Coal shaping roller and automatic shaper applied to transporting coal by trains

A technology of shaping rollers and shapers, which is applied in the directions of transportation and packaging, loading/unloading, shafts and bearings, etc. It can solve the problems of high labor intensity, failure to meet railway requirements, low work efficiency, etc., and achieve simple operation and save time and manpower, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

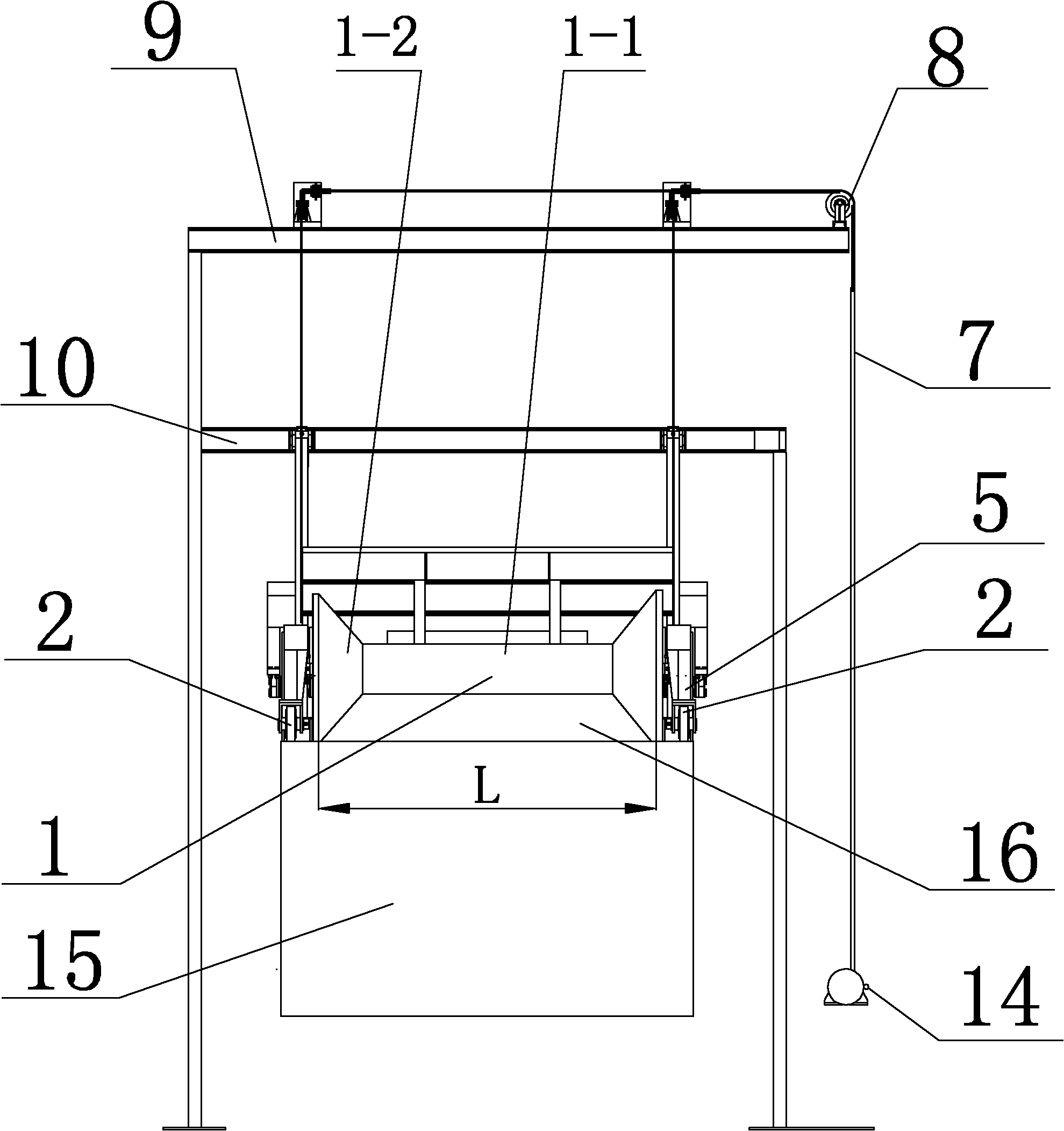

[0023] Specific implementation mode one: as figure 2 and Figure 8 As shown, the coal shaping roller 1 described in this embodiment is composed of two truncated cones 1-2 and a cylinder 1-1 located between the two truncated cones 1-2, and the three are coaxially arranged. The cylinder 1- The two ends of 1 are respectively fixedly connected with the small end of a conical body 1-2; and the diameter of the small end face of the conical body 1-2 is the same as the outer diameter (diameter) of the cylinder 1-1; the coal shaping roller The length L of 1 is consistent with the width of the train compartment cavity.

specific Embodiment approach 2

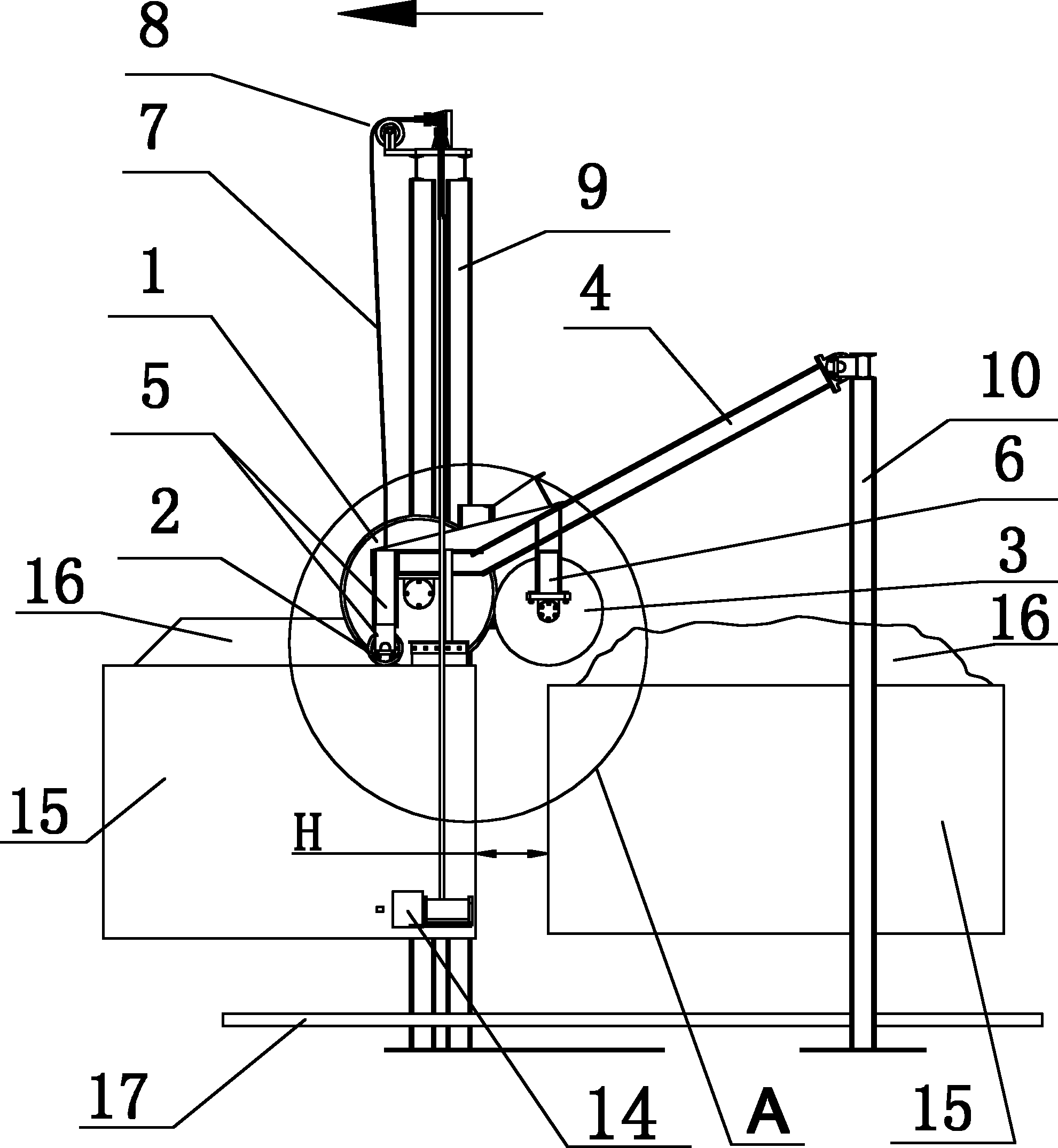

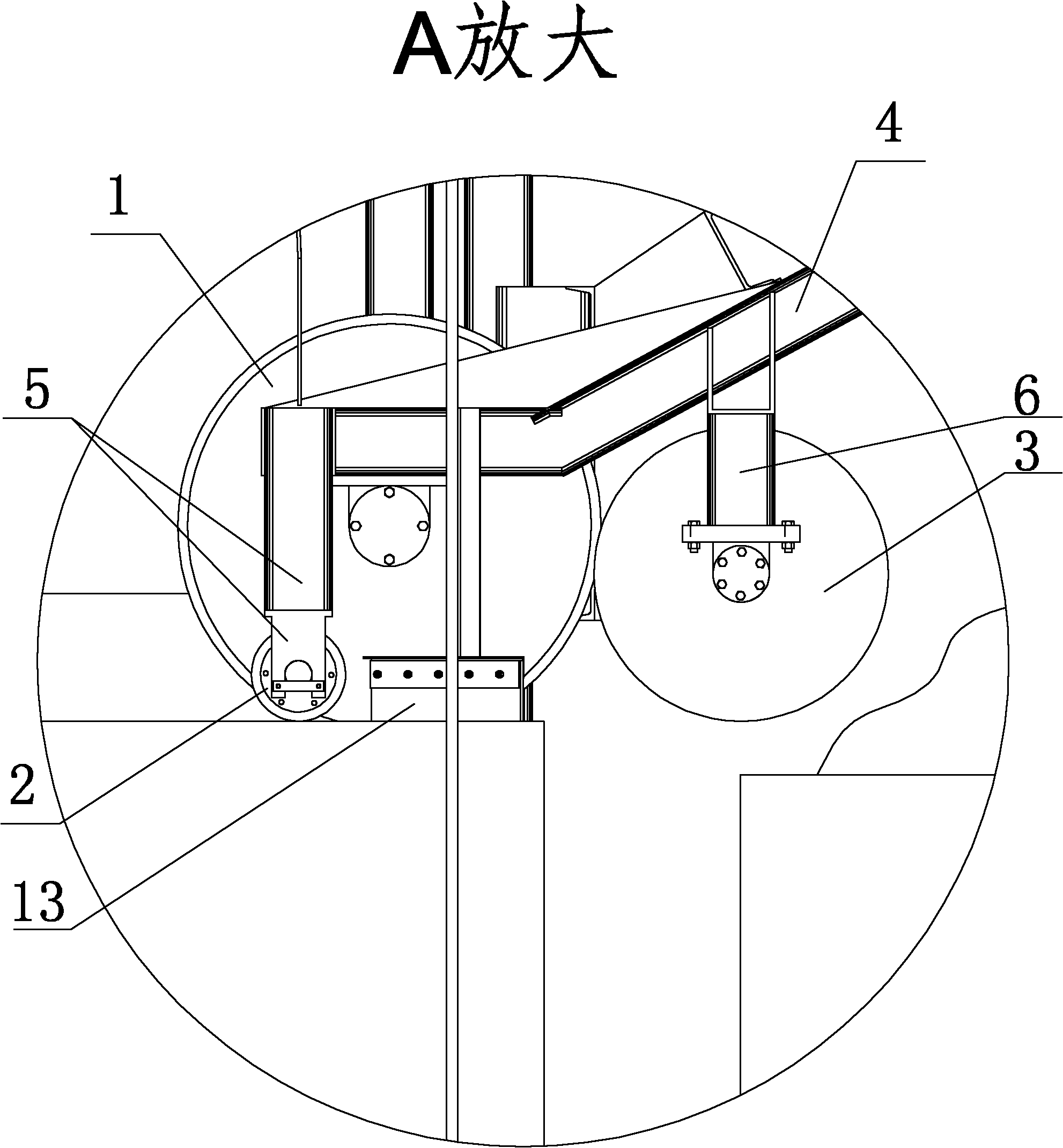

[0024] Specific implementation mode two: as Figure 1-10 As shown, the automatic shaper suitable for coal transport by train containing the coal shaping roller described in Embodiment 1 of this embodiment includes a coal shaping roller 1, two flat car height adjustment wheels 2, and two transition guide wheels 3 and two cantilever beams 4; the coal shaping roller 1 is arranged between the ends of the two cantilever beams 4, and the large end face of the conical body 1-2 on one end of the coal shaping roller 1 is connected with a cantilever beam 4, and the coal shaping roller 1 The large end face of the round table body 1-2 on the other end is connected with another cantilever beam 4, and the two ends of the coal shaping roller 1 are respectively provided with a flat car height adjustment wheel 2, and the two flat car height adjustment wheels 2 axes are aligned with the coal The axes of the shaping rollers 1 are parallel; each flatcar height adjustment wheel 2 is connected to the...

specific Embodiment approach 3

[0025] Specific implementation mode three: as Figure 1-7 As shown, the automatic shaper in this embodiment also includes a lifting device, and the lifting device includes a wire rope group 7, a pulley block 8, a lifting frame 9 and a swing frame 10, and the coal shaping roller 1 is placed in the lifting frame 9, swinging The frame 10 is arranged behind the lifting frame 9, the root ends of the two cantilever beams 4 are respectively hinged with the upper beam of the swinging frame 10, the pulley block 8 is installed on the lifting frame 9, and the ends of the two cantilever beams 4 are connected to the wire rope group 7 , the coal shaping roller 1 realizes the up and down translation of the coal shaping roller 1 by the wire rope group 7 wound on the pulley block 8 (that is, when the coal shaping roller 1 moves up and down, its axis is always parallel to the cross section of the train car). Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com