Translation stage capable of containing devices

A built-in translation stage technology, which is applied in the direction of instruments, optical components, installation, etc., can solve the problems of increased volume of the translation stage, difficult occasions with strict volume requirements, and large quality, so as to achieve simple mechanical transmission chain and compact structure , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

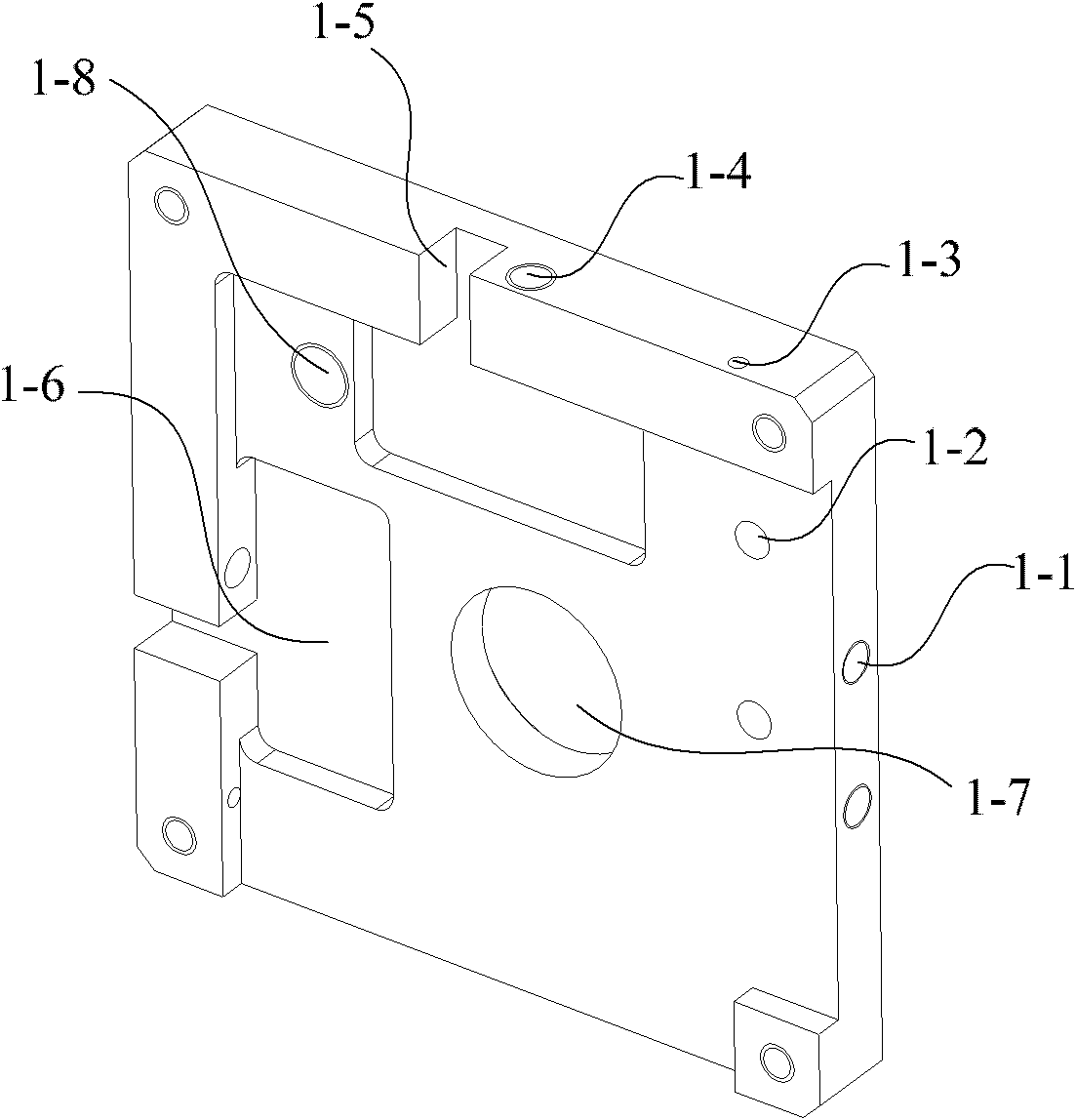

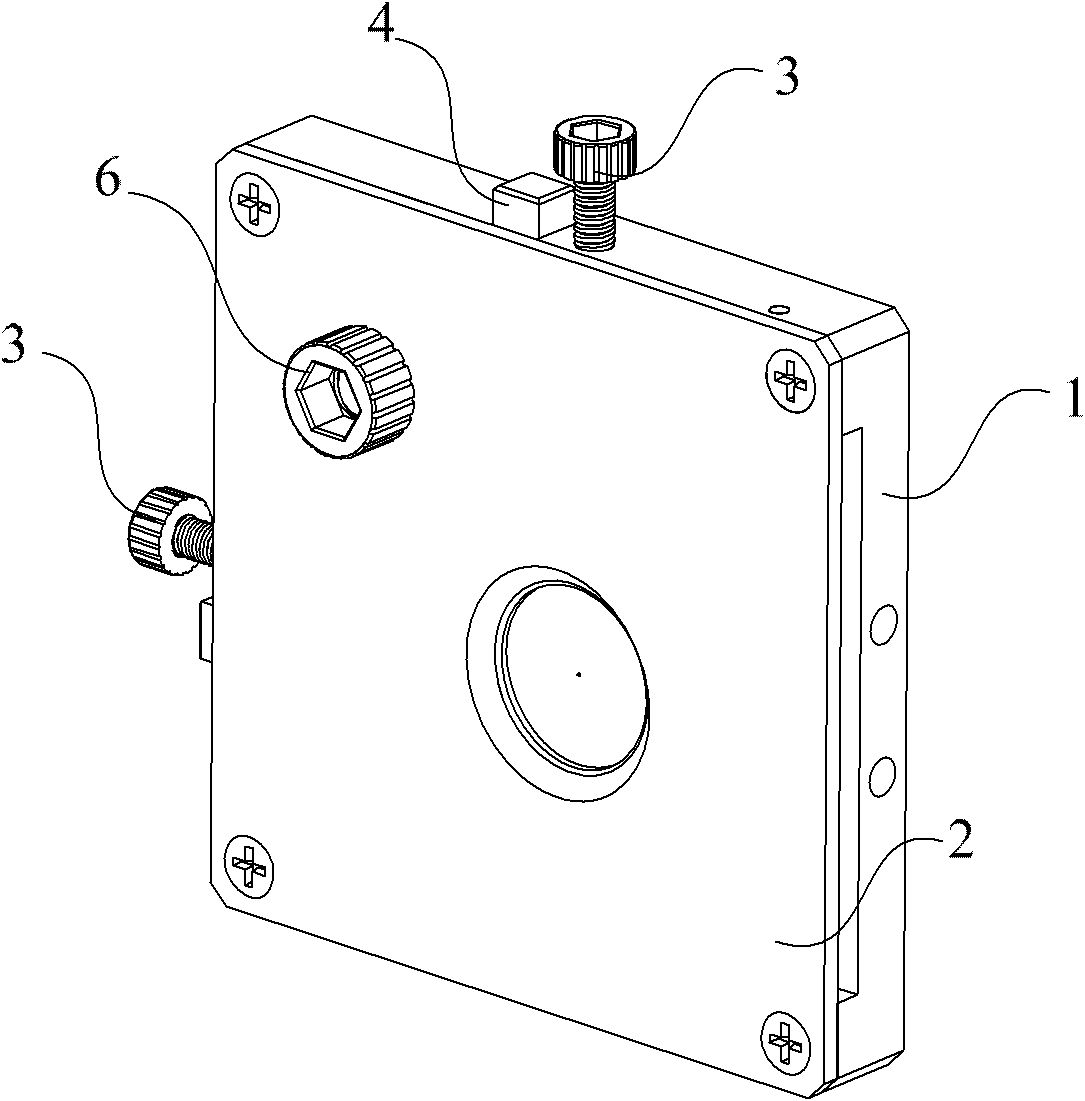

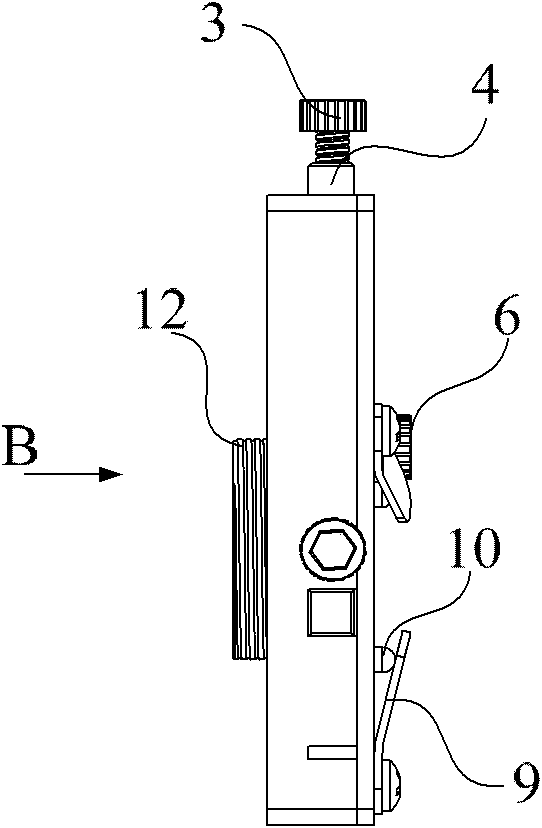

[0032] Such as figure 1 , figure 2 As shown, this embodiment provides a device-built-in two-dimensional translation platform, which is composed of a bottom plate 1 , a cover plate 2 , an adjustment bolt 3 , a push rod 4 , a spring 5 , a locking bolt 6 and a screw 8 .

[0033] Such as figure 2 , Figure 4 As shown, the bottom plate 1 is a square plate structure, with a circular light-transmitting hole 1-7 in the middle, and a locking threaded hole 1-8 and two back mounting holes 1 on both sides of the light-transmitting hole 1-7. -2; There are side mounting holes 1-1 on the two sides of the base plate 1, and adjustment screw holes 1-4, square push rod grooves 1-5 and spring mounting holes 1-3 are provided in the middle of the other two sides of the base plate 1; There is a push rod cavity 1-6 facing the push rod groove 1-5, and the push rod groove 1-5 and the push rod cavity 1-6 constitute the movement space of the push rod 4.

[0034] Such as figure 1 , figure 2 As sh...

Embodiment 2

[0040] Such as Figure 8 As shown, this embodiment provides a three-dimensional translation platform with a built-in device. The translation platform consists of a bottom plate 1, a cover plate 2, an adjustment bolt 3, a push rod 4, a shrapnel 9, a locking bolt 6, a pressure rod 10, and a supporting plate. 11, spring 5, adjusting screw ring 12 and pin 13 are formed.

[0041] Such as Figure 8As shown, the bottom plate 1 is a square cavity structure, with screw holes 1-9 in the middle, back mounting holes 1-2, pin holes 1-10 on the bottom, adjustment screw holes, square push rod grooves, Spring mounting slot. The cover plate 2 is a square plate structure with a circular light-transmitting hole in the middle. In addition, there are three pressure rod holes 2-3 and two pin holes 2-4 on the plate. The push rod 4 is a "T"-shaped structure, and there are two push rods, which are respectively used for adjustment in two directions. There are two adjusting bolts 3, which cooperate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com