Connection and transmission device of floating gear sleeve of gear baffle plate

A technology of transmission and floating teeth, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc. It can solve the problems of large bearing rings and steps for holes, poor floating effect of sun gears, etc., and achieve reliable connection , Simple structure, good transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

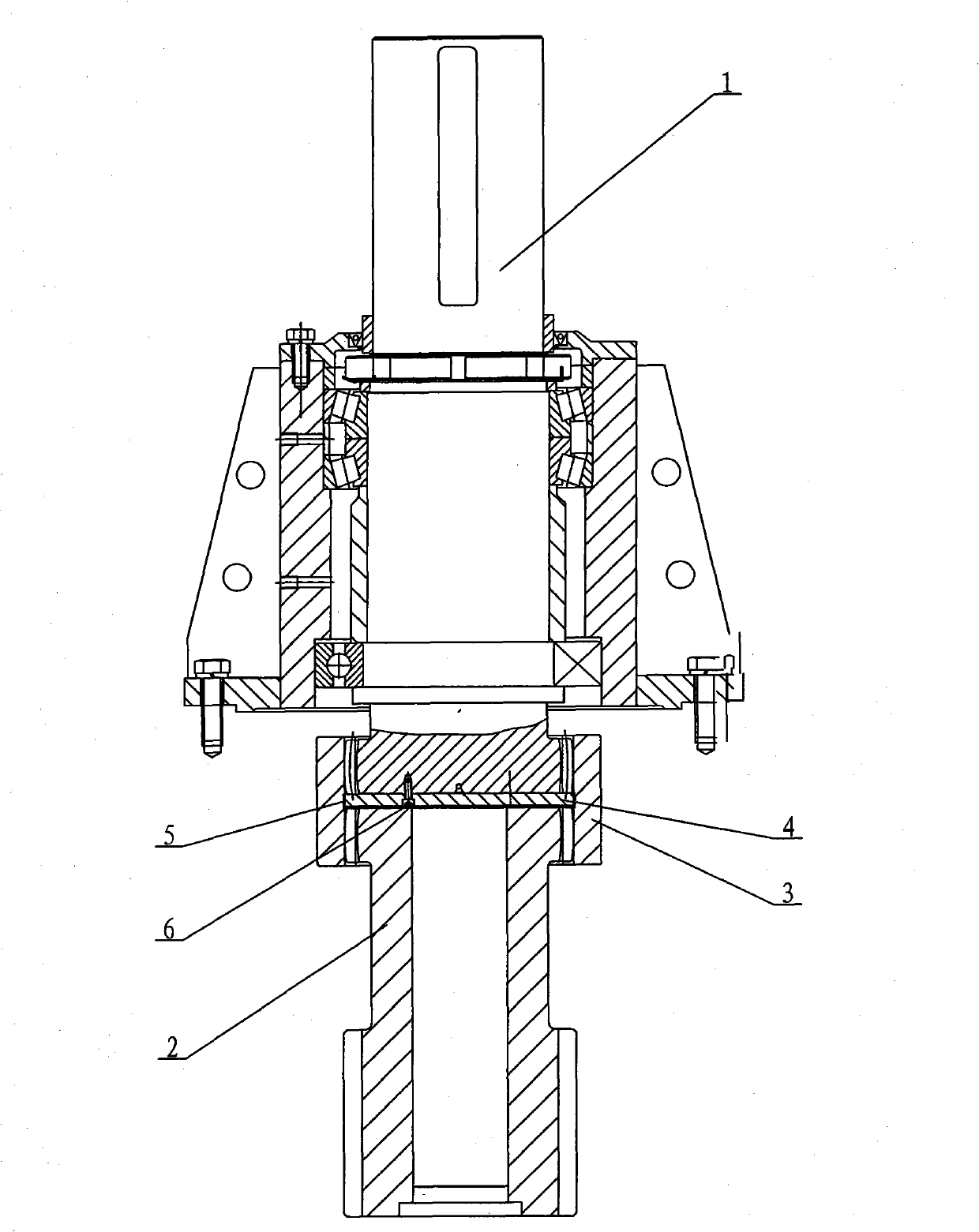

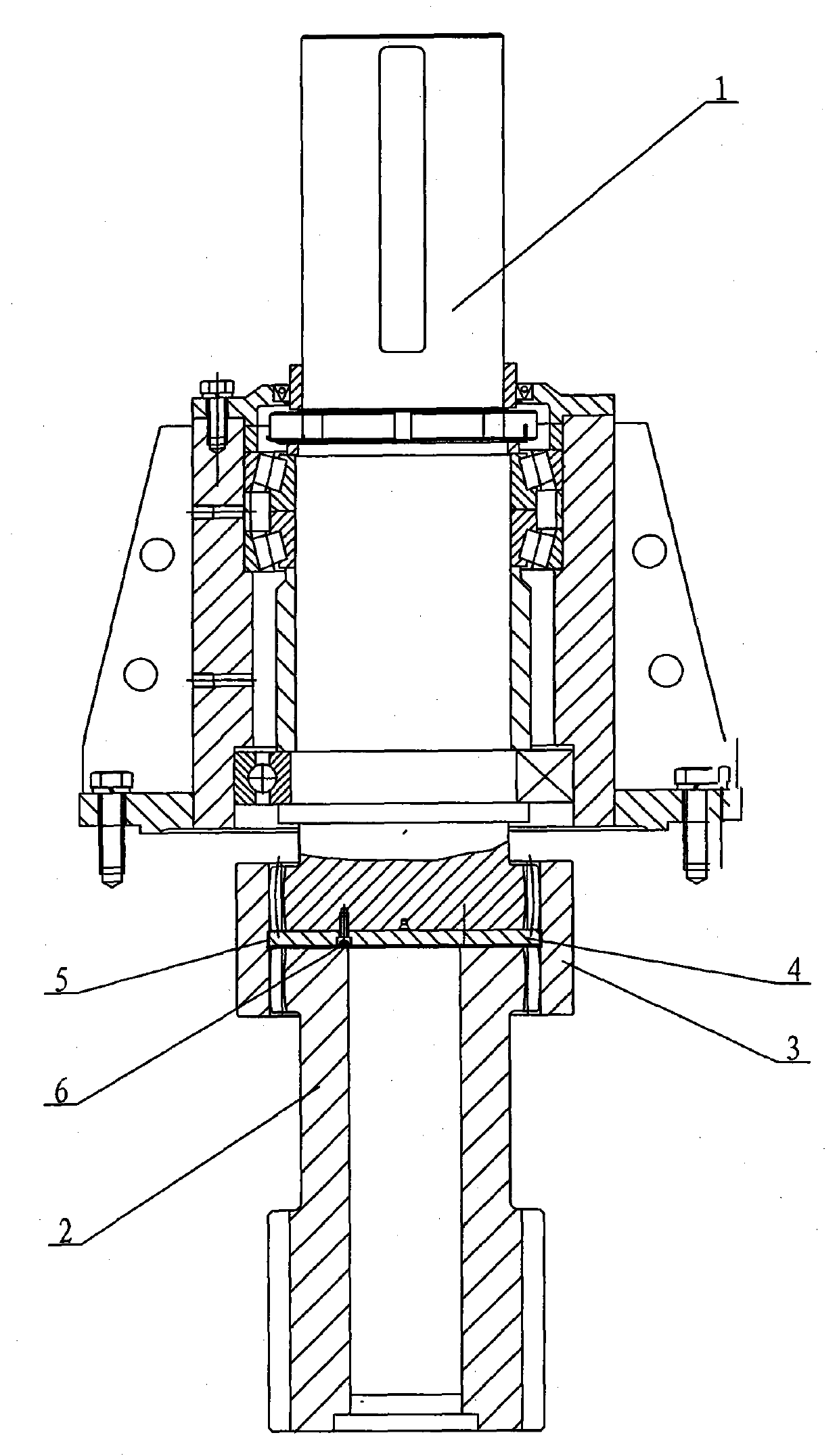

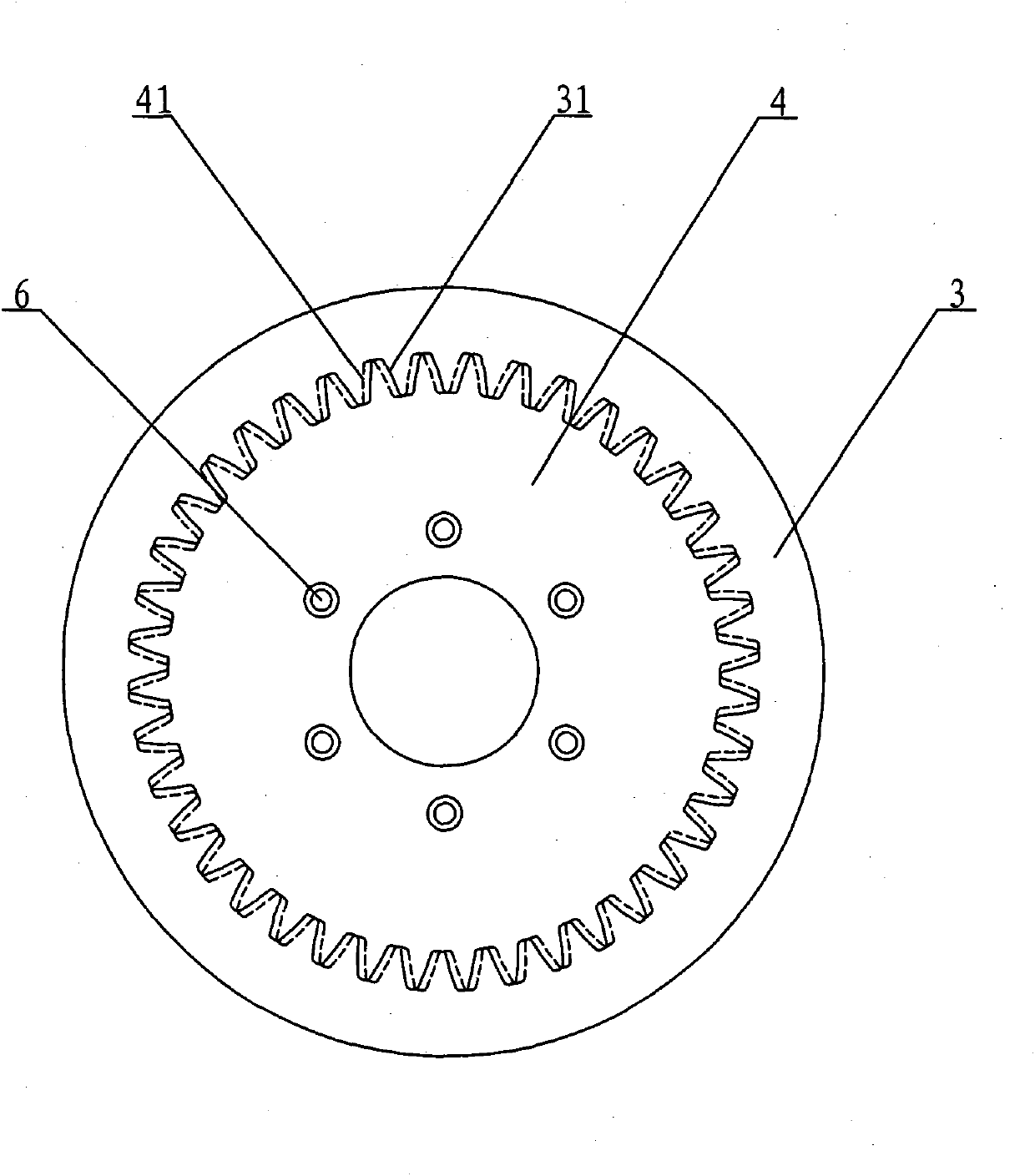

[0014] Figure 1-3 As shown, the toothed baffle floating gear sleeve connection transmission device mainly includes a high-speed shaft 1, a sun gear 2, a floating gear sleeve 3 and a toothed baffle 4. The lower end surface of the high-speed shaft 1 is connected to the floating gear sleeve 3, and the lower end surface of the high-speed shaft is locked and connected to a toothed baffle 4 through screws 6. The outer ring of the toothed baffle 4 is provided with a ring and the inner teeth 31 of the floating gear sleeve 3. The same external teeth 41; the inner ring of the floating gear sleeve 3 is radially and horizontally provided with a circle of limiting grooves 5, the toothed baffle 4 is placed in the limiting groove 5 and the outer teeth 41 of the toothed baffle 4 and the floating gear sleeve 3 The internal teeth 31 of the toothed baffle plate 4 are misplaced with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap