Direction indicator light mounting structure for engine driven cart

A technology for direction indicators and motorized two-wheeled vehicles, applied to bicycle accessories, transportation and packaging, optical signals, etc., can solve the problems of reduced rigidity, detachment of the cage, and increased shaking of the direction indicators, so as to improve rigidity and prevent Effects of shaking and shortening the path length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

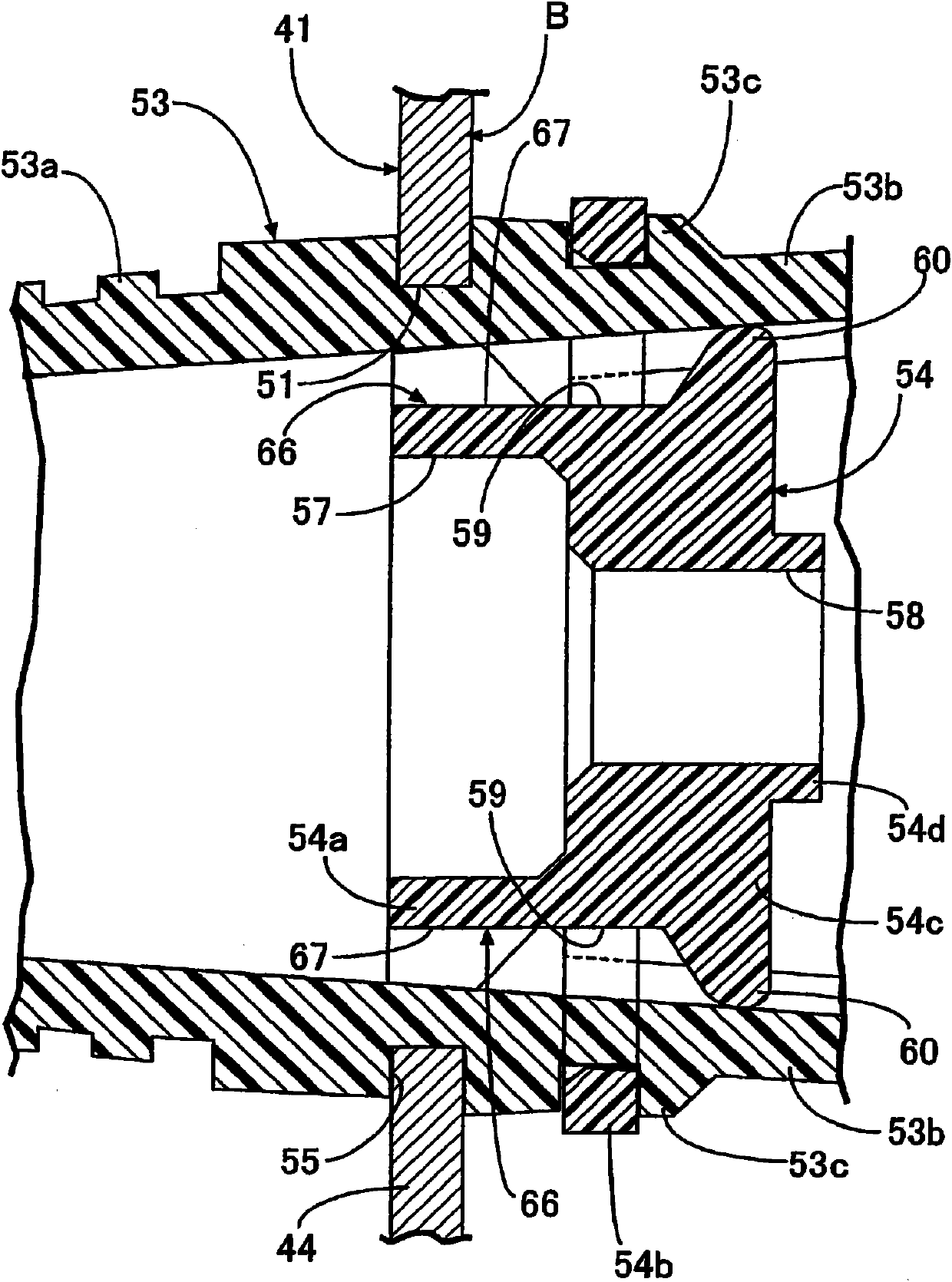

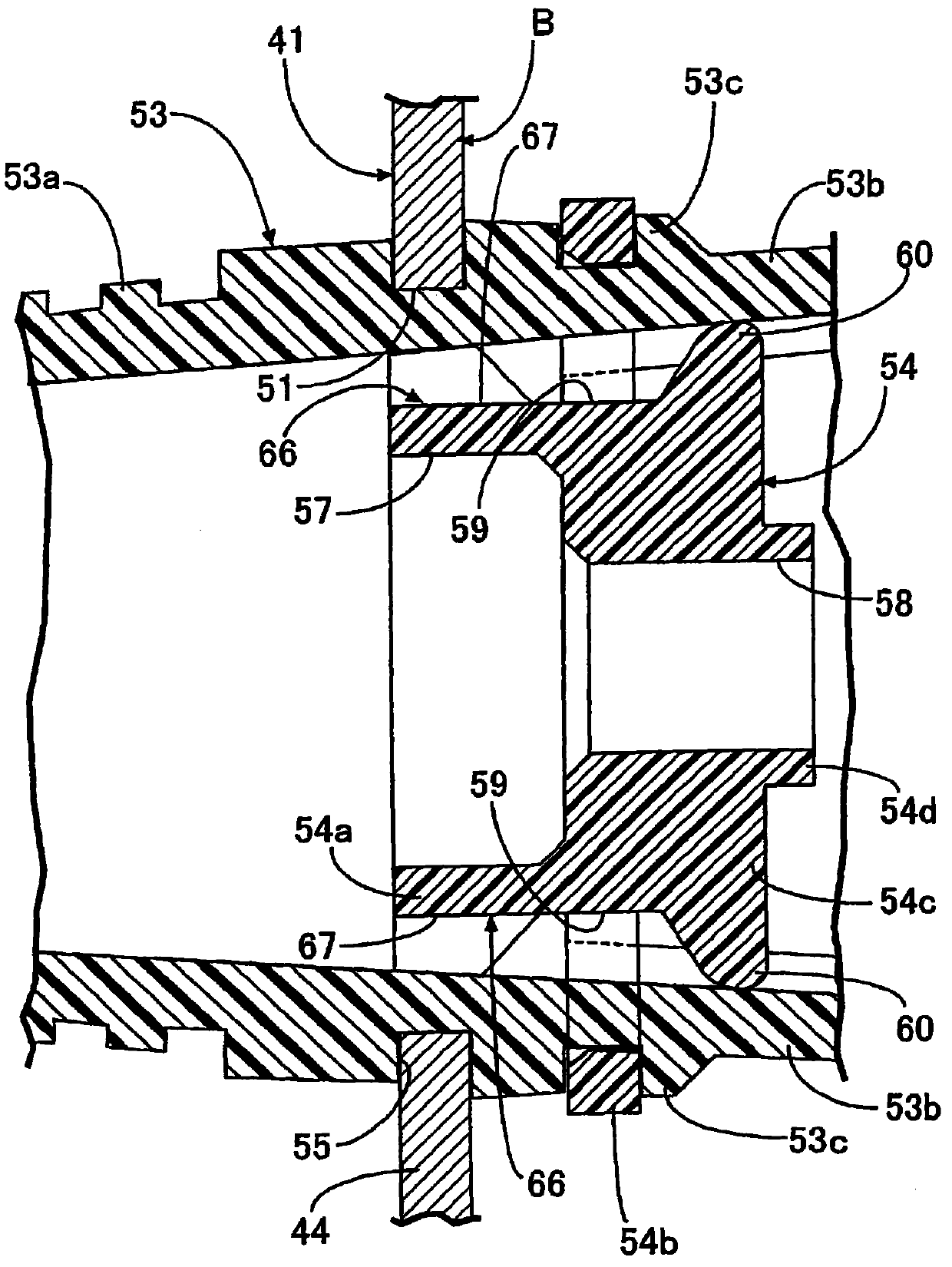

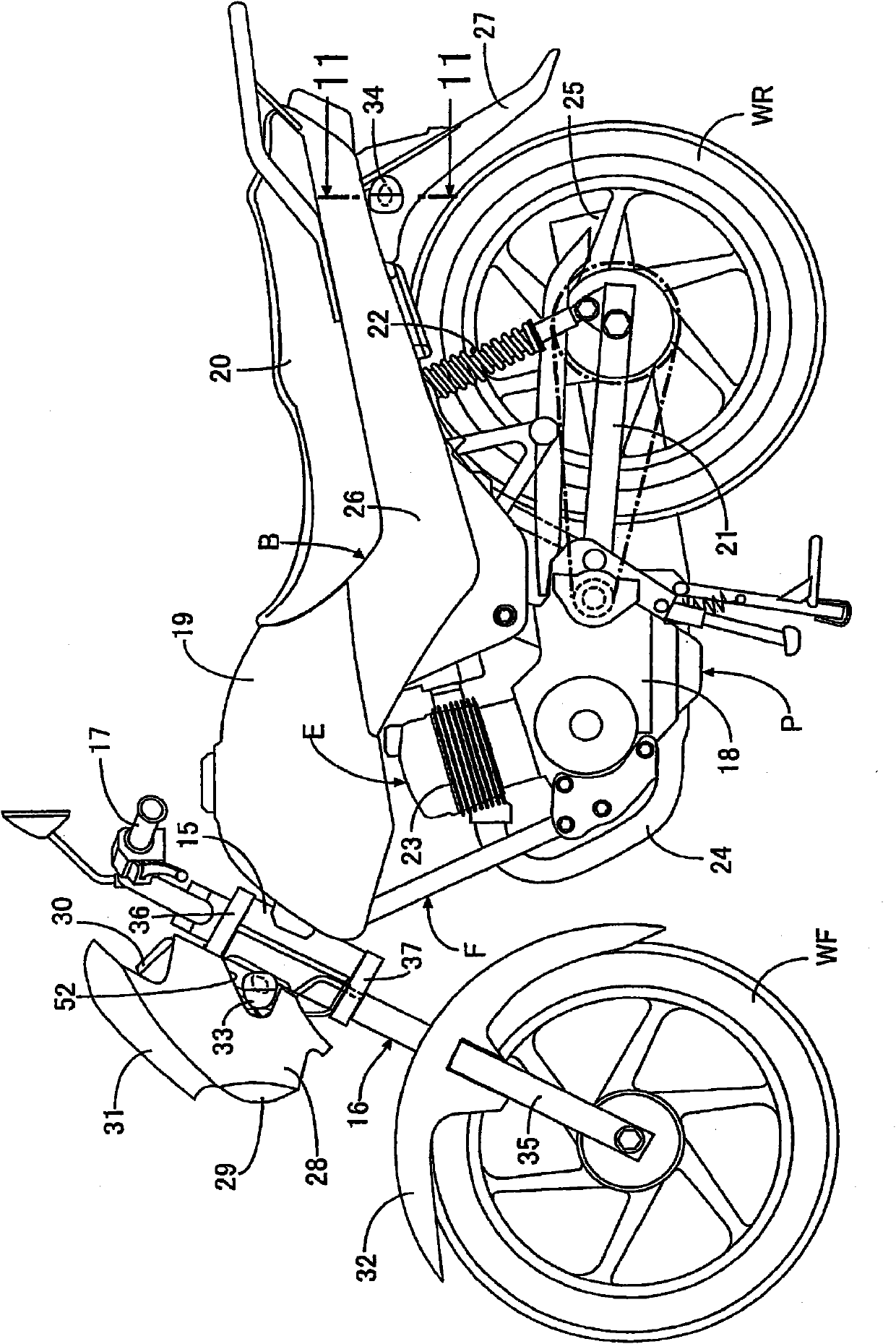

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0045] refer to Figure 1 to Figure 12 , to describe the embodiment of the present invention, first, in figure 1 Among them, a front fork 16 and a steering handle 17 are supported on the head pipe 15 provided at the front end of the body frame F of the motorcycle. The front fork 16 pivotally supports the front wheel WF. The steering handle 17 can be steered. Behind the head pipe 15 , an engine body 18 of an engine E is mounted on the body frame F, and a power unit P is constituted by the engine E and a transmission (not shown) built in the engine body 18 . Above the power unit P, a fuel tank 19 is mounted on a body frame F, and a passenger seat 20 arranged behind the fuel tank 19 is supported by the rear portion of the body frame F. As shown in FIG.

[0046] Behind the power unit P, the front end of the swing arm 21 is supported by the body frame F so that the swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com