Multifunctional fully-automatic screw conveyer

A fully automatic and multi-functional technology, applied to screwdrivers, motor tools, wrench, etc., can solve the problems of low work efficiency, slow speed, waste of manpower, etc., and achieve the effects of cost saving, small size, and simplified troubleshooting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

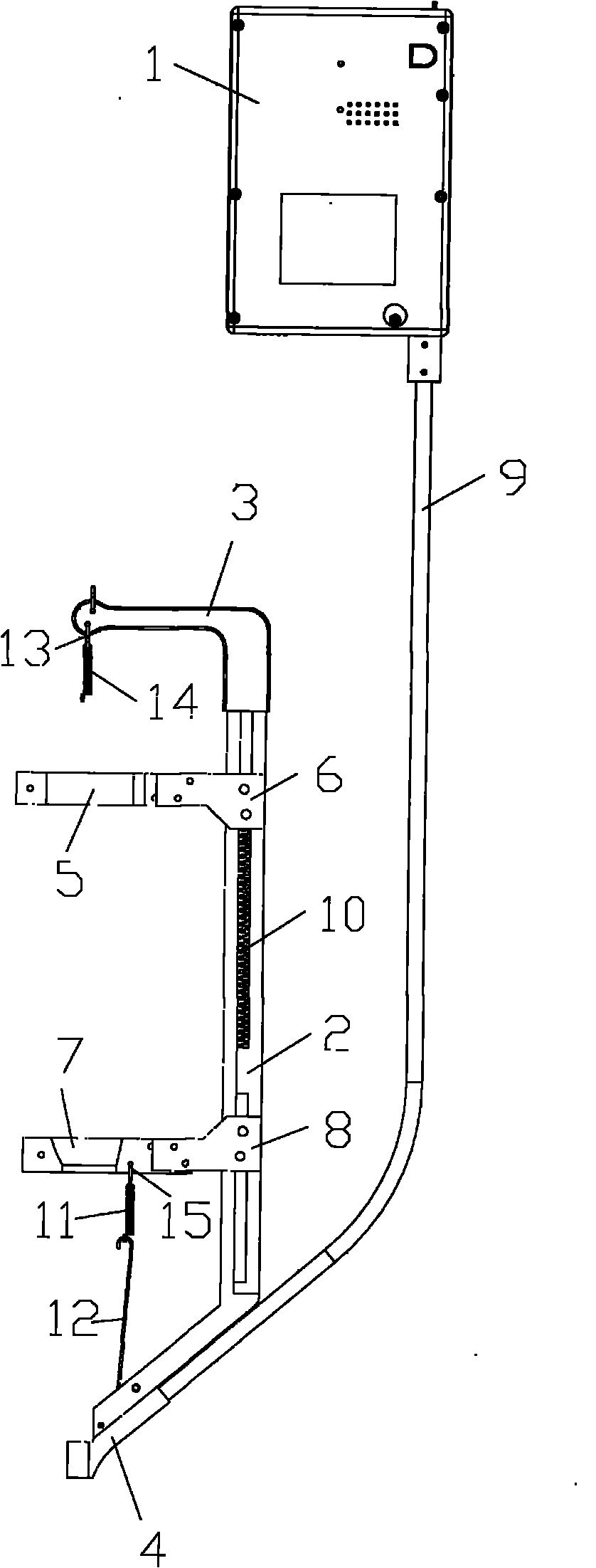

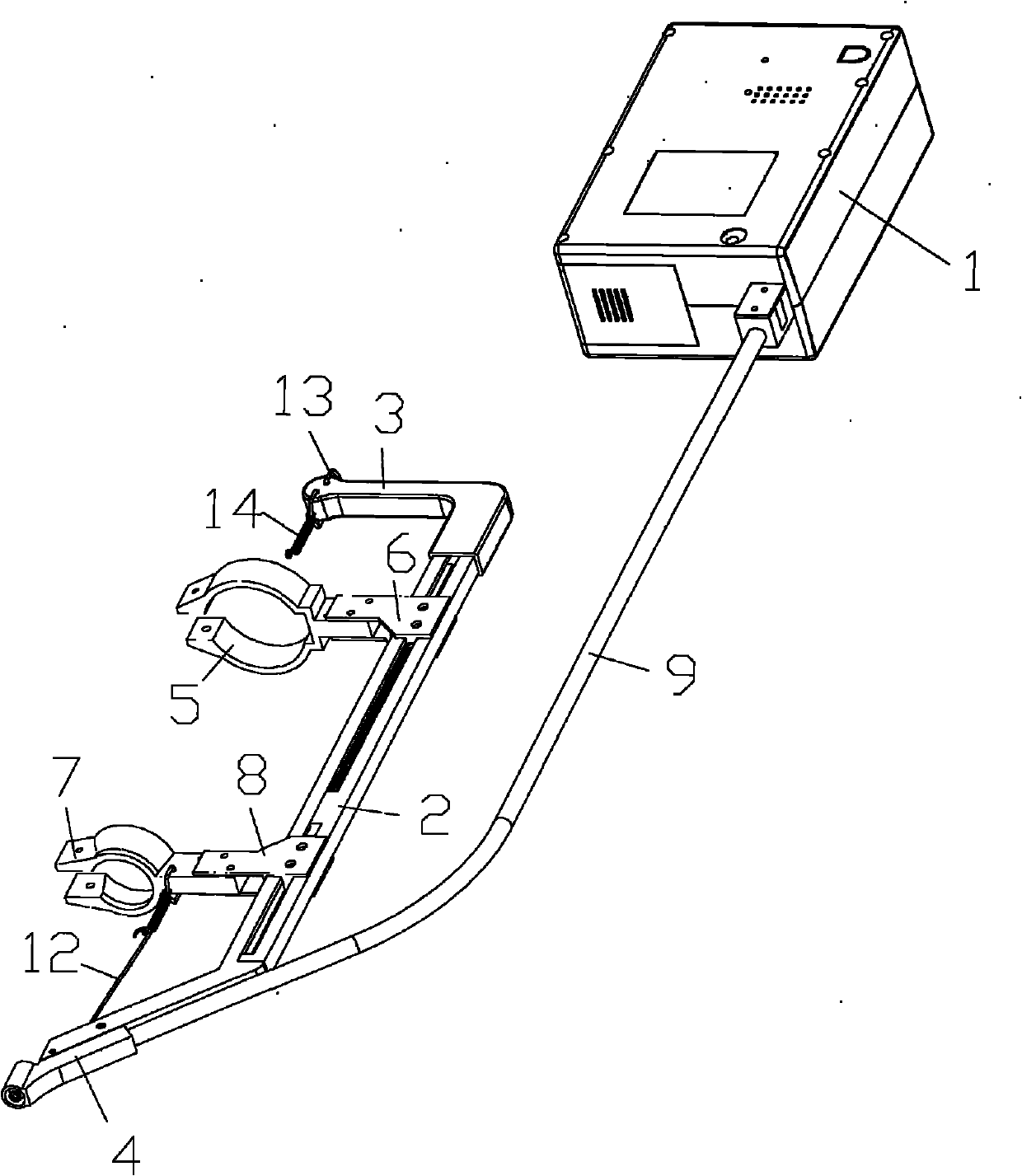

[0028] Examples, see attached Figure 1~3 ;Multi-functional automatic screw conveyor, including the main box 1 and the sliding frame 2, the upper end of the sliding frame is screwed to fix the right-angle bracket 3, the lower end is screwed to the batch mouth position limit structure 4, and the upper firmware 5 passes through the upper connecting plate 6 It is fixedly connected with the sliding frame, the lower firmware 7 is fixedly connected with the sliding frame through the lower connecting plate 8, one end of a flexible pipe 9 is connected with the main chassis, and the other end is connected with the position limiting structure 4 of the batch mouth.

[0029] A spring 10 is installed in the sliding frame 2, and the spring is located between the upper and lower connecting plates.

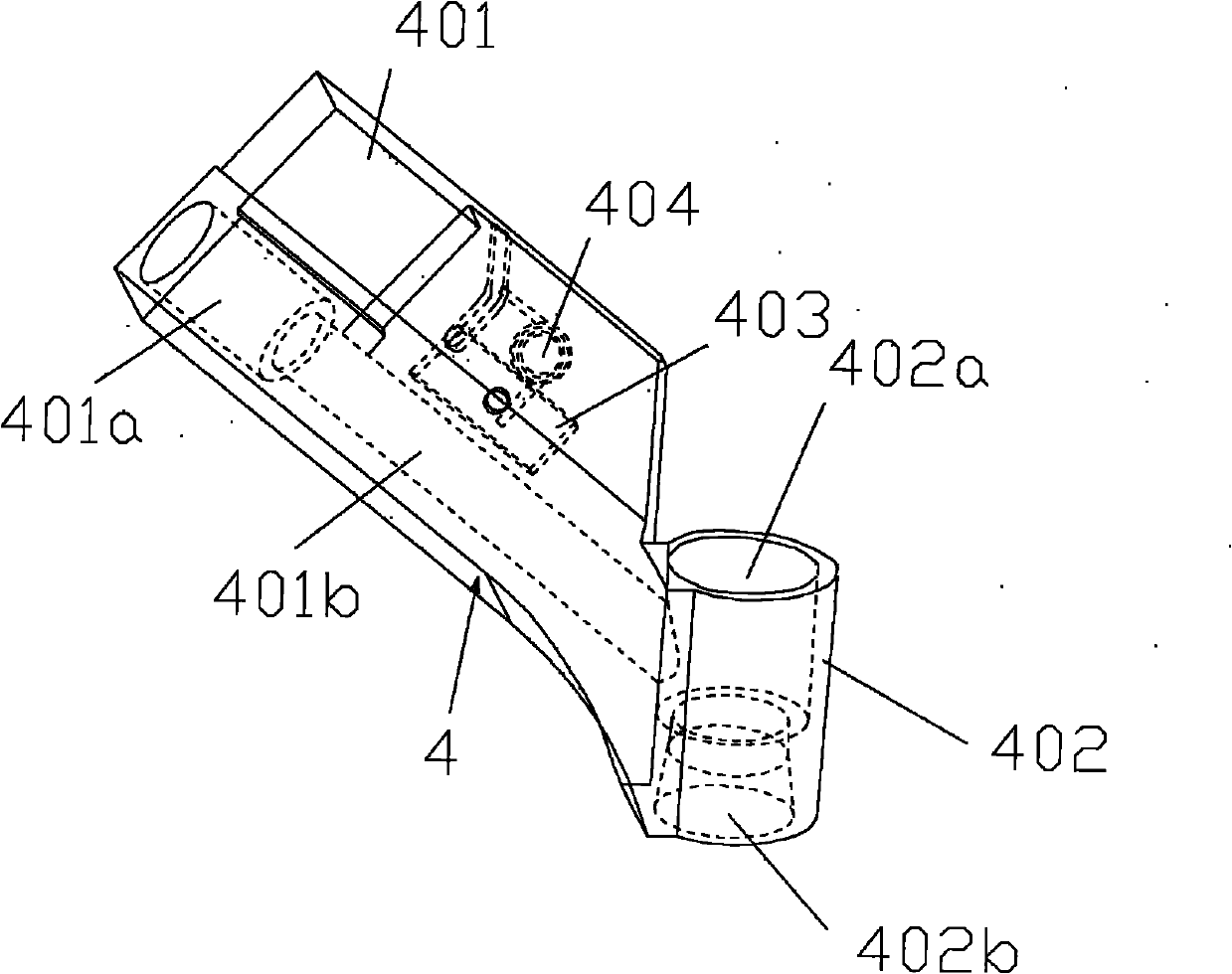

[0030] The mouth position limiting structure 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com