Automatic steam exhausting electric pressure cooker

An electric pressure cooker and steam exhaust technology, which is applied in cooking utensils, household utensils, applications, etc., to expand the scope of application, eliminate potential safety hazards, and achieve the effect of stirring and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

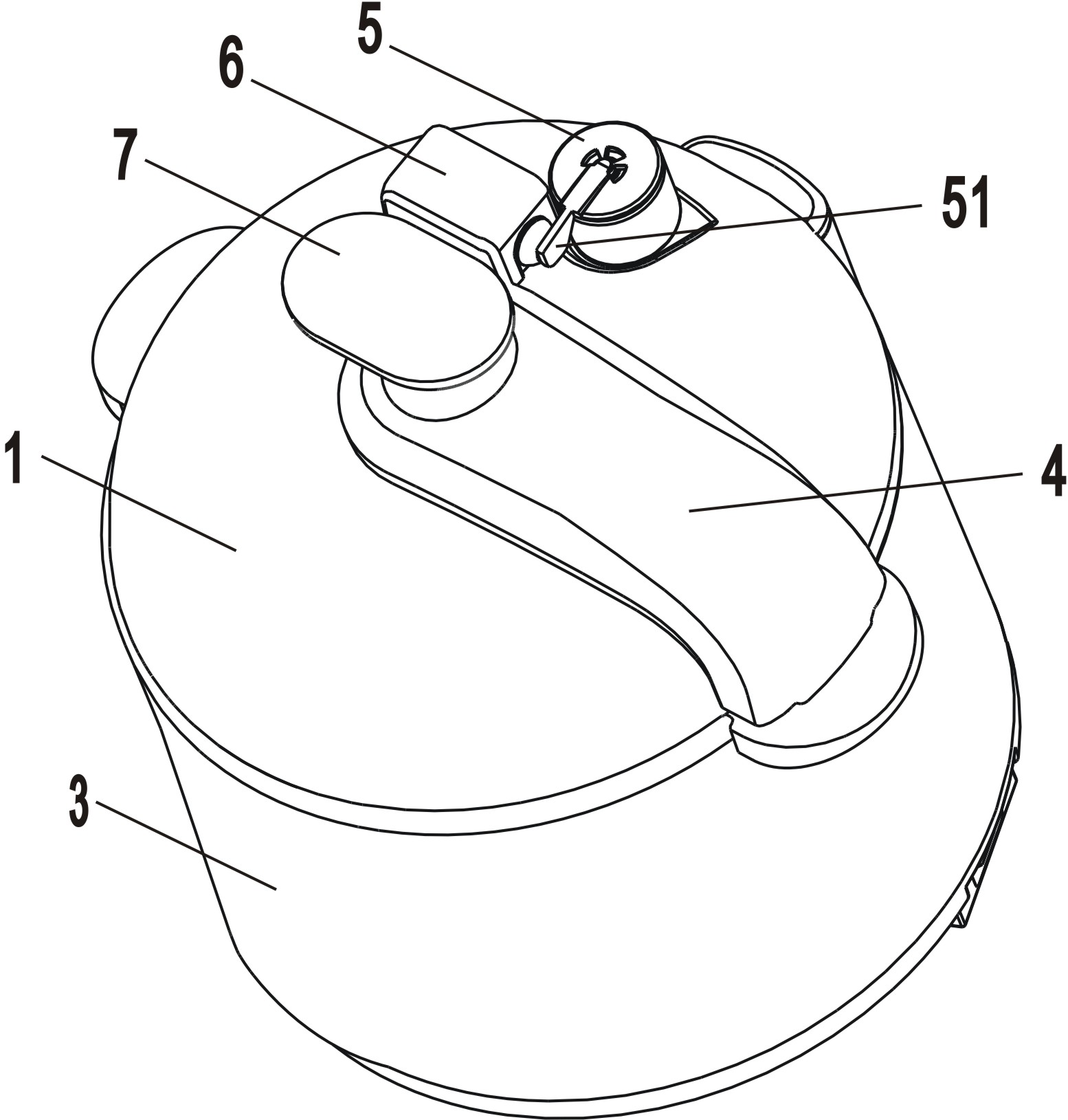

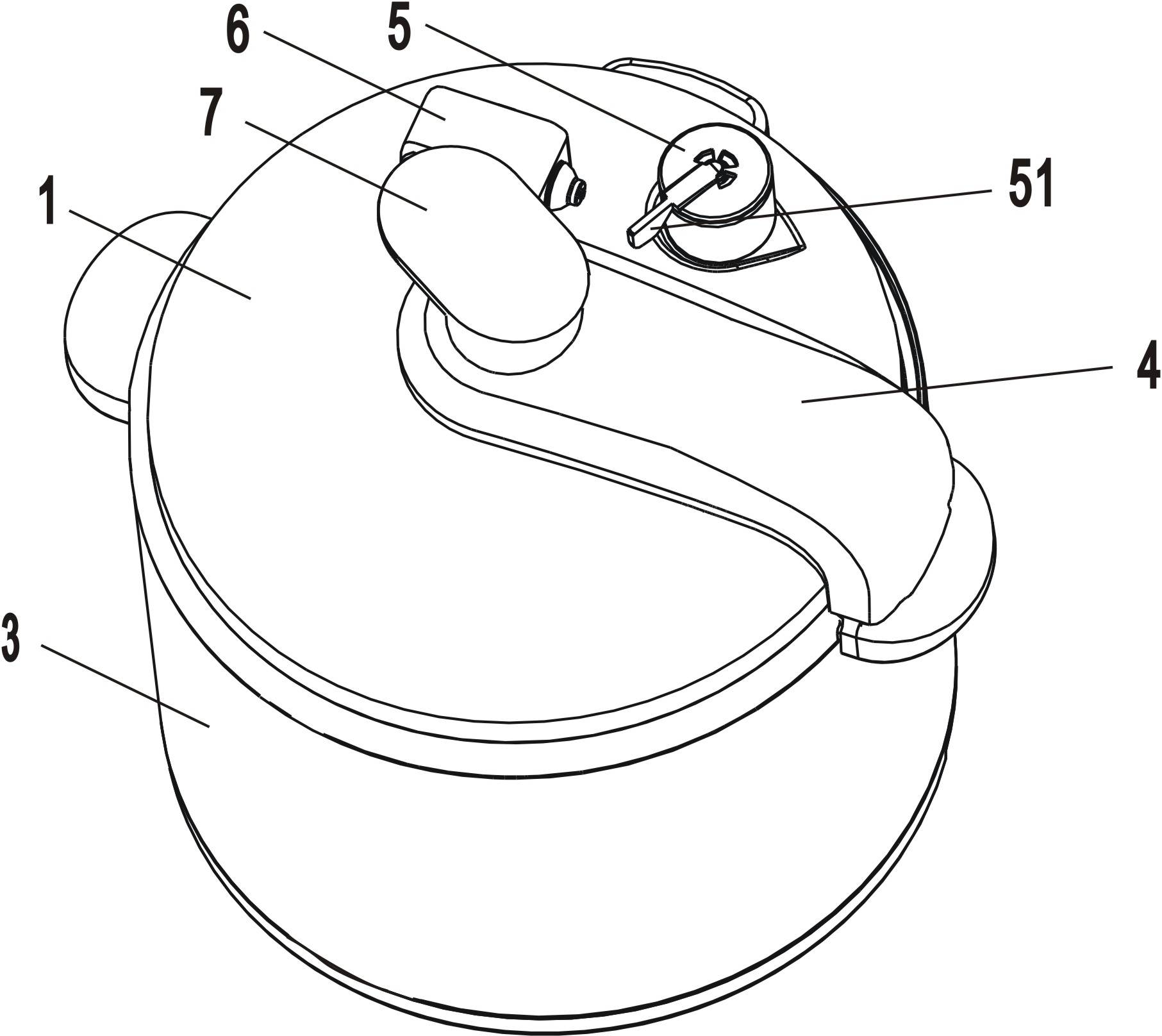

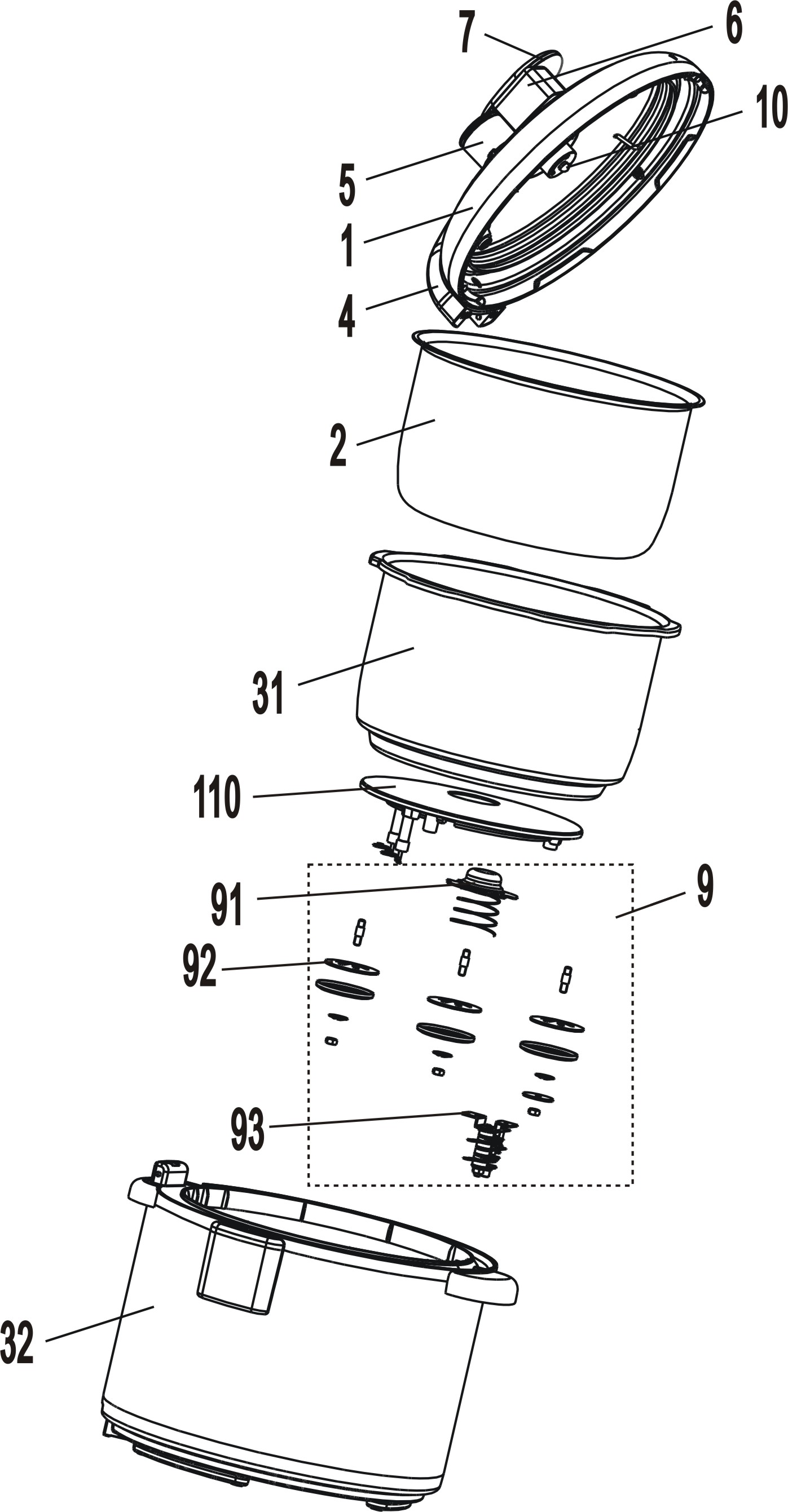

[0036] The technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

[0037] Please refer to Figure 1 to Figure 5 As shown, it is a schematic structural diagram of an embodiment of the present invention. An automatic steam exhaust electric pressure cooker of the present invention includes a lid 1, a pot inner 2, a pot body 3 and a cantilever 4 hinged to the pot body 3. The pot body 3 includes a heat preservation cover 31 and an outer cover 32. The center of the pot cover 1 It is rotatably pivoted to the cantilever 4, the pot cover 1 is fastened or separated from the pot body 3 by rotating, and the handle 7 is fixedly installed on the spin column connecting the pot cover 1 and the cantilever 4. When the handle 7 is rotated, the spin column can be driven. Rotate to drive the pot cover 1 to rotate to be fastened or separated from the pot body 3 . The lid 1 is provided with a hammer-type pressure limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com