the method is: according to conventional pressure casting or precision casting The process method is to cast the main tooth plate blank and the auxiliary tooth plate blank respectively, and complete the processing of the mounting holes, wherein the casting thickness of the fixed blade is 4mm. In step 2), the thickness of the plate used for the movable blade is 4mm; in step 3) , Carburizing thickness is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com