Plate roller clamping device, desk type plate roller loading/unloading equipment and plate roller hoisting automation equipment

A clamping device and plate roller technology, applied in the preparation, printing, cells and other directions of the printing surface, can solve the problems of high labor intensity and low production efficiency, improve production efficiency, reduce collision, improve safety and reliability and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

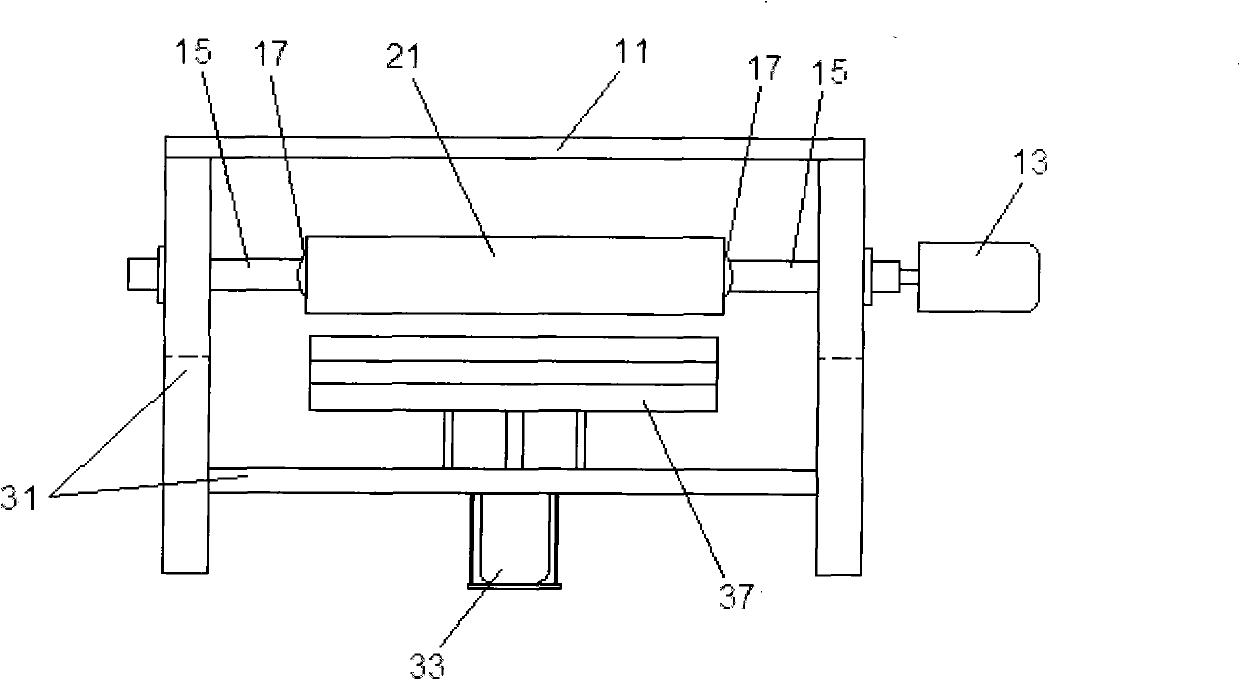

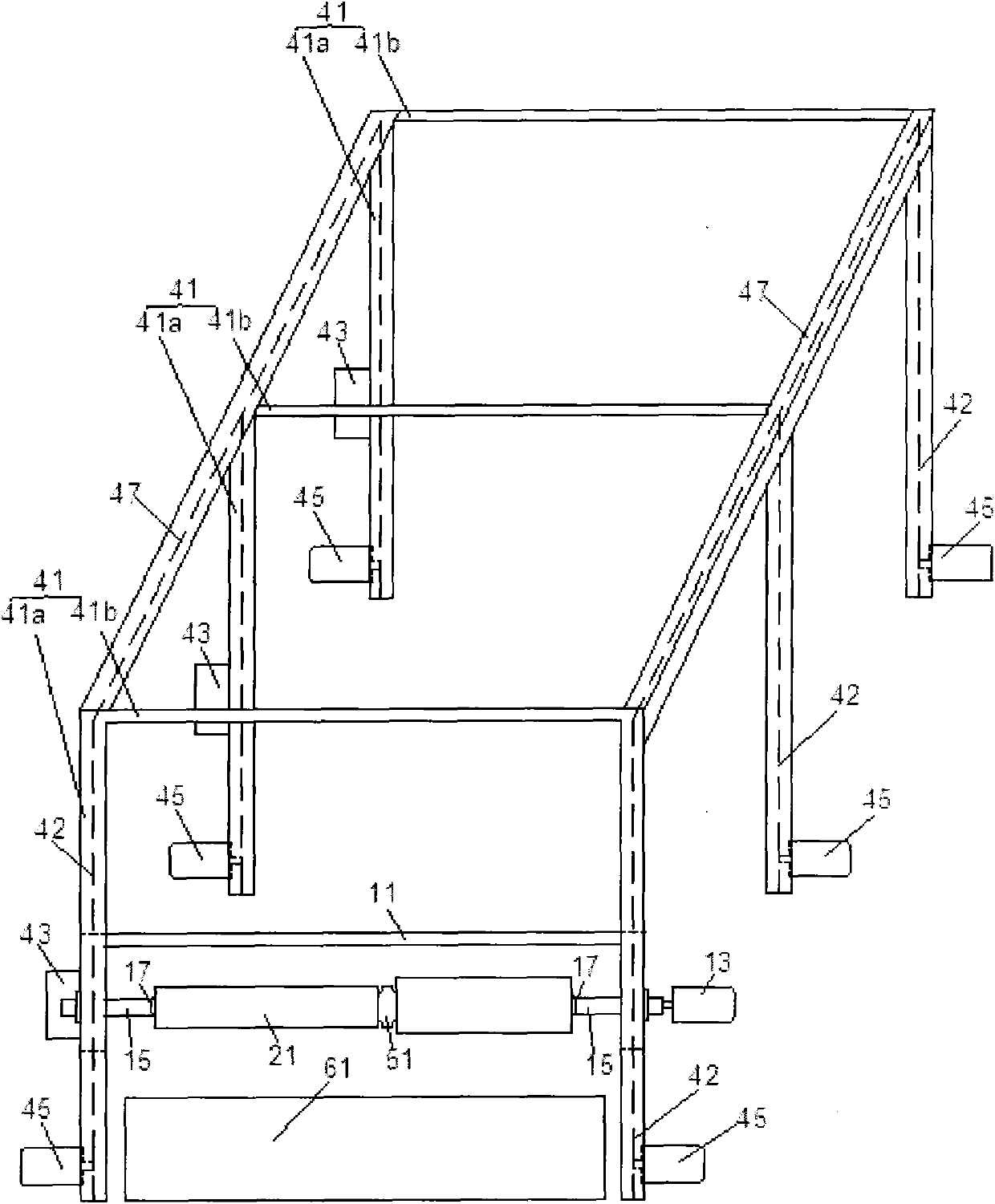

[0016] see figure 1 , a clamping device for moving a plate roll with a center hole at both ends, comprising a clamping bracket 11, a driving device 13, a pair of ejector rods 15 and a flexible sealing pad 17, and the clamping bracket 11 includes a cross bar 11a A vertical bar 11b protrudes from both ends of the cross bar 11a; the push rod 15 is driven by the driving device 13 to move axially along the cross bar 11a and is respectively installed on the vertical bars 11b at the two ends of the cross bar 11a, It is used to withstand the two ends of the plate roller 21 in the axial direction; the driving device 13 is a motor, and the motor is used to lock the ejector rod 15, which has high safety and reliability and is easy to operate; the flexible sealing gasket 17 is fixedly installed with the ejector rod The top of the cylinder is used to seal the central hole of the version roller 17. Since the two ends of the clamping bracket 11 are equipped with a pair of ejector rods 15 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com