Low-loss extra-flexible coaxial cable with embossing insulated by physical foaming and wrapped by copper foil tapes

A physical foaming, coaxial cable technology, applied in the direction of coaxial cable/analog cable, etc., can solve the problems of difficult to achieve large-length continuous production, unable to achieve super flexible effect, poor flexibility, etc. Excellent performance and good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

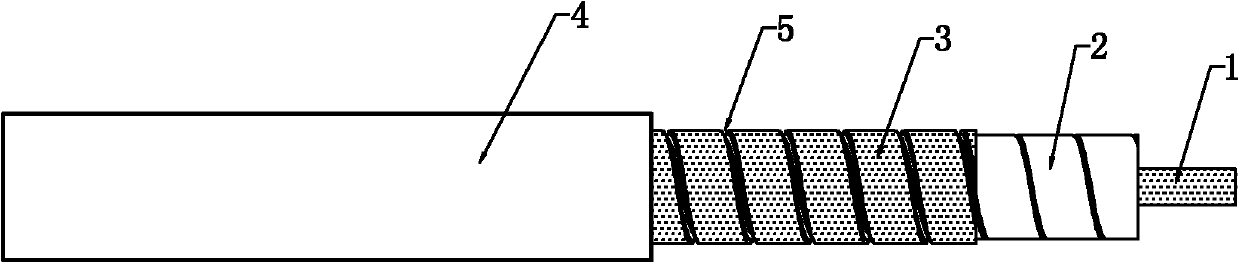

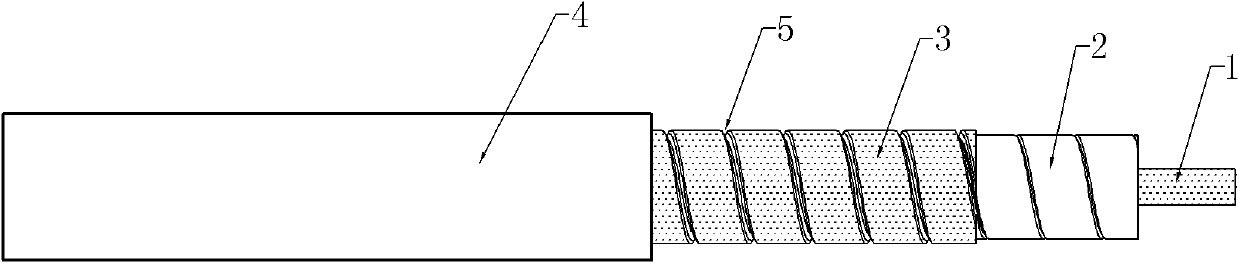

[0010] refer to figure 1 , a low-loss ultra-flexible coaxial cable (take the 50Ω coaxial cable as an example), including a central conductor 1 arranged in sequence from the inside to the outside; a physical foamed polyethylene insulating layer 2; copper foil wrapping or longitudinal Embossed layer 3; outer sheath layer 4, the processing steps include: ①, the central conductor 1 uses pure copper core wire of φ1.12mm; ②, making insulating core wire: A) ingredients, the weight ratio of materials is: brand 50 kg of PE base material of 6944; 50 kg of PE base material of 1253; 1.8 kg of HD101 nucleating agent; among them, the PE base material of 6944 and the PE base material of 1253 are selected from products provided by Dow Chemical Company of the United States , HD101 nucleating agent is provided by Nanjing Huadu Technology Industrial Co., Ltd.; B) mix the above materials; C) foam and extrude the above central conductor 1 and materials on a physical foaming machine to extrude the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com