Anti-scaling and anti-sand device connected with oil pumping tubing string into whole and application method

A technology for oil extraction strings and oil extraction pipes, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve problems such as piston and pump barrel stuck, pump stuck, failure, etc., to avoid pump leakage and prolong The effect of checking the pump cycle and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

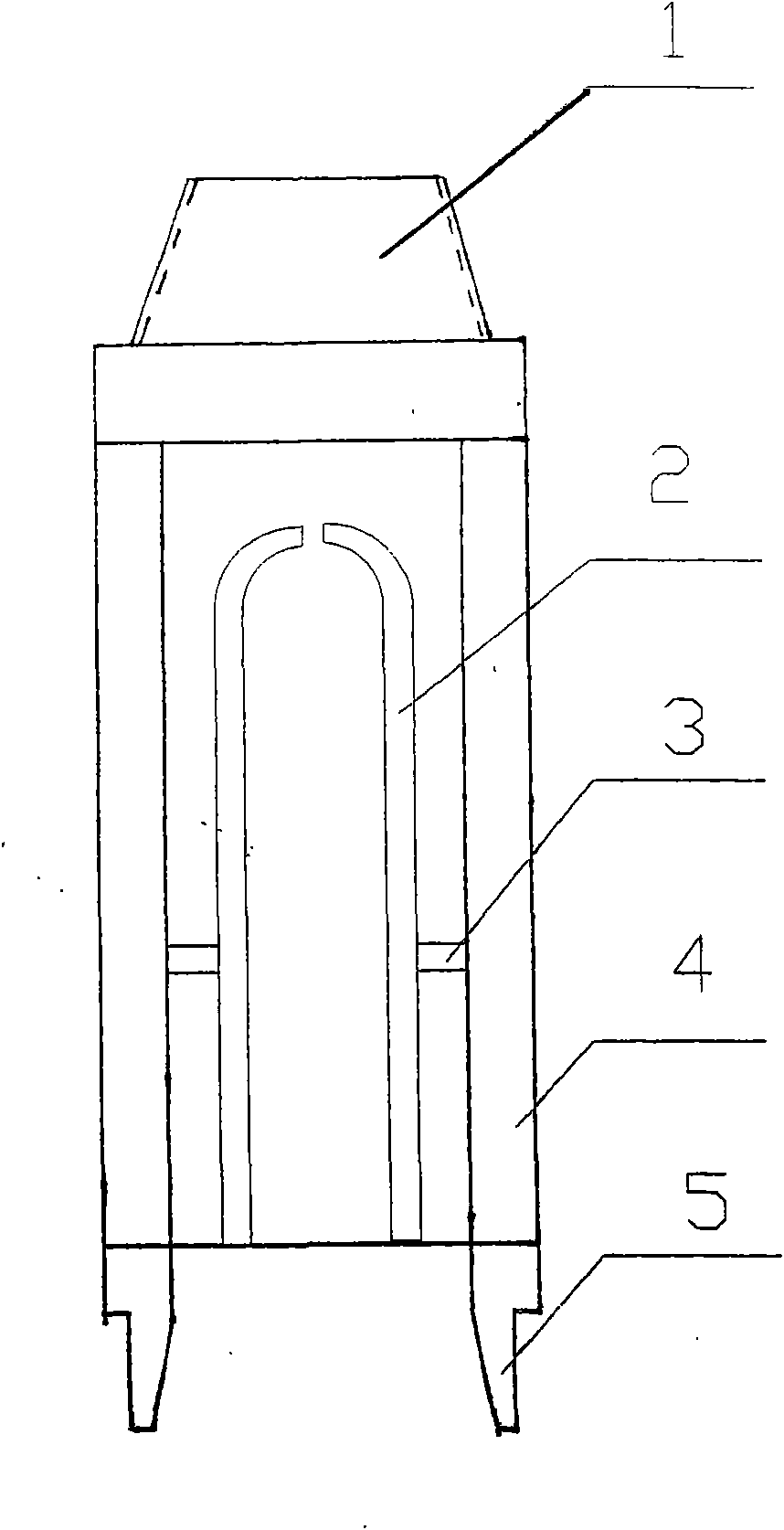

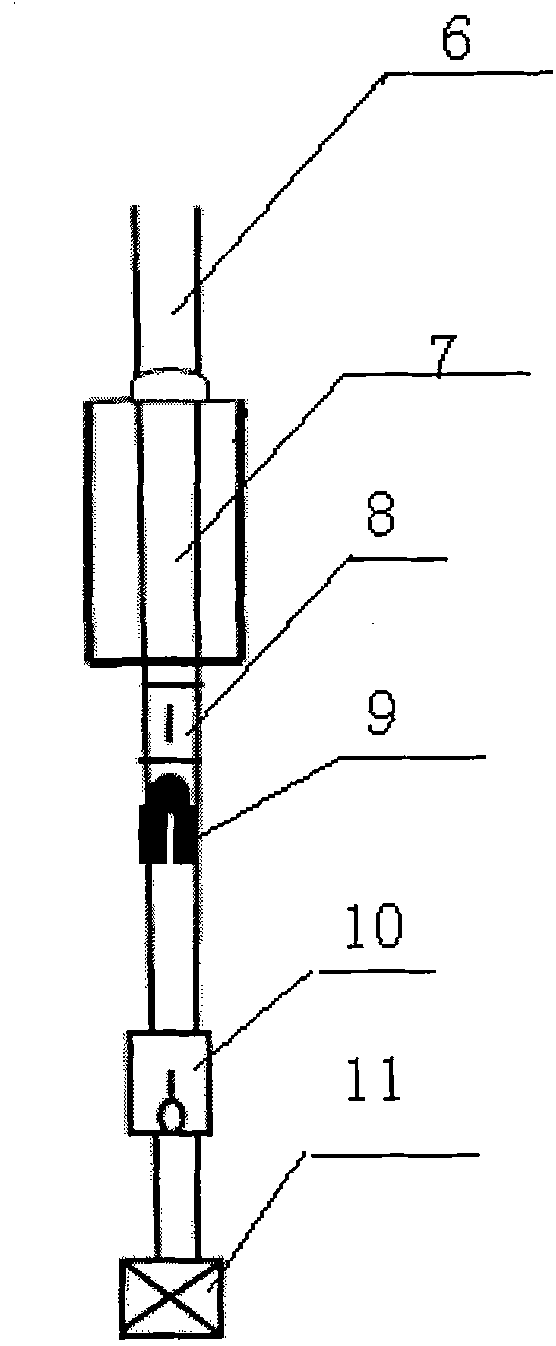

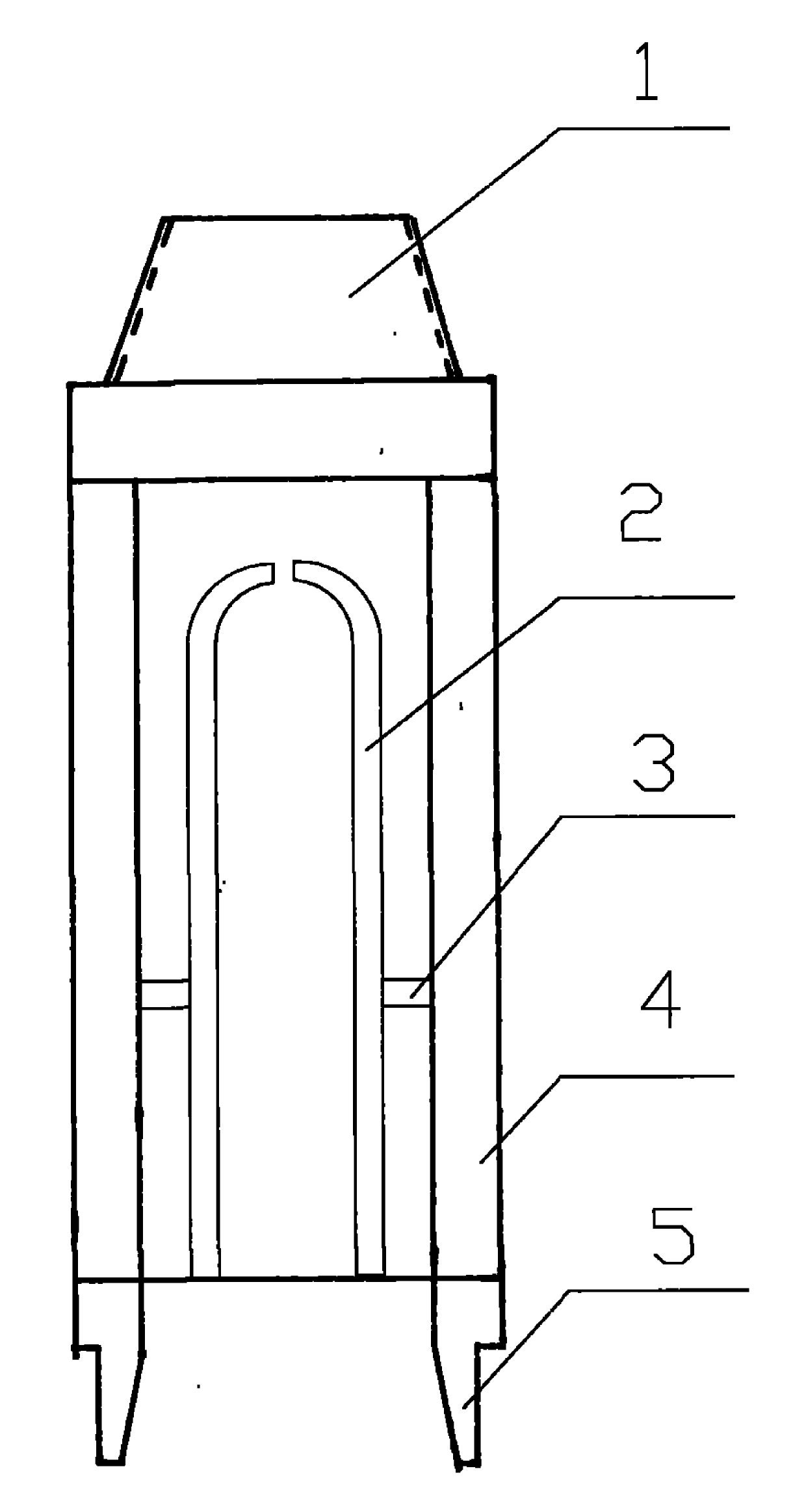

[0029] refer to figure 1 , figure 2 As shown, an anti-scale and sand control device connected with the oil extraction string as a whole, the device includes an oil extraction pipe 6, an oil well pump 9, an air anchor 10, and a plug 11. One end is connected, the other end of the anti-scaling and sand control device 7 is connected to one end of the tubing nipple 8, the other end of the tubing nipple 8 is connected to the oil well pump 9, one end of the outer pipe of the oil well pump 9 is connected to the air anchor 10, and one end of the outer pipe of the air anchor 10 is connected Connected with the plug 11, one end of the upper joint 1 of the anti-scale and sand control device 7 is connected with the oil suction pipe 6 through a pipe collar, and the other end of the upper joint 1 is connected with the ring-shaped anti-scale cover 4, and the middle of the ring-shaped anti-scale cover 4 is inserted into the center Pipe 2, central pipe 2 external diameters are connected with r...

Embodiment 2

[0042] The annular gap between the inner wall and the outer wall of the annular anti-scaling cover is 22mm, and the length is 2400mm.

[0043] The diameter of the center pipe is φ60mm, and the gap between the center pipe and the ring-shaped anti-scaling cover is a sand setting space.

[0044] The length×diameter of the annular anti-fouling cover are 2400mm×114mm respectively.

[0045] The diameter of the tubing nipple is φ72mm and the length is 30mm.

[0046] The rated pressure of the anti-scaling and sand control device is at least 35Mpa, and the tensile force is at least 520KN. Said annular sand shield is rated for at least 160°C

[0047] Embodiment 2 is the same as Embodiment 1 except that the content described above is changed.

Embodiment 3

[0049] The annular gap between the inner wall and the outer wall of the annular anti-scaling cover is 25mm, and the length is 3600mm.

[0050] The diameter of the center pipe is φ70mm, and the gap between the center pipe and the ring-shaped anti-scaling cover is a sand setting space.

[0051] The length×diameter of the annular anti-fouling cover are 3600mm×114mm respectively.

[0052] The diameter of the tubing nipple is φ73mm and the length is 35mm.

[0053] The rated pressure of the anti-scaling and sand control device is at least 35Mpa, and the tensile force is at least 520KN.

[0054] Said annular sand shield has a rated temperature of at least 160°C.

[0055] Embodiment 3 is the same as Embodiment 1 except that the content described above is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com