Exhaust bypass valve for turbocharger

一种涡轮增压器、旁通阀的技术,应用在升阀、阀装置、燃气轮机装置等方向,能够解决控制性恶化等问题,达到抑制转角变动、衰减性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

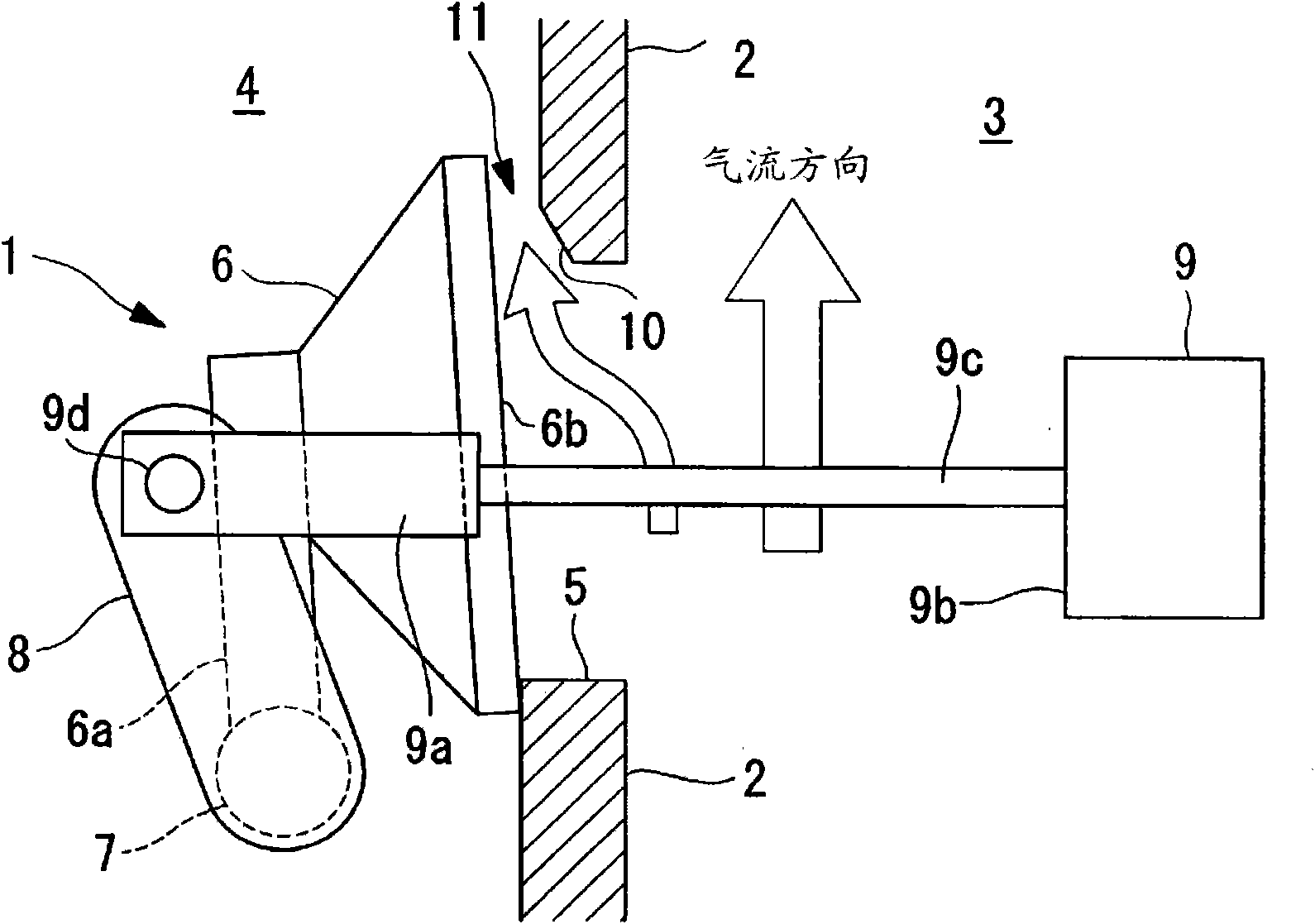

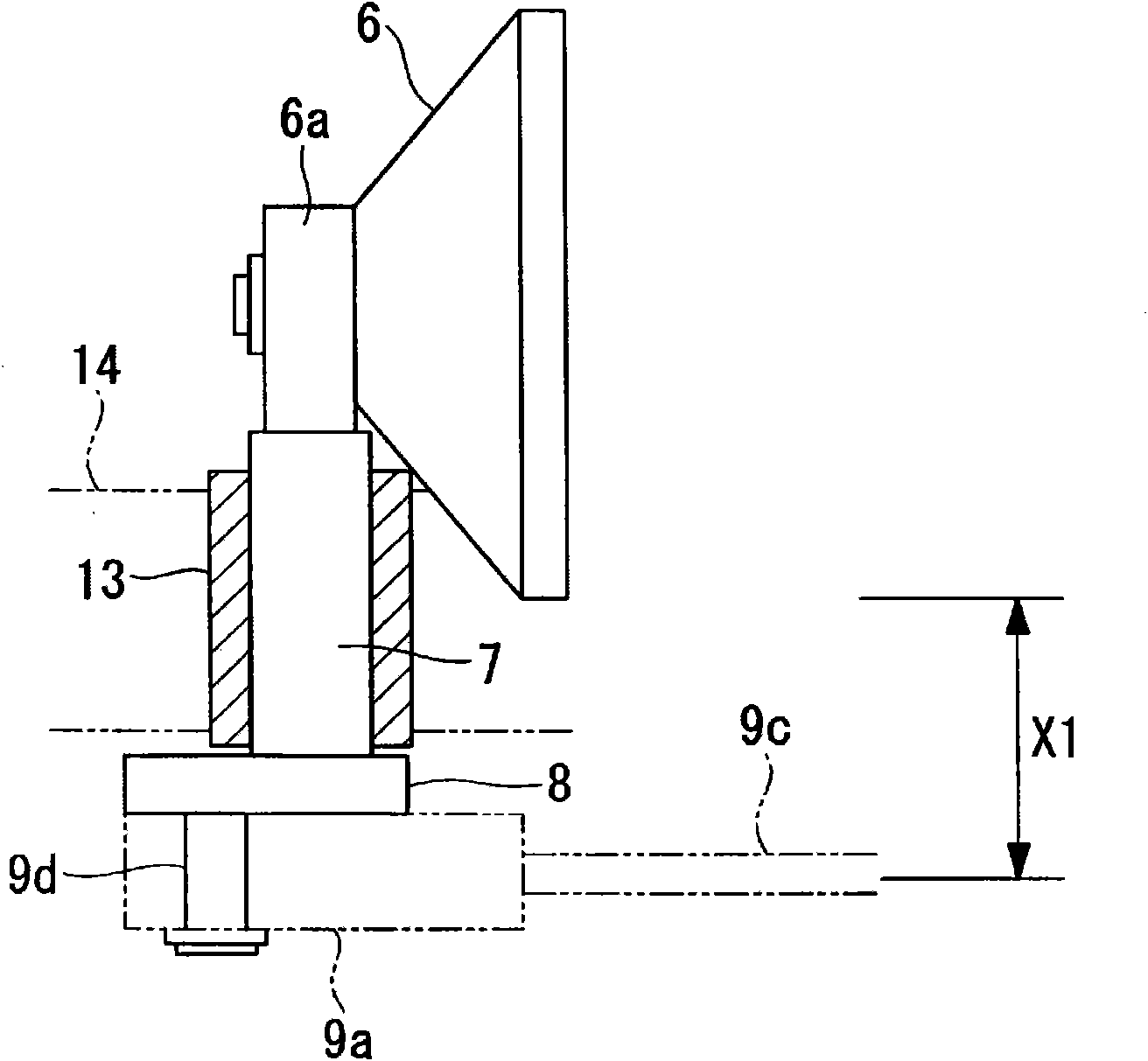

[0087] figure 1 The exhaust bypass valve 1 according to the first embodiment of the present invention is shown. figure 2 It is a plan view in which a part of the exhaust bypass valve 1 is cut away. The illustrated exhaust bypass valve 1 has a structure in which a turbine inlet-side flow path 3 and a turbine outlet-side flow path 4 separated by a partition wall 2 are short-circuited and communicated by a short-circuit flow path 5 . The exhaust bypass valve 1 has a valve flap 6 that covers the short-circuit flow path 5 in a cap-like manner. The valve flap 6 is supported by one end of an arm 6a, and the arm 6a is supported around a shaft 7 as a rotation center. One end of a rod 8 is also fixed to the shaft 7 , and the other end side of the rod 8 is driven to open and close by a driver 9 . The shaft 7 is rotatably supported by a bush 13 , and the bush 13 is fitted to a housing (fixed-side member) 14 . From figure 1 The front side of the paper faces the inner side, and the ...

no. 2 approach

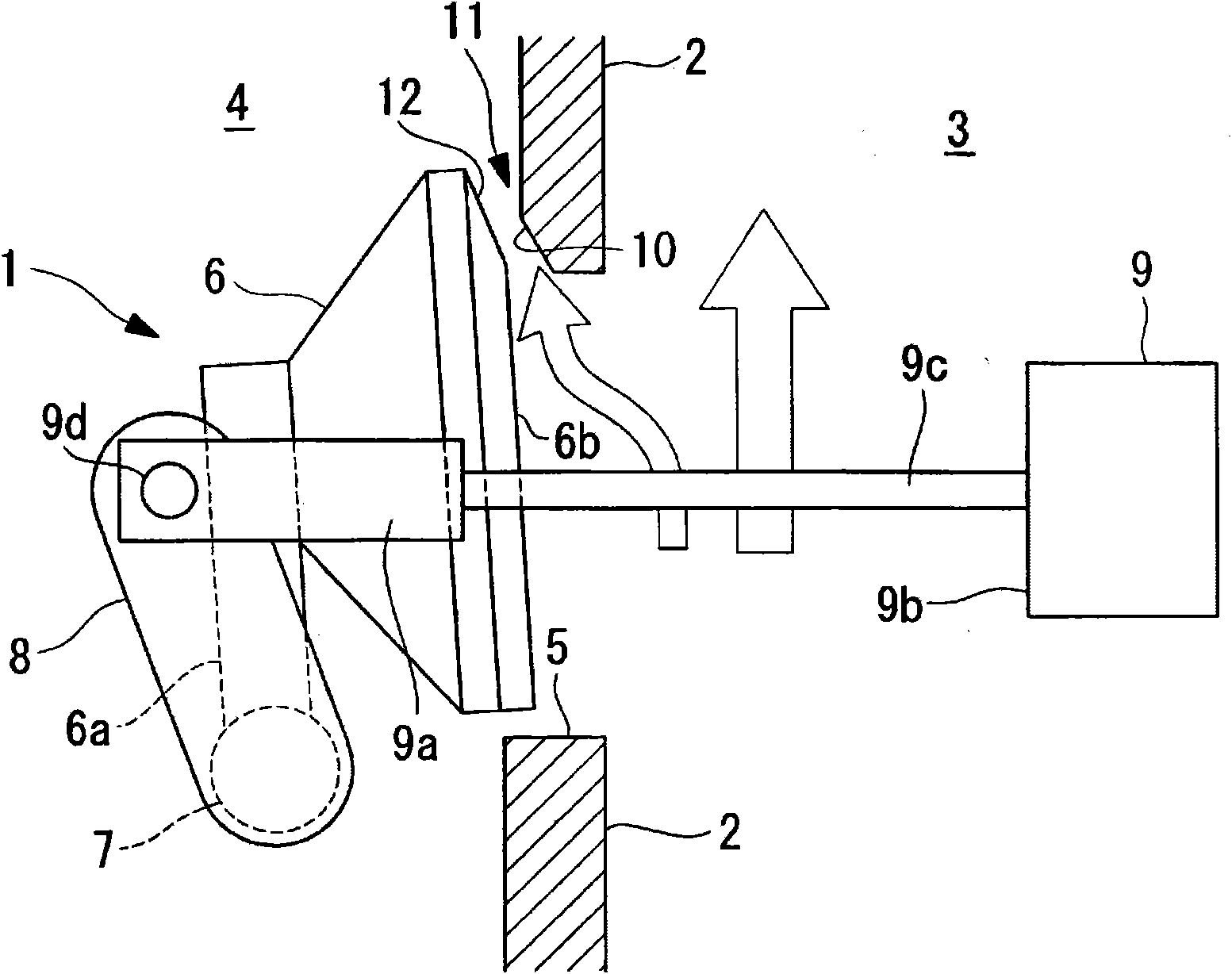

[0094] Figure 5 A wastegate valve 21 according to a second embodiment of the present invention is shown. In addition, the structure of the flap 6 etc. is substantially the same as that of 1st Embodiment mentioned above, and the same code|symbol is used for the same structure, and the description is abbreviate|omitted.

[0095] In the present embodiment, the turbine inlet-side flow path 3 and the turbine outlet-side flow path 4 partitioned by the partition wall 22 are short-circuited and communicated by the short-circuit flow path 25 .

[0096] The short-circuit flow path 25 is inclined so as to approach the rotation axis center side of the shaft 7 from the turbine inlet-side flow path 3 toward the turbine outlet-side flow path 4 . As a result, a pressure increase region 30 is formed at the peripheral wall edge portion of the turbine outlet-side flow path 4 of the short-circuit flow path 25 on the side closer to the shaft 7 .

[0097] According to this structure, the short-c...

no. 3 approach

[0100] Figure 7 An exhaust bypass valve 31 according to a third embodiment of the present invention is shown. In addition, the structure of the flap 6 etc. is substantially the same as that of 1st Embodiment mentioned above, and the same code|symbol is used for the same structure, and the description is abbreviate|omitted.

[0101] In the present embodiment, the turbine inlet-side flow path 3 and the turbine outlet-side flow path 4 partitioned by the partition wall 32 are short-circuited and communicated by the short-circuit flow path 35 .

[0102] The flow passage 3 on the turbine inlet side is approximately parallel to the sealing surface 6b of the disc 6 of the exhaust bypass valve 31 in the vicinity of the exhaust bypass valve 31, and the short-circuit flow passage 35 branches off from the flow passage 3 on the turbine inlet side and flows to the outlet side of the turbine. Road 4 is short-circuited and connected. The short-circuit flow path 35 is inclined in the return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com