Flexible longitudinal driving mechanism positioning device

A driving mechanism and positioning device technology, applied in auxiliary devices, gas flame welding equipment, plasma welding equipment, etc., to achieve the effect of comprehensive precision assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

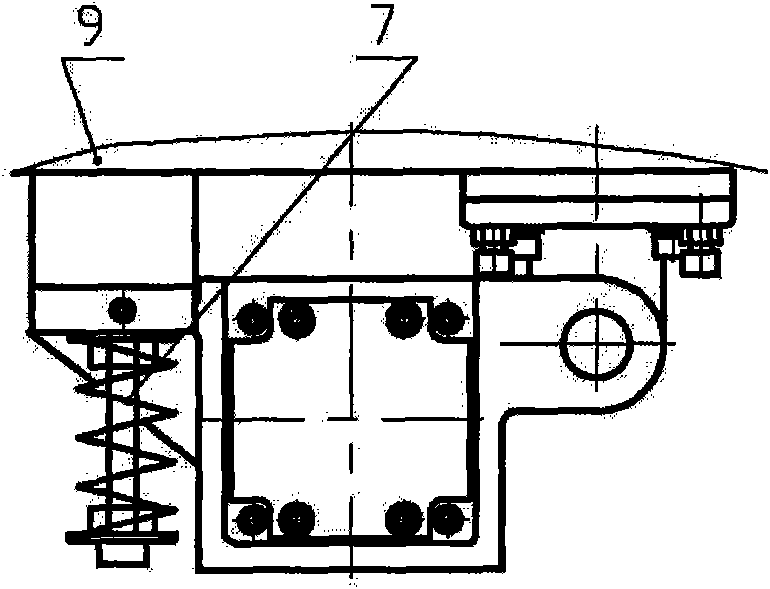

[0015] combine image 3 and Figure 4 , the positioning device for the flexible longitudinal drive mechanism proposed by the present invention includes an adjustment seat 8, whose upper and lower surfaces are all positioned with copper top wires 12, and the upper and lower top wire holes are respectively made on the upper and lower surfaces of the adjustment seat 8. The adjustment seat 8 is fixed on the large longitudinal frame 9 by the hexagon socket head cap screws. After the longitudinal gear 5 and the rack 10 of the machine are meshed to an optimal state, adjust the copper top wire 12 on the top and bottom of the adjustment seat 8 to compress the spring. There is no play gap between the top and bottom of the end 7, thereby ensuring that the gear 5 can move smoothly when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com