Static sponge method wind load tester of exterior thermal insulation composite system

A technology of external wall insulation and wind load, which is applied to the testing of machines/structural components, instruments, measuring devices, etc., to achieve the effects of accurate testing and uniform and stable tension changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

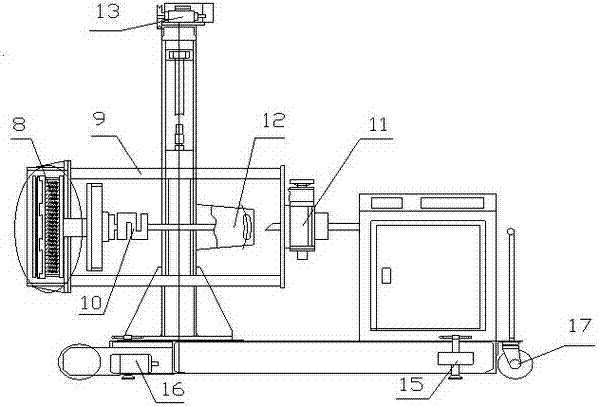

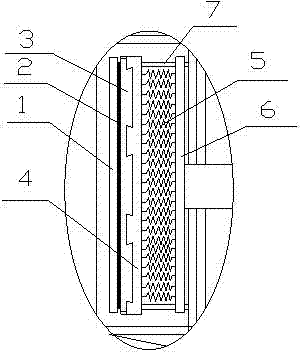

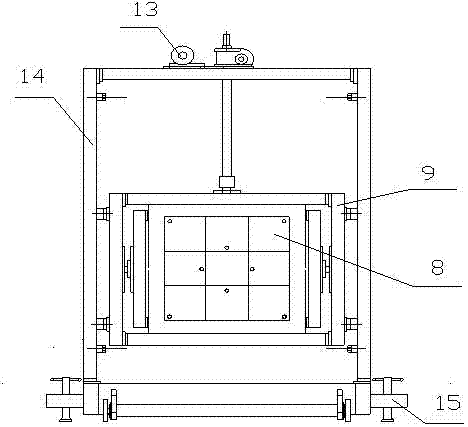

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Such as figure 1 , figure 2 and image 3 The wind load tester for the static sponge method external wall insulation system shown is mainly composed of a testing mechanism and a power mechanism 11 that provides tension to the testing mechanism; The tension panel 8 is composed of; the tension panel 8 includes a silicone sponge board 1, a movable installation board 3, a pull board 4 and a square steel plate 6 in sequence from the outside to the inside, and the silicone sponge board 1 is bonded to the movable installation board 3 by an adhesive 2 The movable mounting plate 3 is provided with a dovetail bump on the opposite side of the bonded silica gel sponge plate 1, and the surface of the pull plate 4 is correspondingly provided with a dovetail groove matching the dovetail bump, and the movable mounting plate 3 passes through the dovetail convex The block is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com