Coil PVC (Polyvinyl Chloride) flocked carpet

A coiled material and flocking technology, applied to carpets and other directions, can solve the problems of low technical content, poor flame retardant effect, easy hardening, etc., and achieve the effect of comfortable hand and foot feeling and strong pattern expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

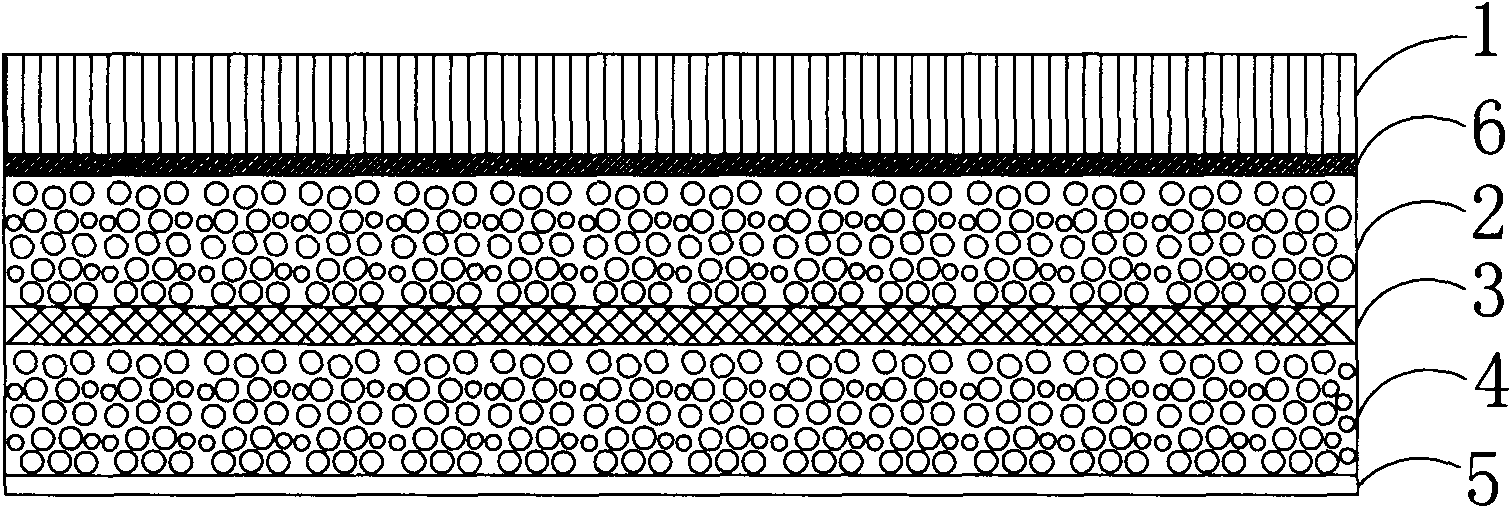

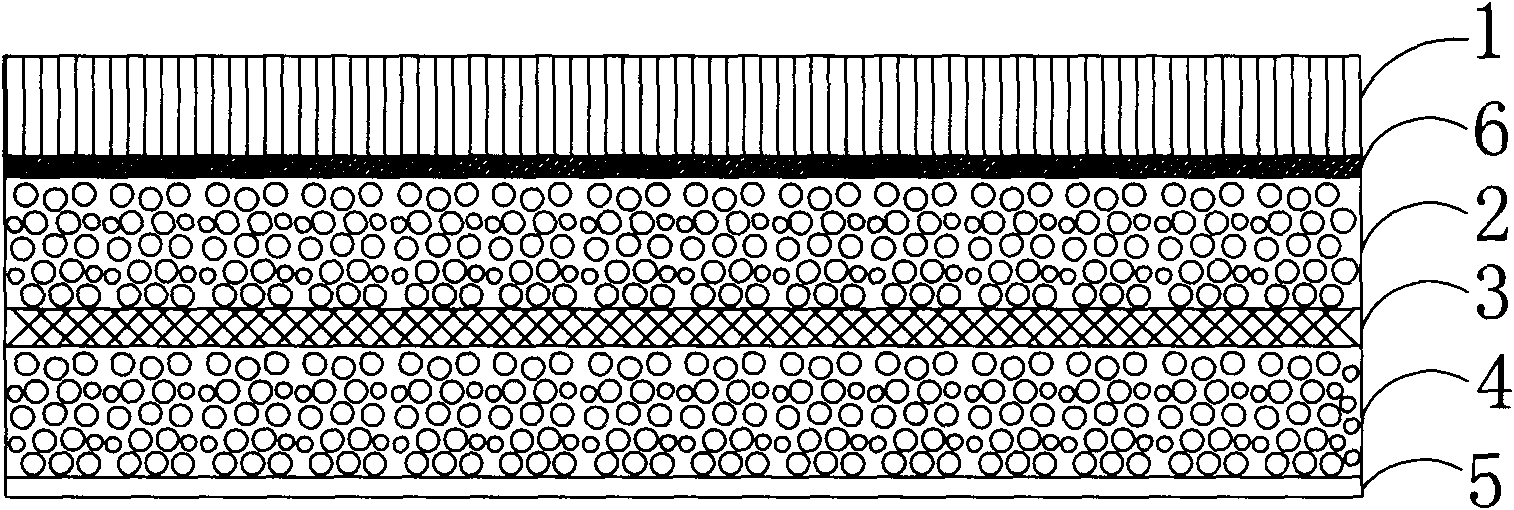

[0027] Embodiment: a kind of roll material PVC flocking carpet, comprise roll material PVC base layer and fluff layer 1, described roll material PVC base layer is made of the first PVC foam layer 2, glass fiber mesh layer 3, the second PVC foam layer 4 and PVC non-slip bottom layer 5, the glass fiber mesh layer is sandwiched between the first and second PVC foam layers, the PVC non-slip bottom layer is fixed on the lower surface of the second PVC foam layer, and the upper surface of the coiled PVC base layer is coated with plant Velvet glue layer 6, the fluff layer is adhered to the upper surface of the PVC base layer of the coiled material through the flocking adhesive layer, and the fluff layer is formed by a dense arrangement of several independent fluffs, and each fluff is vertically adhered to the upper surface of the PVC base layer of the coiled material. The structure formed by sandwiching the glass fiber mesh layer between the first and second PVC foam layers has a dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com