Horizontal continuous polymerization reaction kettle for producing rubber powder modified bitumen

A polymerization reaction kettle and modified asphalt technology, which is applied in building components, building insulation materials, buildings, etc., can solve problems such as difficult control, many production equipment, and leaking tanks, and achieve the effect of reducing energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

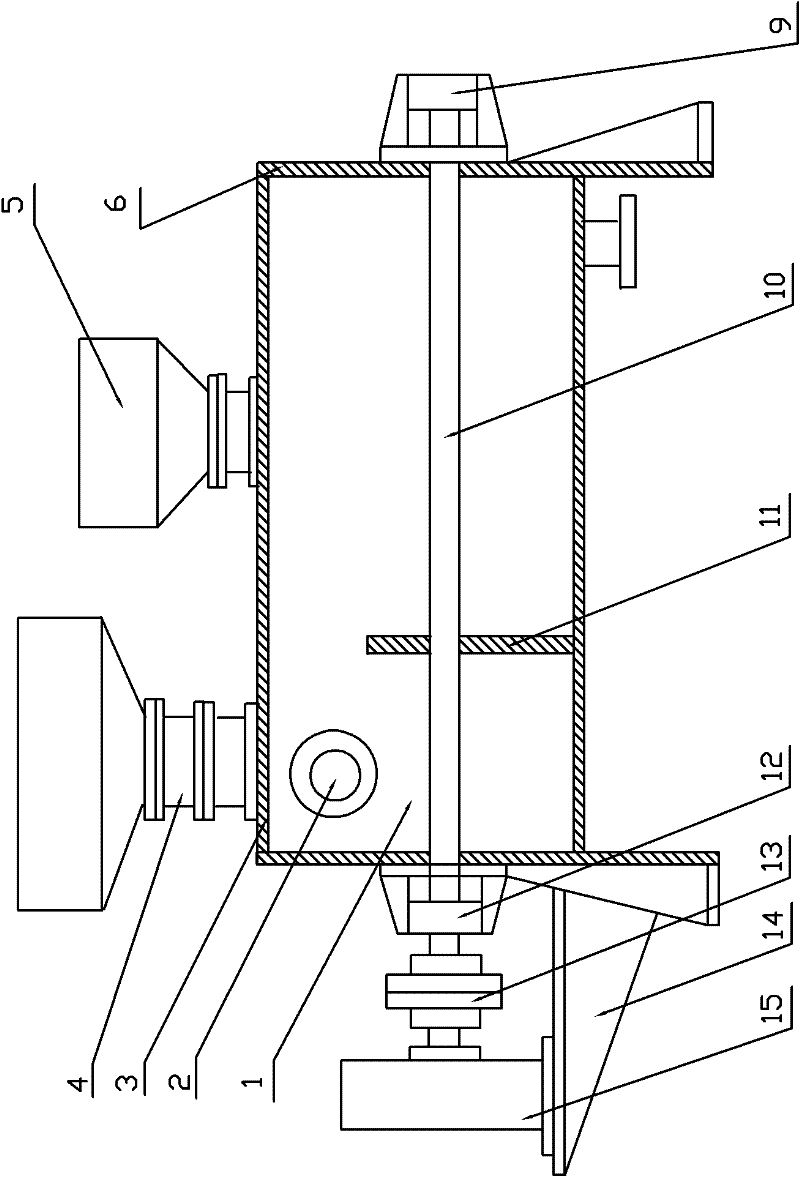

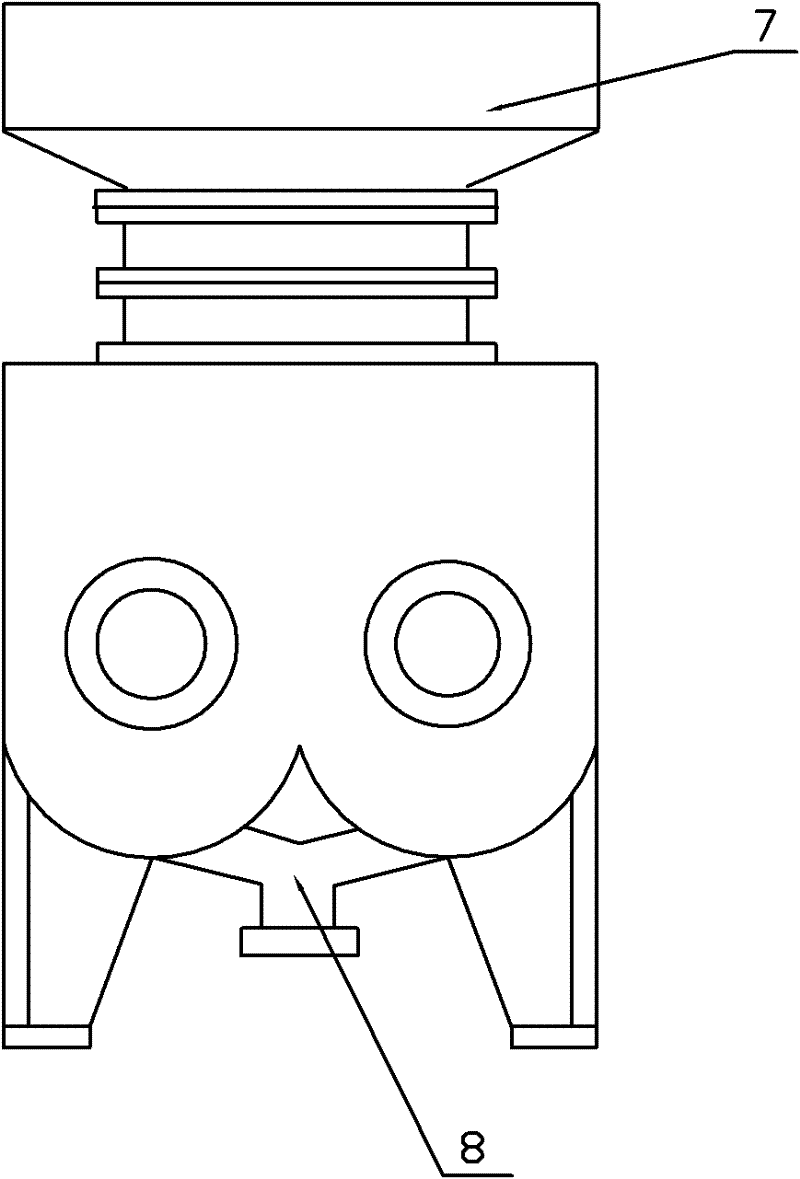

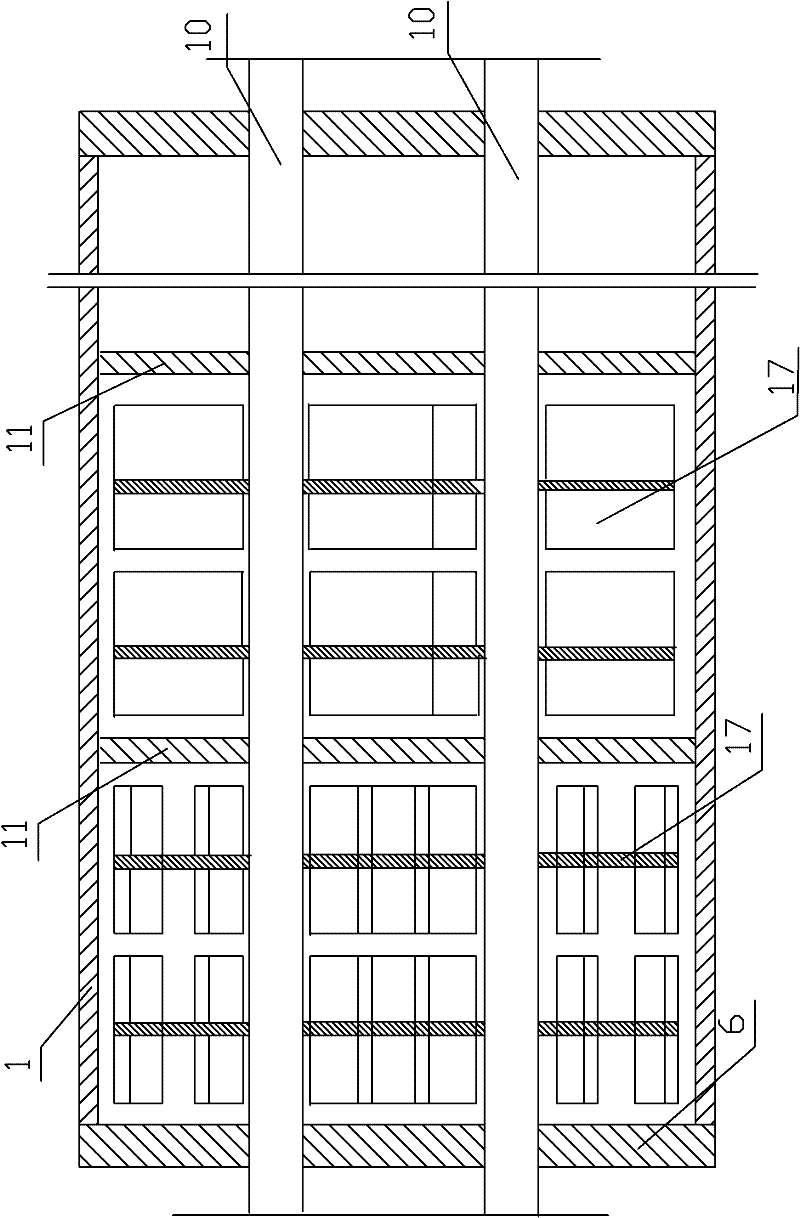

[0015] The specific implementation of the present invention will be described in detail below in conjunction with the drawings and preferred embodiments. As shown in the figure, a horizontal continuous polymerization reactor for producing rubber powder modified asphalt is mainly composed of the reactor body 1, the rubber powder feeding distributor 4, the additive silo 5, the rubber powder storage silo 7, and the stirring shaft 10. It is composed of a deceleration device, and the rubber powder storage bin 7 is connected with the rubber powder dispenser 4 to ensure that the rubber powder is evenly distributed. The upper cover 3 of the reactor body is respectively fixed with an additive silo 5, a rubber powder dispenser and an additive silo communicating with its inner cavity. The front of the reactor body is provided with a matrix asphalt inlet 2 and the bottom of the reactor body is provided with a finished product outlet 8; Front and rear bearing boxes 12 and 9 are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com